Infiniti FX35 / FX45. Manual - part 822

BULB SPECIFICATIONS

LT-183

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

M

A

B

LT

N

O

P

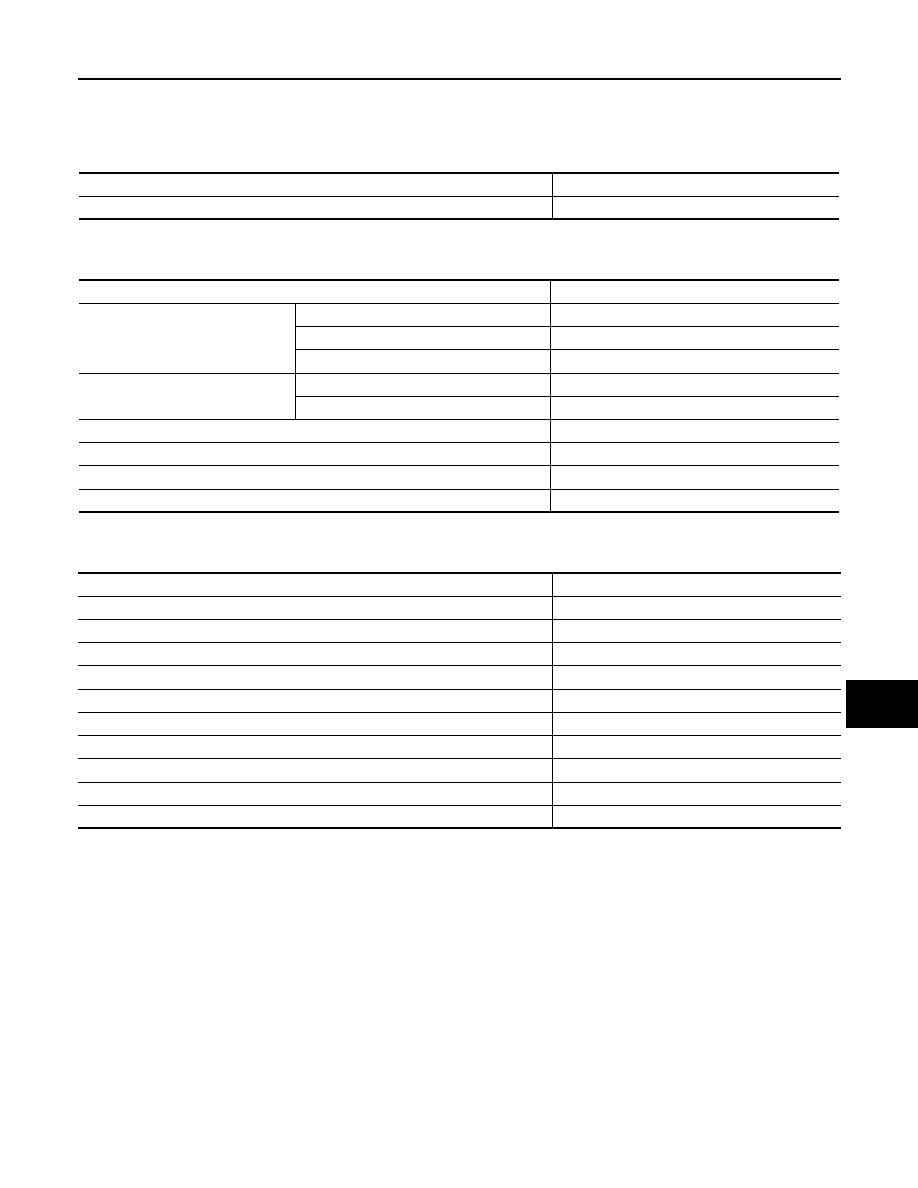

BULB SPECIFICATIONS

Headlamp

INFOID:0000000001328429

Exterior Lamp

INFOID:0000000001328430

Interior Lamp/Illumination

INFOID:0000000001328431

Item

Wattage (W)

High/Low (Xenon type)

35 (D2S)

Item

Wattage (W)

Front combination lamp

Front turn signal lamp

21 (amber)

Daytime/Parking lamp

21/5

Front side marker lamp

3.8

Rear combination lamp

Stop/Tail lamp and Rear Turn signal lamp

LED

Rear side marker lamp

3.8

Front fog lamp

35 (H8)

Back-up lamp

18

License plate lamp

5

High-mounted stop lamp (back door mount)

LED

Item

Wattage (W)

Map lamp

8

Interior room lamp

10

Personal lamp

8

Luggage room lamp

8

Step lamp

5

Glove box lamp

1.4

Vanity mirror lamp

1.32

Ignition key hole illumination

0.8

A/T device illumination lamp

1.4

Coin box illumination lamp

1.4