Infiniti FX35 / FX45. Manual - part 706

FFD-34

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

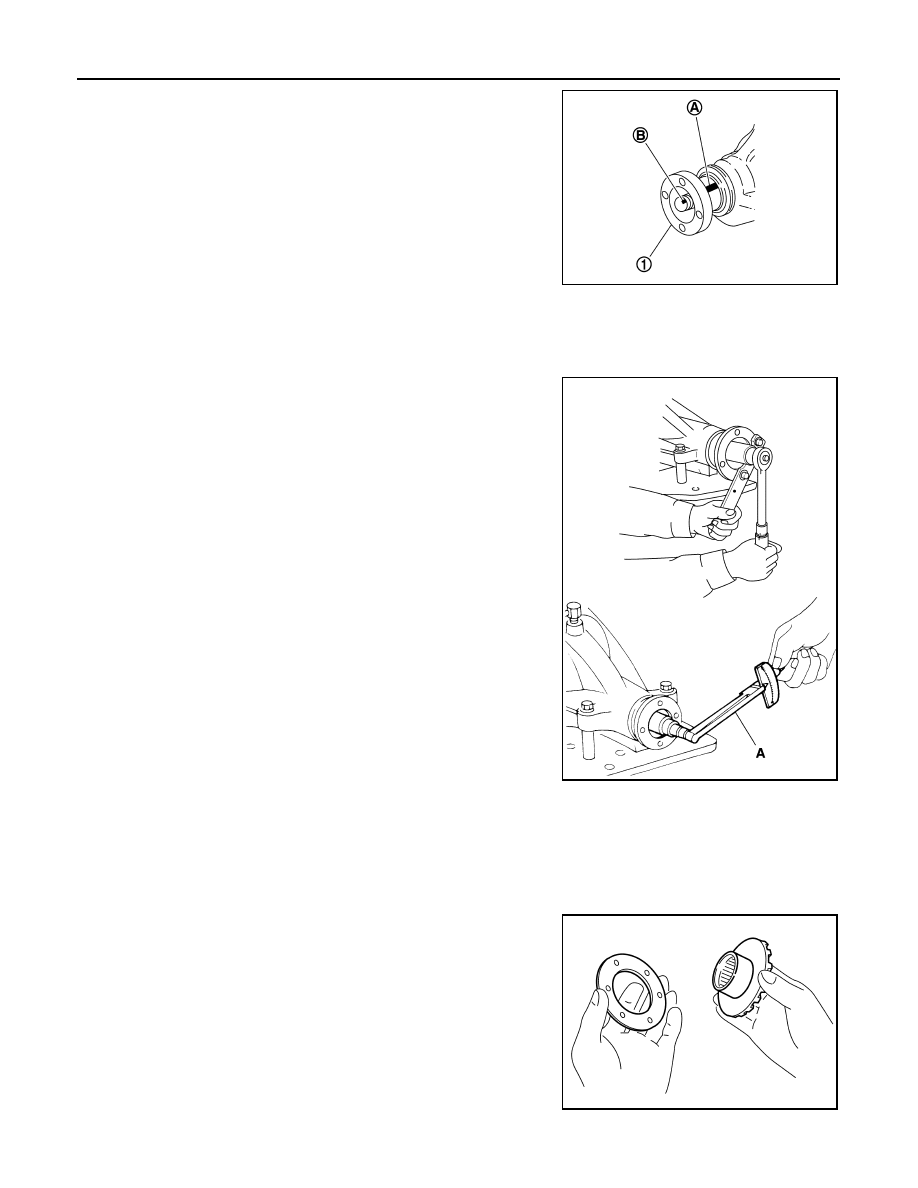

10. Install companion flange (1).

NOTE:

When reusing drive pinion, align the matching mark (B) of drive

pinion with the matching mark (A) of companion flange, and then

install companion flange (1).

11. Apply anti-corrosion oil to the thread and seat of new drive pinion lock nut, and temporarily tighten drive

pinion lock nut to drive pinion.

CAUTION:

Never reuse drive pinion lock nut.

12. Tighten to drive pinion lock nut, while adjust pinion bearing pre-

load torque.

CAUTION:

• Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

• After adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

13. Install differential case assembly. Refer to "Differential Assem-

bly".

CAUTION:

Never install carrier cover yet.

14. Check and adjust drive gear runout, tooth contact, drive gear to

drive pinion backlash, and companion flange runout. Refer to

"Drive Gear Runout", "Tooth Contact", "Backlash", "Companion Flange Runout".

Recheck above items. Readjust the above description, if necessary.

15. Check total preload torque. Refer to "Total Preload Torque".

16. Install carrier cover. Refer to "Differential Assembly".

Differential Assembly

1.

Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly or reinstall the old ones on

the side gears.

PDIA0799J

Tool number

A: ST3127S000 (J-25765-A)

Drive pinion lock nut tightening torque:

127.4 - 245.0 N·m (13.0 - 25.0 kg-m, 94 - 181 ft-lb)

Pinion bearing preload:

0.78 - 1.57 N·m (0.08 - 0.16 kg-m, 7 - 13 in-lb)

PDIA0802J

SDIA0193J