Infiniti FX35 / FX45. Manual - part 704

FFD-26

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

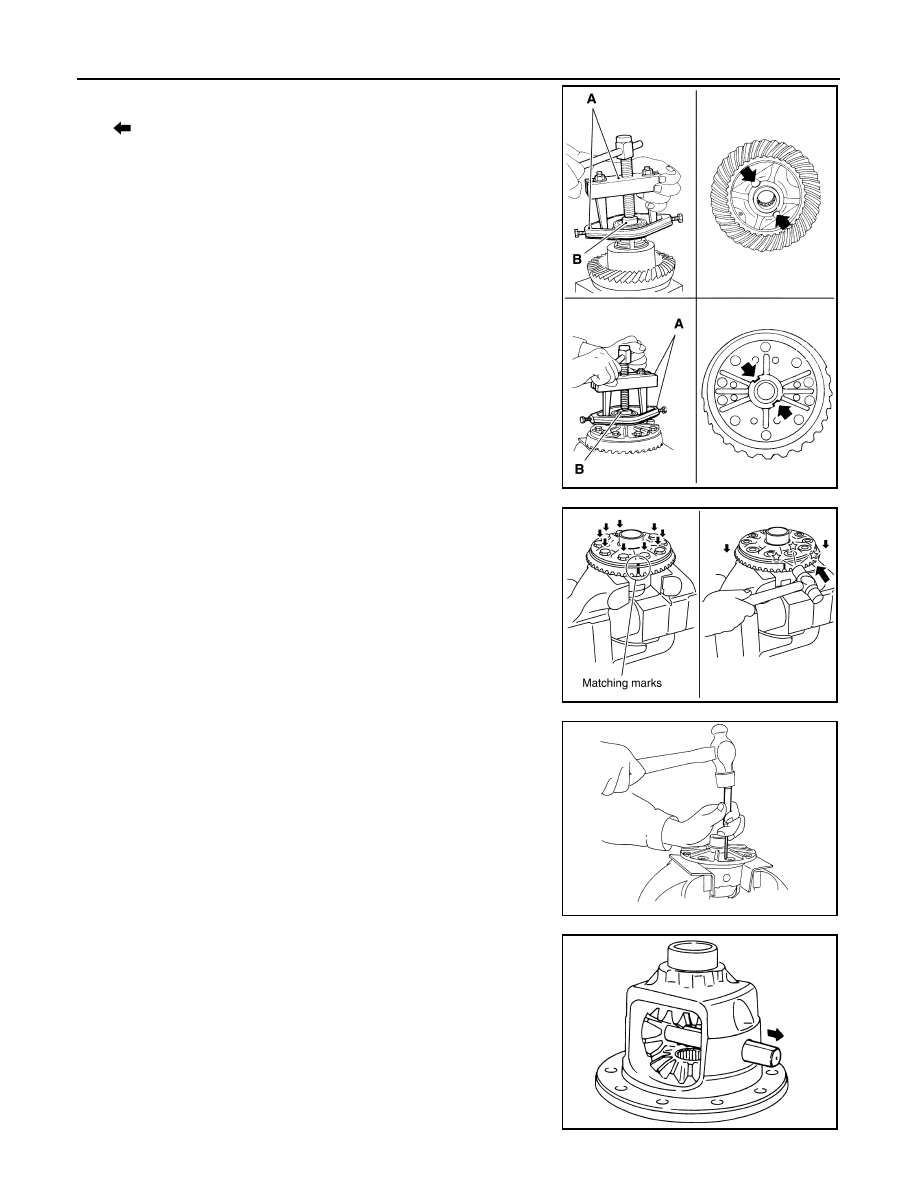

13. Remove side bearing inner race.

To prevent damage to bearing, engage puller jaws in groove

(

).

CAUTION:

• To prevent damage to the side bearing and drive gear,

place copper plates between these parts and vise.

• It is not necessary to remove side bearing inner race

except it is replaced.

14. For proper reinstallation, paint matching marks on one differen-

tial case assembly.

CAUTION:

For matching marks, use paint. Never damage differential

case and drive gear.

15. Remove drive gear mounting bolts.

16. Tap drive gear off differential case assembly with a soft hammer.

CAUTION:

Tap evenly all around to keep drive gear from bending.

17. Remove lock pin of pinion mate shaft with a punch from drive

gear side.

18. Remove pinion mate shaft.

Tool number

A: ST33051001 (J-22888-20)

B: ST33061000 (J-8107-2)

PDIA0758J

PDIA0496E

PDIA0759J

SDIA0031J