Infiniti FX35 / FX45. Manual - part 651

ENGINE ASSEMBLY

EM-121

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

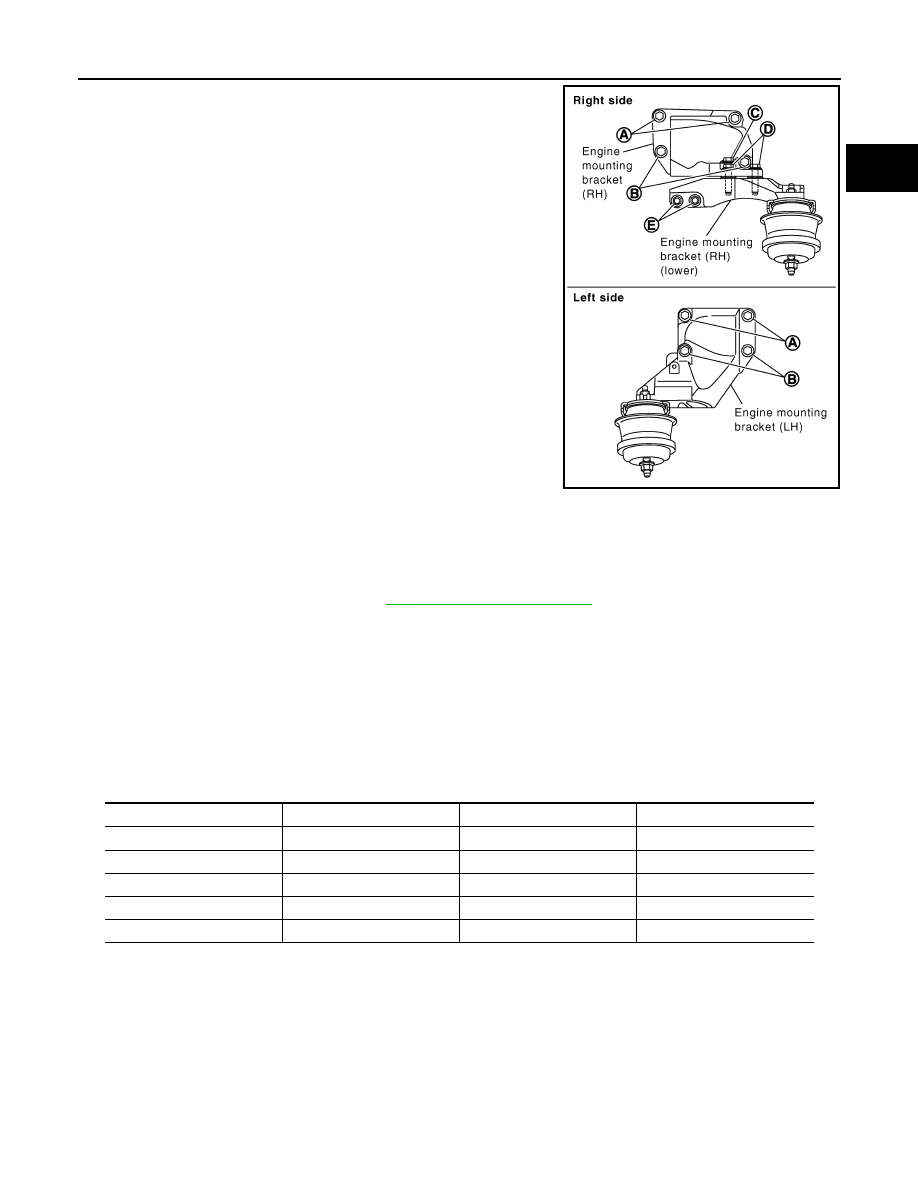

• When installing engine mounting bracket (RH and LH) on cylinder

block, tighten two upper bolts (shown as “A” in the figure) first.

Then tighten two lower bolts (shown as “B” in the figure).

• Install engine mounting bracket (RH) (lower) as follows:

- Temporarily tighten mounting bolts (shown as “C”, “D” and “E” in

the figure).

- Tighten mounting bolts to the specified torque with following

mounting surfaces touched.

• Engine mounting bracket (RH) to engine mounting bracket (RH)

(lower) (shown as “C” and “D” in figure).

• Front final drive to engine mounting bracket (RH) (lower) (shown

as “E” in figure).

• Make sure all engine mounting insulators are seated properly, then

tighten mounting nuts.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

.

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid. power steering fluid, brake fluid, etc.

PBIC3042E

Items

Before starting engine

Engine running

After engine stopped

Engine coolant

Level

Leakage

Level

Engine oil

Level

Leakage

Level

Other oils and fluid*

Level

Leakage

Level

Fuel

Leakage

Leakage

Leakage

Exhaust gases

—

Leakage

—