Infiniti EX35. Manual - part 895

COMPRESSOR

HA-39

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

ON-VEHICLE REPAIR

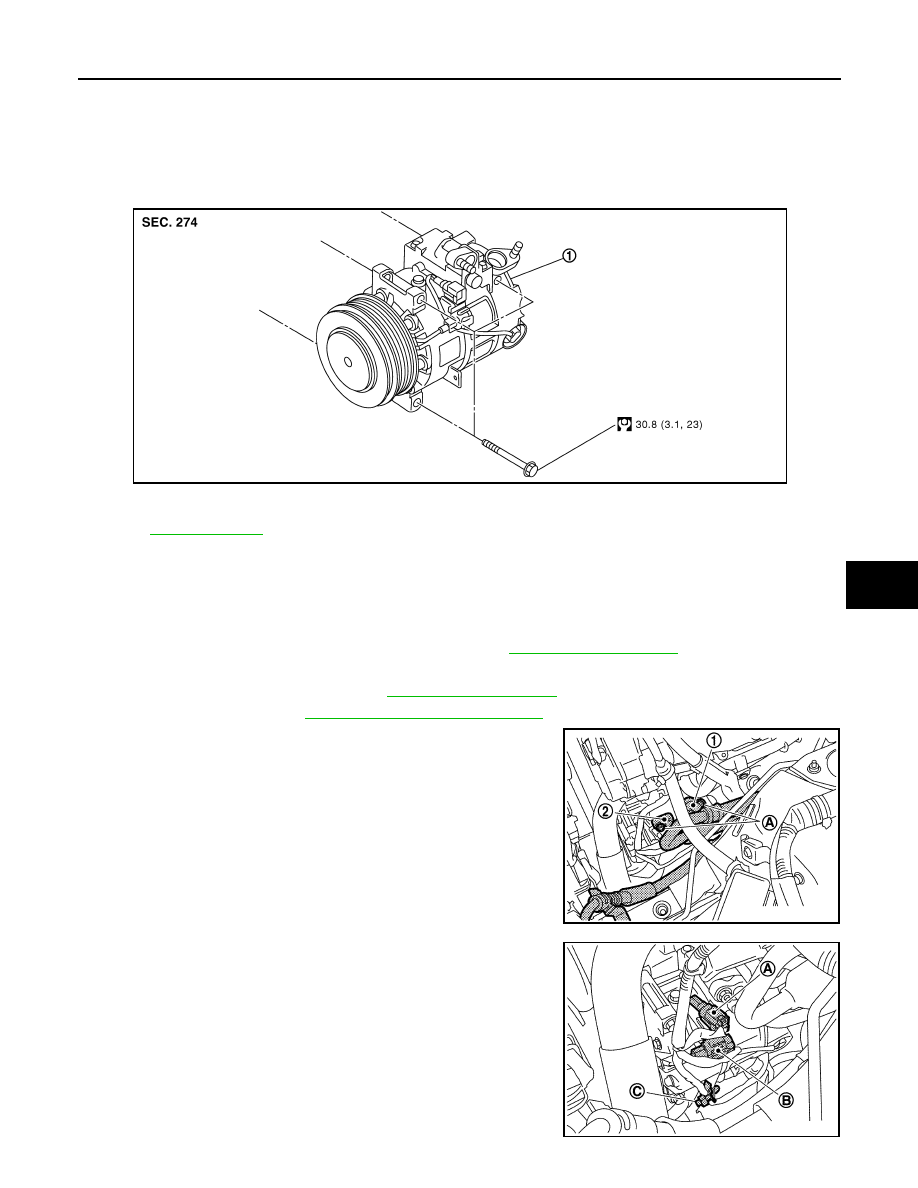

COMPRESSOR

Exploded View

INFOID:0000000003545476

Removal and Installation

INFOID:0000000003545477

REMOVAL

1.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2.

Remove air cleaner case (LH) and air duct (LH). Refer to

.

3.

Remove engine undercover, using power tools.

4.

Remove cooling fan assembly. Refer to

5.

Remove drive belt. Refer to

EM-13, "Removal and Installation"

.

6.

Remove mounting nuts (A) from low-pressure flexible hose (1)

and high-pressure flexible hose (2).

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

7.

Disconnect compressor (ECV) connector (A).

8.

Disconnect compressor (magnet clutch) connector (B).

9.

Remove harness clip (C)

1.

Compressor

Refer to

JSIIA0011GB

JPIIA0685ZZ

JPIIA0686ZZ