Infiniti EX35. Manual - part 639

EC-298

< COMPONENT DIAGNOSIS >

[VQ35HR]

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

7.

Check 1st trip DTC.

With GST

1.

Start engine and warm it up to normal operating temperature.

2.

Set voltmeter probes to ECM harness connector terminals under the following conditions.

3.

Check that the voltage is less than 4.2 V.

4.

Turn ignition switch OFF and wait at least 10 seconds.

5.

Start engine and wait at least 20 seconds.

6.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000003133450

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection M95. Refer to Ground Inspection in

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK CONNECTOR

1.

Disconnect EVAP control system pressure sensor harness connector.

2.

Check sensor harness connector for water.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace harness connector.

3.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT-I

1.

Turn ignition switch ON.

2.

Check the voltage between EVAP control system pressure sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 4.

4.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between EVAP control system pressure sensor harness connector and ECM har-

ness connector.

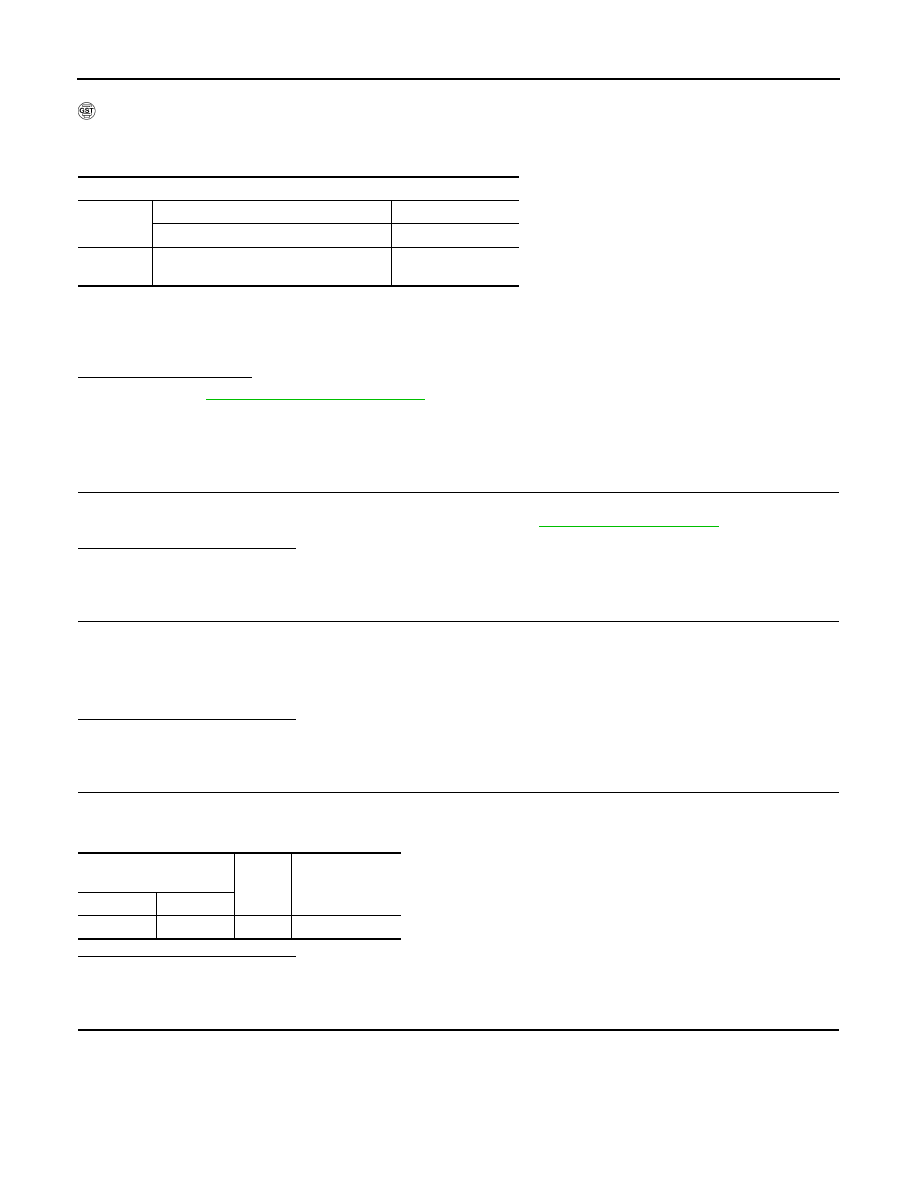

ECM

Connector

+

–

Terminal

Terminal

M107

106

(Fuel tank temperature sensor signal)

128

Water should not exist.

EVAP control system

pressure sensor

Ground

Voltage (V)

Connector

Terminal

B252

3

Ground

Approx. 5