Infiniti EX35. Manual - part 534

DLN-86

< SYMPTOM DIAGNOSIS >

[REAR PROPELLER SHAFT: 3F80A-1VL107]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

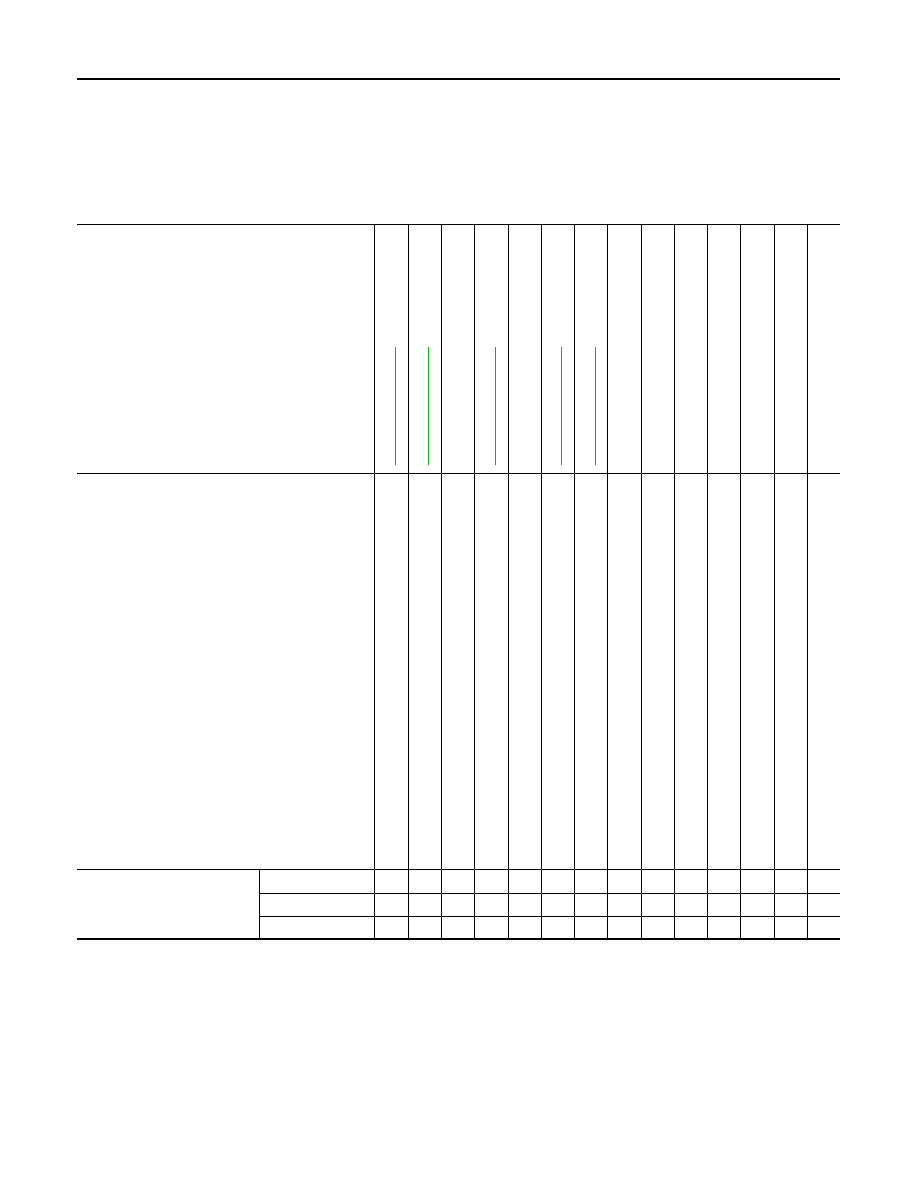

NVH Troubleshooting Chart

INFOID:0000000003135767

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference

—

—

NV

H

in

D

L

N

s

e

c

ti

on.

N

V

H

in F

A

X

, RAX,

FSU and RSU section.

NV

H

in

WT s

e

cti

on

.

NV

H

in

WT s

e

cti

on

.

NV

H

in

R

A

X

s

e

c

tio

n.

NV

H

in

B

R

s

ec

tio

n.

NV

H

in

S

T

s

e

c

ti

o

n

.

Possible cause and SUSPECTED PARTS

Un

ev

en

rot

a

ti

ng

to

rqu

e

Cen

ter be

ari

n

g i

mpro

p

e

r in

st

a

lla

ti

on

Exce

ss

iv

e c

en

te

r be

ari

ng

ax

ia

l e

nd

pl

ay

Cen

ter be

ari

n

g mo

un

ti

n

g

(i

ns

ul

at

o

r)

c

rac

ks

, d

a

m

a

g

e

or d

e

te

rio

rat

io

n

Exce

ss

iv

e j

o

in

t a

n

g

le

Rot

a

ti

on

im

ba

lan

c

e

Exce

ss

iv

e ru

no

ut

DIF

F

ERENTI

AL

AX

LE A

N

D

SUSPENSION

TI

RE

ROAD W

H

EEL

DRIV

E SHAFT

BRA

K

E

ST

EERING

Symptom

Noise

×

×

×

×

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

×

×

×

×