Infiniti EX35. Manual - part 358

BRM-34

< REMOVAL AND INSTALLATION >

REPAIRING HIGH STRENGTH STEEL

REPAIRING HIGH STRENGTH STEEL

High Strength Steel (HSS)

INFOID:0000000003134503

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

Read the following precautions when repairing HSS:

1.

Additional points to consider

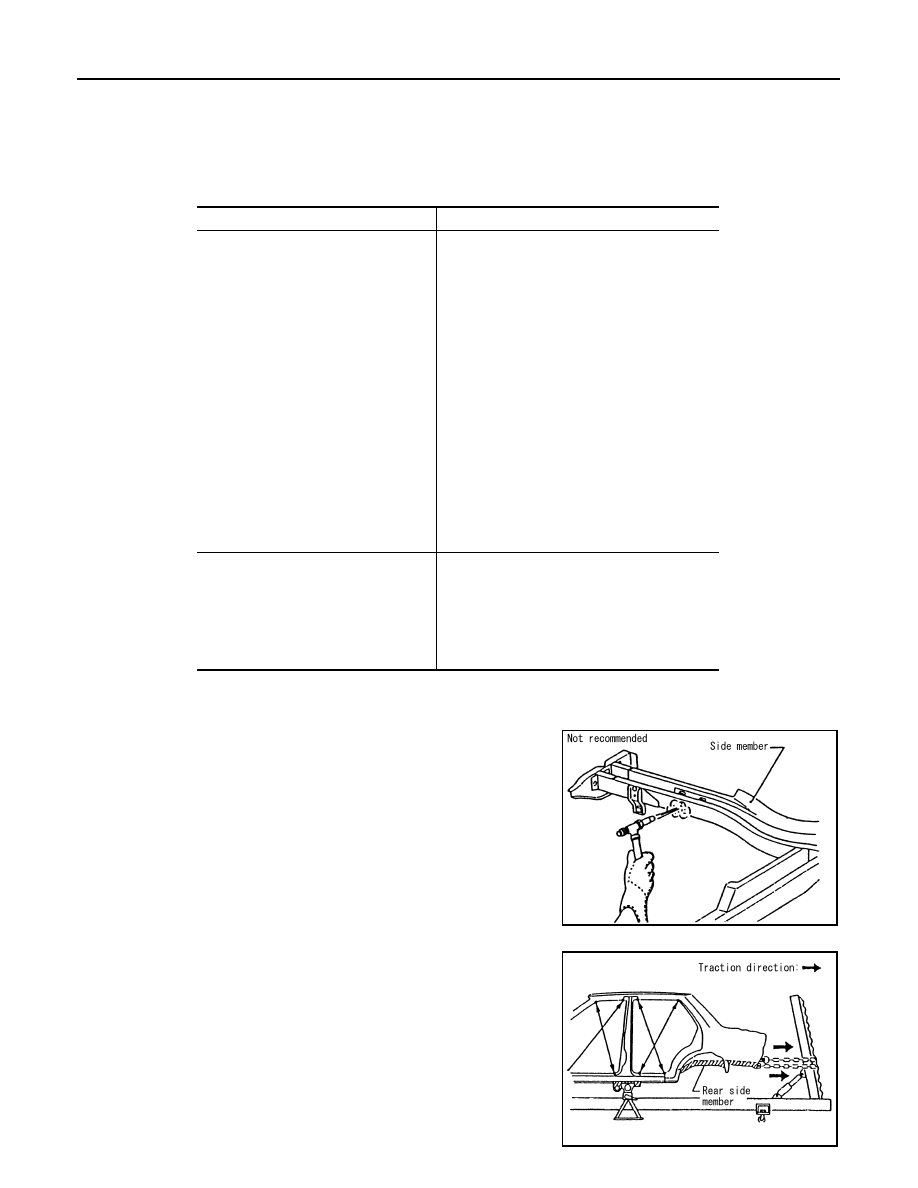

• The repair of reinforcements (such as side members) by heat-

ing is not recommended since it may weaken the component.

When heating is unavoidable, do not heat HSS parts above

550

°

C (1,022

°

F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropri-

ate.)

• When straightening body panels, use caution in pulling any

HSS panel. Because HSS is very strong, pulling may cause

deformation in adjacent portions of the body. In this case,

increase the number of measuring points, and carefully pull

the HSS panel.

Tensile strength

Major applicable parts

370 - 590 MPa

• Front strut housing

• Hoodledge reinforcement

• Upper front hoodledge

• Lower dash

• Lower dash crossmember assembly

• Front roof rail

• Upper inner front pillar assembly

• Inner center pillar

• Inner sill

• Upper & lower outer rear wheelhouse exten-

sion

• Center front floor

• Front floor

(Component part)

• Front & rear side member assembly

• Front side member closing plate assembly

• Front side member outrigger assembly

• Front side member rear extension

• Rear seat crossmember

• Other reinforcements

780 - 1350 MPa

• Center pillar reinforcement

(Component part)

• Inner center pillar

(Component part)

• Outer side roof rail reinforcement

• Outer sill reinforcement

(Component part)

PIIA0115E

PIIA0116E