Content .. 1442 1443 1444 1445 ..

Infiniti EX35. Manual - part 1444

TM-164

< ON-VEHICLE REPAIR >

[5AT: RE5R05A]

CONTROL VALVE WITH TCM

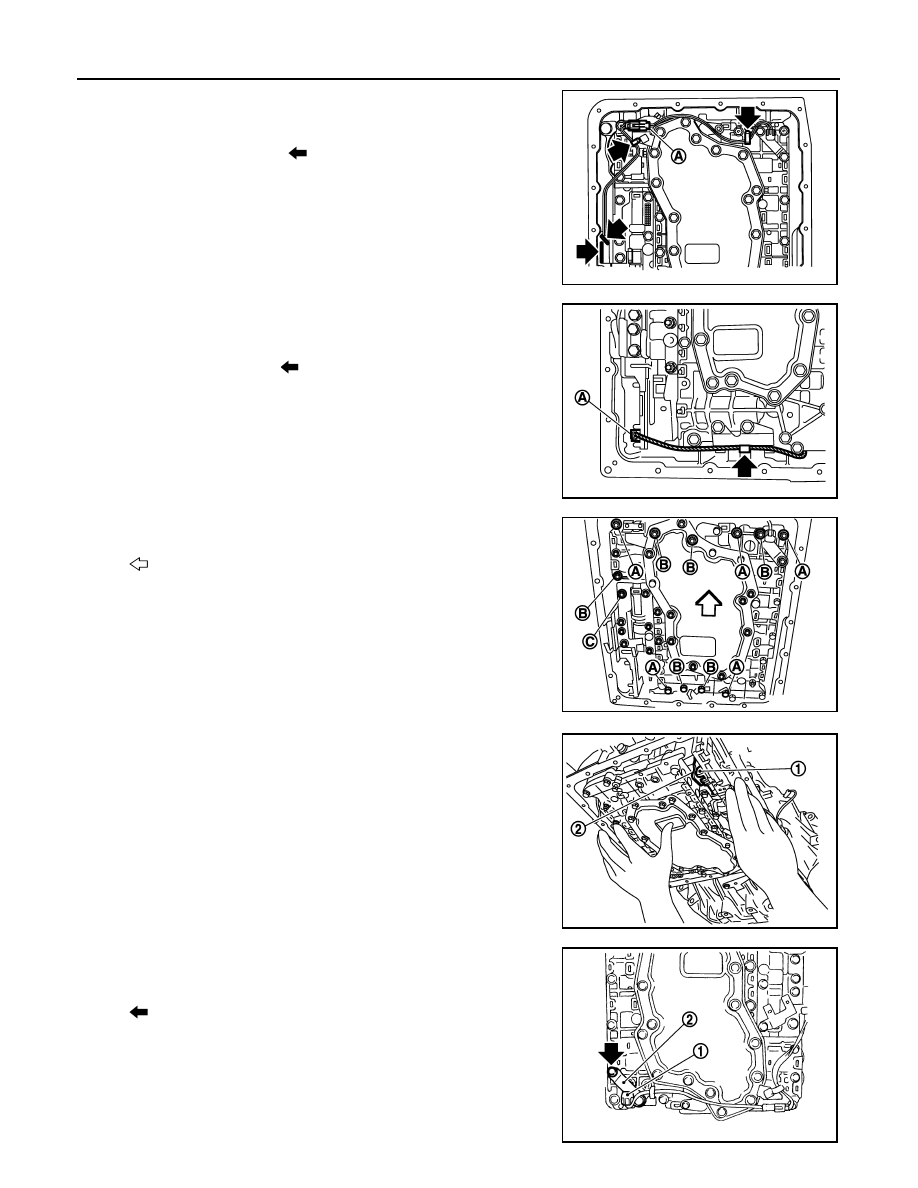

13. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Be careful not to damage connector.

14. Disengage terminal clips (

).

15. Disconnect revolution sensor connector (A).

CAUTION:

Be careful not to damage connector.

16. Disengage terminal clip (

).

17. Remove bolts (A), (B) and (C) from control valve with TCM.

18. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve (1) notch

and manual plate (2) height. Remove it vertically.

19. Remove A/T fluid temperature sensor 2 (1) with bracket (2) from

control valve with TCM.

SCIA8124E

JPDIA0011ZZ

: Vehicle front

SCIA8074E

JPDIA0012ZZ

: Bolt

JPDIA0013ZZ