Content .. 1216 1217 1218 1219 ..

Infiniti EX35. Manual - part 1218

RAX-12

< ON-VEHICLE REPAIR >

REAR DRIVE SHAFT

Use paint or similar substance for matching marks. Never scratch the surface.

5.

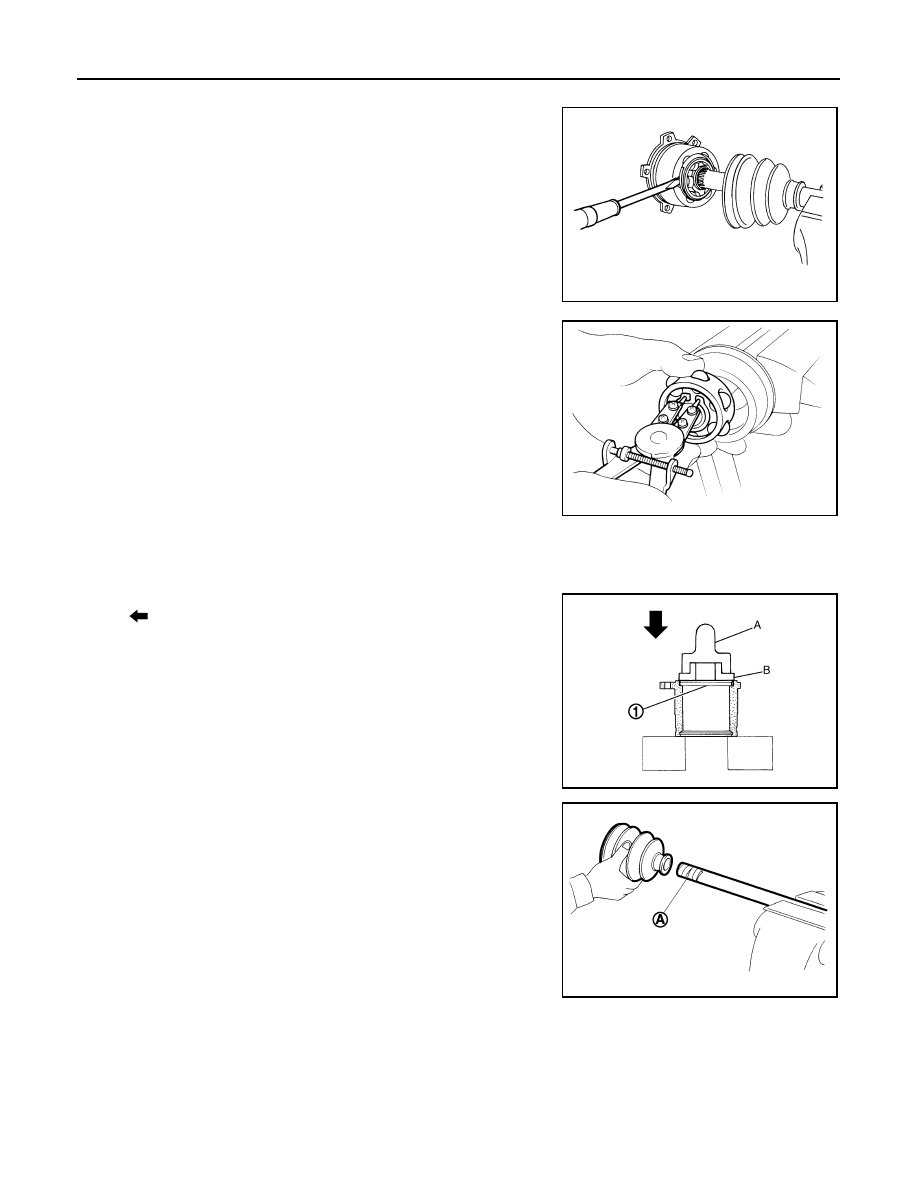

Remove stopper ring with suitable tool, and pull out housing.

6.

Put matching marks on ball cage/steel ball/inner race assembly

and shaft.

CAUTION:

Use paint or similar substance for matching marks. Never

scratch the surface.

7.

Remove snap ring, then remove ball cage/steel ball/inner race

assembly from shaft.

8.

Remove boot from shaft.

ASSEMBLY

1.

Remove old grease on housing with paper waste.

2.

If plug (1) has been removed, use a drift to press in a new one.

3.

Wrap serration shaft with tape (A) to protect the boot from dam-

age. Install boot and boot bands to shaft.

CAUTION:

Never reuse boot and boot band.

4.

Remove the tape wrapped around the serrated on shaft.

SRA249A

SFA514A

: Press

A

: Drift [SST: KV38100500 (

−

)]

B

: Drift [SST: KV38102200 (

−

)]

JPDIF0016ZZ

JPDIF0009ZZ