Content .. 1189 1190 1191 1192 ..

Infiniti EX35. Manual - part 1191

PWC-28

< COMPONENT DIAGNOSIS >

ENCODER CIRCUIT

ENCODER CIRCUIT

DRIVER SIDE

DRIVER SIDE : Description

INFOID:0000000003573491

Detects condition of the front power window motor (driver side) operation and transmits to power window main

switch as pulse signal.

DRIVER SIDE : Component Function Check

INFOID:0000000003573492

1.

CHECK ENCODER OPERATION

Check front driver side door glass perform AUTO open/close operation normally with power window main

switch.

Is the inspection result normal?

YES

>> Encoder operation is OK.

NO

>> Refer to

PWC-28, "DRIVER SIDE : Diagnosis Procedure"

DRIVER SIDE : Diagnosis Procedure

INFOID:0000000003573493

Encoder Circuit Check

1.

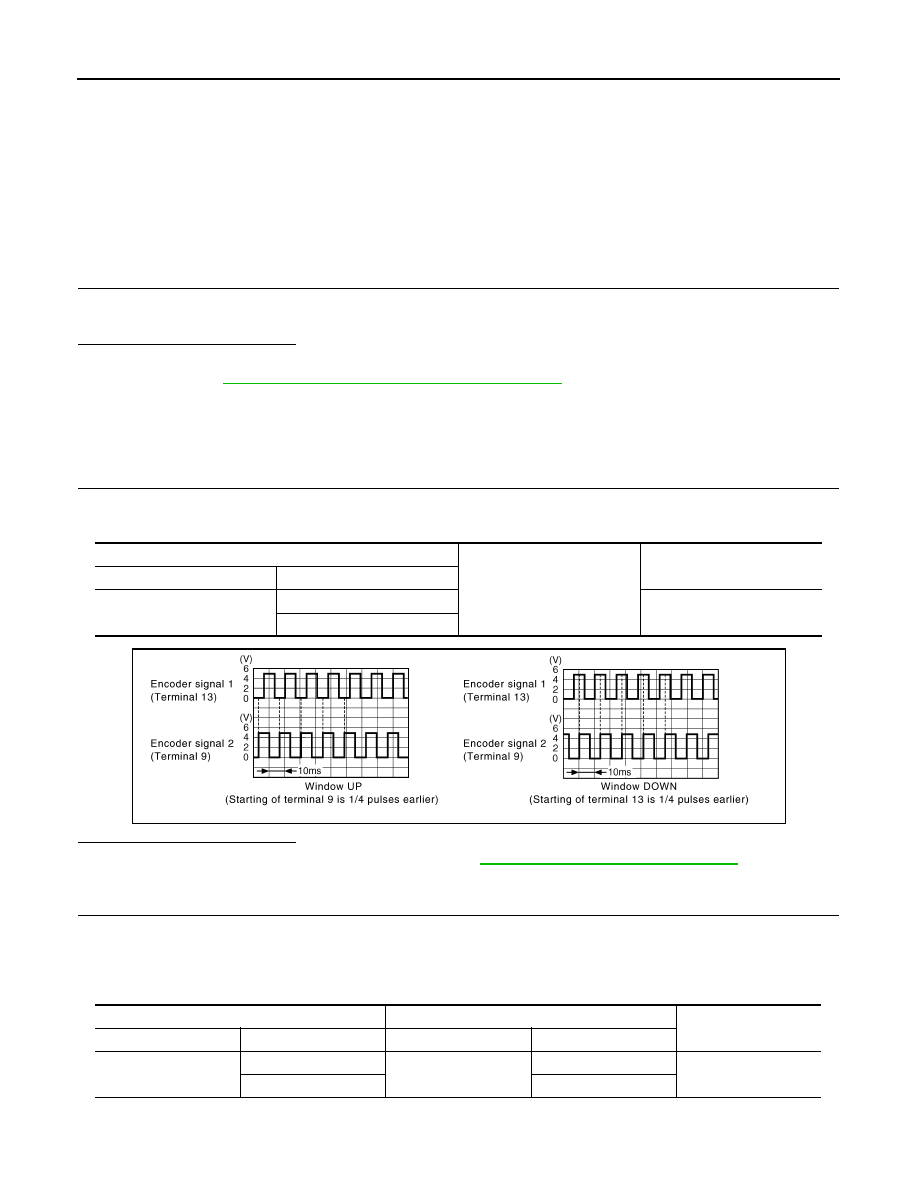

CHECK ENCODER SIGNAL

1.

Turn ignition switch ON.

2.

Check signal between power window main switch harness connector and ground with oscilloscope.

Is the inspection result normal?

YES

>> Replace power window main switch. Refer to

PWC-112, "Removal and Installation"

.

NO

>> GO TO 2.

2.

CHECK ENCODER SIGNAL CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect power window main switch connector and front power window motor (driver side) connector.

3.

Check continuity between power window main switch harness connector and front power window motor

(driver side) harness connector.

4.

Check continuity between power window main switch harness connector and ground.

Power window main switch

Ground

Signal

(Reference value)

Connector

Terminal

D8

9

Refer to following signal

13

JMKIA0220GB

Power window main switch

Front power window motor (driver side)

Continuity

Connector

Terminal

Connector

Terminal

D8

9

D10

3

Existed

13

5