Content .. 1186 1187 1188 1189 ..

Infiniti EX35. Manual - part 1188

PWC-16

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

4.

Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES

BCS-84, "Removal and Installation"

NO

>> Repair or replace harness.

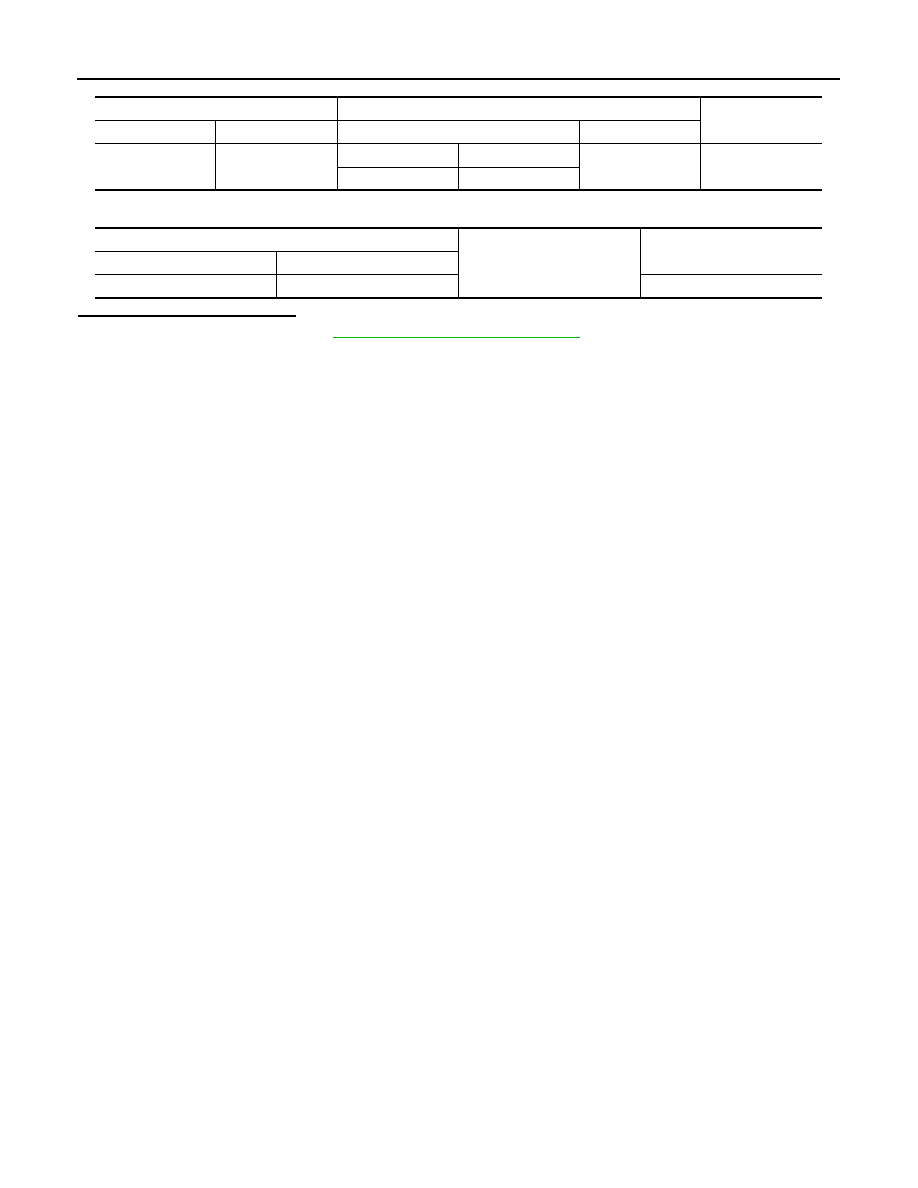

BCM

Rear power window switch

Continuity

Connector

Terminal

Connector

Terminal

M118

3

LH

D54

1

Existed

RH

D74

BCM

Ground

Continuity

Connector

Terminal

M118

3

Not existed