Hyundai Matrix (2007 year). Instruction - part 28

OWNER MAINTENANCE

6

ELECTRIC COOLING FANS

POWER STEERING FLUID

31

LEVEL

SG220A1-E

SG230A1-E

To check the power steering fluid level,

Petrol engine

be sure the ignition is "OFF", then

!

check to make certain that the power

WARNING:

steering fluid level is between the

The cooling fan is controlled by

"MAX" and "MIN" level markings on

engine coolant temperature and may

the fluid reservoir.

sometimes operate even when the

engine is not running. Use extreme

NOTE:

caution when working near the

Grinding noise from power steering

blades of the cooling fan so that

pump may be heard immediately

you are not injured by a rotating fan

after the engine is started in ex-

blade. As the engine coolant tem-

tremely

cold

condition

perature decreases, the fan will au-

HFC5004

(below -4°F). If the noise stops dur-

tomatically shut off. This is a nor-

Diesel engine

ing warm up, there is no abnormal

mal condition.

function in the system. This is due

to a power steering fluid character-

The engine cooling fan should operate

istic in extremely cold conditions.

before the temperature gauge reaches

the upper portion of the scale and the

FLUID RECOMMENDATION

condenser fan should operate when-

Only automatic transmission fluid

ever the air conditioning is in use.

meeting the specification of PSF-3 or

Dexron 2 should be used in the power

steering system.

G230A02FC

The power steering fluid level should

be checked daily.

fcuk-6.p65

31

12/27/2006, 10:16 AM

6 OWNER MAINTENANCE

32

BLEEDING THE FUEL

SYSTEM

SG230B1-E

G350B01FC-EAT

Air pipe

POWER STEERING HOSES

(Diesel engine)

Power steering hoses should be

checked for damage, deterioration and

leakage at each service.

G350B01FC

2. Pump the hand pump until there are

G350A01FC

no more bubbles in the fuel coming

out of the air pipe. When doing this,

The fuel system should be bled to

place a cloth around the air pipe to

remove air as described in the illustra-

prevent the escaping fuel from spew-

tion if the fuel supply is exhausted

ing about.

during travel, when the fuel filter is

3. Replace the air cap when there are

replaced, or if the vehicle is not used

no more bubbles in the fuel.

for a long time.

4. Continue pumping until the hand

1. Remove the air cap with pushing

pump becomes stiff.

the button.

5. Finally, check to be sure that there

is no leakage of fuel.

If in doubt, consult your nearest

Hyundai authorised repairer.

fcuk-6.p65

32

12/27/2006, 10:16 AM

OWNER MAINTENANCE

6

REMOVAL OF WATER FROM

33

THE FUEL FILTER

G300A02B-EAT

(Diesel engine)

!

WARNING:

o Do not smoke or have any other

open flame near the vehicle whilst

bleeding the fuel system.

o Be sure to carefully wipe away

any water drained out in this

manner, because the fuel mixed

in the water might be ignited and

result in a fire.

G300B02FC

1. Loosen the drain plug at the bottom

G300A02FC

of the fuel filter.

If the fuel filter warning lamp illumi-

2. Tighten the drain plug when water

nates during driving, it indicates that

no longer comes out.

water has accumulated in the fuel

3. Check to be sure that the warning

filter. If this occurs, remove the water

lamp illuminates when the ignition

as described.

key is turned to "ON", and that it

goes off when the engine is started.

If in doubt, consult your nearest

Hyundai authorised repairer.

NOTE:

It is recommended that water accu-

mulated in the fuel filter should be

removed by an authorised Hyundai

authorised repairer.

fcuk-6.p65

33

12/27/2006, 10:16 AM

6 OWNER MAINTENANCE

HEADLIGHT AIMING

34

ADJUSTMENT

G290A01FC-EAT

Vertical Aiming

Before performing aiming adjustment,

Horizontal Aiming

! WARNING:

make sure of the following.

o Do not smoke or have any other

open flame near the vehicle whilst

1. Keep all tyres inflated to the correct

bleeding the fuel system.

pressure.

o Be sure to carefully wipe away

2. Place the vehicle on level ground

any water drained out in this

and press the front bumper & rear

manner, because the fuel mixed

bumper down several times. Place

in the water might be ignited and

the vehicle at a distance of 118 in.

result in a fire.

(3,000 mm) from the test wall.

G290A01FC

3. See that the vehicle is unloaded

Extracting air in the fuel filter

(except for full levels of coolant,

5. Open the bonnet.

If you drove until you have no fuel left

engine oil and fuel, and spare tyre,

6. Draw the vertical line (through the

or if you replaced the fuel filter, be sure

jack, and tools).

centre of each headlight beam pat-

to extract air in the fuel system as it

4. Clean the head lights lens and turn

tern) and the horizontal line (through

makes you difficult to start the engine.

on the headlight (Low beam).

the centre of each headlight beam

1) Remove the air extract nozzle cap

pattern) on the aiming screen.

on the fuel filter.

And then, draw the horizontal paral-

2) Pump up and down until the fuel

lel line at 1.18 in. (30 mm) under the

flows out of the plug opening.

horizontal line.

7. Adjust each cut-off line of the low

beam to the parallel line with a phillips

NOTE:

screwdriver - VERTICAL AIMING

Use cloths when you extract air so

8. Adjust each cut-off line of the low

that the fuel is not sprayed around.

beam to each vertical line with a

Clean the fuel around the fuel filter

phillips screwdriver - HORIZONTAL

or the injection pump before start-

AIMING.

ing the engine to prevent fire. Fi-

nally, check each part if the fuel is

leaking.

fcuk-6.p65

34

12/27/2006, 10:16 AM

OWNER MAINTENANCE

6

REPLACING LIGHT BULBS

35

G290B02FC-EAT

SG250A2-E

Specifications:

Adjustment After Headlight As-

In the event of bulb failure being expe-

sembly Replacement

"H"

rienced, ensure that the relative light-

Vertical line

Horizontal centre line of headlights

ing circuit is turned off prior to attempt-

from ground.

ing to replace the bulb. The illustra-

30mm

Horizontal line

W

: 26.5 in.(675 mm)

(1.18 in.)

tions on the following page will assist

"P"

in locating and removing the various

"W"

bulbs. Ensure that the replacement

Distance between each headlight cen-

bulb has the same cap configuration

H

Cut-off line

tre.

and wattage as the original.

: 46.3 in. (1,177 mm)

See page

6-37 for the wattage

L

Ground

descriptions.

line

"L"

H

Distance between the headlights and

G290B01L-D

the wall that the lights are tested

!

CAUTION:

against.

If the vehicle has had front body repair

Keep the lamps out of contact with

: 118 in. (3,000 mm).

and the headlight assembly has been

petroleum products, such as oil,

replaced, the headlight aiming should

petrol, etc.

be checked using the aiming screen

as shown in the illustration. Turn on

the headlight switch. (Low Beam Posi-

tion)

1. Adjust headlights so that main axis

of light is parallel to the centre line

of the body and is aligned with point

"P" shown in the illustration.

2. Dotted lines in the illustration show

the centre of the headlights.

fcuk-6.p65

35

12/27/2006, 10:16 AM

6 OWNER MAINTENANCE

36

G270A02A-GAT

HEADLIGHT BULB

!

Replacement instructions:

WARNING

The halogen bulb contains gas un-

der pressure and if impacted could

shatter, resulting in flying fragments.

Always wear eye protection when

servicing the bulb. Protect the bulb

against abrasions or scratches and

against liquids when lighted. Turn

on the bulb only when installed in a

G270A02FC

headlight. Replace the headlight if

5. Push the bulb spring for removing

damaged or cracked. Keep the bulb

the headlight bulb.

out of the reach of children and

G270A01FC

6. Remove the protective cap from the

dispose of the used bulb with care.

1. Allow the bulb to cool. Wear eye

replacement bulb and install the

protection.

new bulb by matching the plastic

2. Always grasp the bulb by its plastic

base with the headlight hole. Install

base, avoid touching the glass.

the dust cover after retightening the

3. Disconnect the power cord from the

bulb spring and reconnect the power

bulb base in the back of the head-

cord.

light.

7. Use the protective cap and carton

4. Remove the dust cover.

to dispose of the old bulb.

8. Check for proper headlight aim.

fcuk-6.p65

36

12/27/2006, 10:16 AM

OWNER MAINTENANCE

6

BULB WATTAGE

37

G280A02FC-EAT

G280A02FC-D

No.

Part Name

Wattage

Socket type

No.

Part Name

Wattage

Socket type

1

Front Position Light

5

W2.1×9.5D

8

High Mounted Rear Stop Light

21

BA 15s

2

Head Light (High/Low)

60/55

P43t-38

9

Rear Fog Light

21

BA 15s

3

Front Fog Light (Not all models)

55

PK22s

10

License Plate Light

5

W2.1×9.5D

4

Front Turn Signal Light

21

BA 15s

11

Luggage Compartment Light

5

S8.5/8.5

Interior

Map Light

5

W2.1×9.5D

12

Rear

Turn Signal Light

21

BA 15s

5

Light

Room Light

10

S8.5/8.5

Combination

Stop/Tail Light

21/5

BAY 15d

6

Side Repeater

10

W2.1×9.5D

Light

Back -up Light

21

BA 15s

7

Front Door Edge Warning Light (Not all models)

5

W2.1×4.6D

fcuk-6.p65

37

12/27/2006, 10:16 AM

6 OWNER MAINTENANCE

FUSE PANEL DESCRIPTION

38

G200C03FC-EAT

Engine Compartment

DESCRIPTION

FUSE RATING

PROTECTED COMPONENTS

(Petrol Engine)

ALT

120A

Generator

B+

40A

(A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse

ECU

30A

Generator, Engine control relay, ECM

RAD

20A

Radiator fan relay

IGN

40A

Start relay, Ignition switch

BLR

40A

Blower relay

P/WIN

30A

Power window relay

COND

20A

Condenser fan relay #1

ABS

40A

ABS control module, ABS bleeding connector, ESP

ABS

40A

ABS control module, ABS bleeding connector, ESP

F/PUMP

10A

Fuel pump relay

INJ

15A

Injector, lgnition coil

MAP sensor, Oxygen sensor, CP sensor,

SNSR

10A

Knock sensor, Throttle position sensor

Audio, Room lamp, Overhead console lamp,

ROOM LP

10A

lnstrument cluster

DRL

15A

DRL control module

HORN

10A

Horn relay

A/CON

10A

A/C relay

FR FOG

15A

Front fog lamp relay

ECU

10A

ECM, TCM

LP

20A

Tail lamp relay

Left rear combi lamp, Left position lamp,

TAIL LH

10A

Left License lamp

Right rear combi lamp, Right position lamp,

TAIL RH

10A

G200C03FC

Right License lamp

H/LP LH

15A

Left head lamp

H/LP RH

15A

Right head lamp, (H/LP IND) Fuse

NOTE:

Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing.

When you inspect the fuse box on your vehicle, refer to the fuse box label.

fcuk-6.p65

38

12/27/2006, 10:16 AM

OWNER MAINTENANCE

6

39

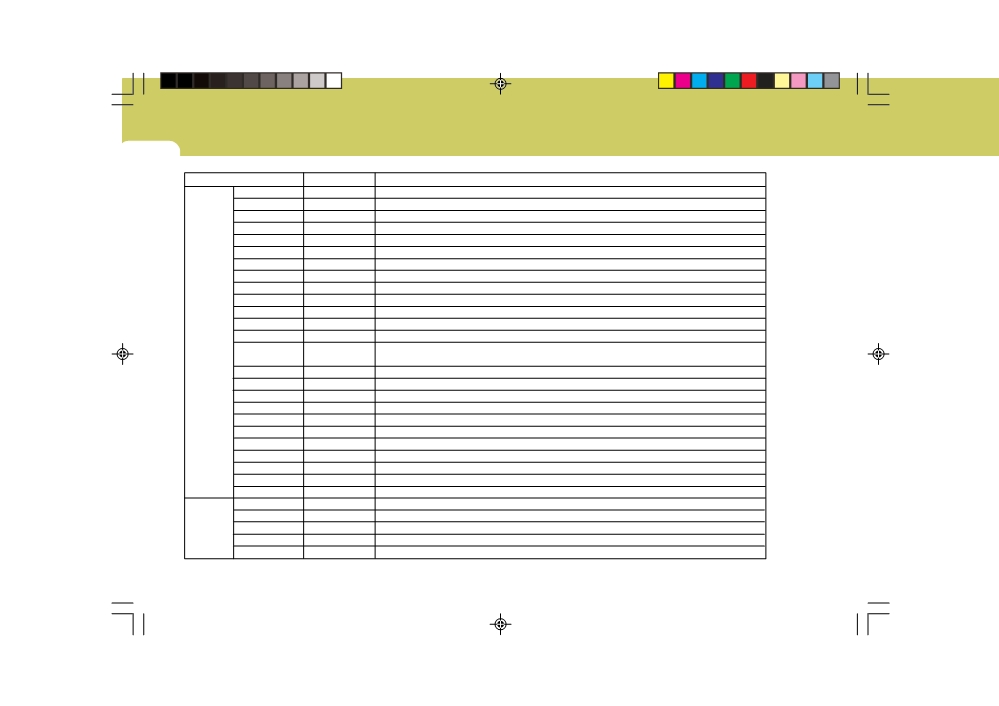

G200E03FC-GAT

(Diesel Engine)

G200E03FC

NOTE:

Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing.

When you inspect the fuse box on your vehicle, refer to the fuse box label.

fcuk-6.p65

39

12/27/2006, 10:16 AM

6 OWNER MAINTENANCE

40

DESCRIPTION

FUSE RATING

PROTECTED COMPONENTS

ALT

140A

Generator

B+

40A

(A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse, Deicer

ECU

30A

Generator, Engine control relay, ECM

RAD

30A

Radiator fan relay

IGN

40A

Start relay, Ignition switch

BLR

40A

Blower relay

P/WIN

30A

Power window relay

COND

30A

Condenser fan relay #1

ABS

40A

ABS control module, ABS bleeding connector, ESP

ABS

40A

ABS control module, ABS bleeding connector, ESP

F/PUMP

10A

Fuel pump relay

FUSE

ECU

30A

ECM No.5 (Batt+)

ECU

10A

ECM No.4 (Batt+), Stop lamp switch, PTC heater relay #1

Glow plug relay, Assistor heater relay 1/2, Stop lamp switch,

SNSR

15A

TDC sensor, EGR act, Throttle plate act, VGT vacuum

ROOM LP

10A

Audio, Room lamp, Overhead console lamp, lnstrument cluster, ETACM, Luggage lamp

DRL

15A

DRL control module

HORN

10A

Horn relay

A/CON

10A

A/C relay

FR FOG

15A

Front fog lamp relay

ECU

10A

ECM, TCM

LP

20A

Tail lamp relay

TAIL LH

10A

Left rear combi lamp, Left position lamp, Left License lamp

TAIL RH

10A

Right rear combi lamp, Right position lamp, Right License lamp

H/LP LH

15A

Left head lamp

H/LP RH

15A

Right head lamp, (H/LP IND) Fuse

PTC HTR 1

40A

PTC heater relay #1

GLOW

80A

GLOW relay

FUSIBLE

PTC HTR 2

40A

PTC heater relay #2

FFHS

30A

FFHS relay

PTC HTR 3

40A

PTC heater relay #3

fcuk-6.p65

40

12/27/2006, 10:16 AM

OWNER MAINTENANCE

6

41

G200D01FC-GAT

Inner Panel

DESCRIPTION

FUSE RATING

PROTECTED COMPONENTS

H/LP IND

10A

Head lamp indicator

Defogger relay, Left(Right) outside mirror motor,

HTD IND

10A

Rear window motor

A/CON

10A

A/C Switch

RR HTD

30A

Defogger relay

STOP

10A

Stop lamp switch, Power window relay

D/LOCK

15A

Door lock(unlock) relay, ETACM, Sunroof relay

HAZARD

10A

Burglar alarm relay, Hazard relay

AUDIO

10A

Audio

C/LIGHT

15A

Cigarette lighter

A/B

10A

SRS control module

A/B IND

10A

SRS IND.

Hazard switch, Seat belt timer, Instrument cluster,

T/SIG

10A

ABS control module, Pre-excitation resistor, Washer motor

ECU

15A

ECM, Vehicle speed sensor, TCM, Ignition coil

ETACS

10A

ETACM, A/T Shift lever

RR WPR

10A

Rear wiper motor, Rear wiper relay

START

10A

Start relay

FRT WPR

20A

Wiper relay, Washer motor, Wiper & Defogger timer

S/HTD

15A

Left (Right) front seat warmer switch

P/OUTLET

25A

Front (Rear) power outlet

ETACM, Power window relay, Defogger relay, Sunroof relay

IG2

10A

Head lamp relay, Blower relay

O/S MRR

10A

Outside mirror switch, Rear fog lamp relay

G200D01FC

fcuk-6.p65

41

12/27/2006, 10:16 AM

EMISSION CONTROL SYSTEM

Emission Control System

7-2

Catalytic Converter

7-3

EGR System

7-4

7

7

fcuk-7.p65

1

12/27/2006, 10:17 AM

EMISSION CONTROL SYSTEMS

7

EMISSION CONTROL SYSTEMS

2

SH010A1-E

SH010B1-E

When the engine is started, the vapours

(Not all models)

1. Crankcase Emission Control

stored in the canister are drawn into

System

the induction system through the purge

Depending upon the market for which

control solenoid valve and are subse-

the vehicle is destined, the emission

The positive crankcase ventilation

quently burned.

control system will comprise one or

system is employed to prevent air

The purge control solenoid valve is

more of the following emission control

pollution caused by blow-by gases

controlled by the ECU; when the en-

devices.

being emitted from the crankcase by

gine coolant temperature is low or the

introducing fresh air to the crankcase

engine is idling, the purge control valve

(1) Crankcase emission control sys-

through the air cleaner where this mixes

is closed and fuel vapours remain

tem

with blow-by gases and then passes

stored in the canister. Under normal

(2) Evaporative emission control sys-

through the PCV valve into the intake

running conditions when the engine is

tem

manifold from where it subsequently

warm, the valve opens and the vapours

(3) Exhaust emission control system

enters the combustion chamber and is

are drawn into the inlet tract and sub-

burned.

sequently burned in the combustion

In order that the proper functioning of

chamber.

the emission control systems may be

ensured, it is recommended that the

vehicle is inspected and maintained

SH010C1-E

SH010D1-E

by an Hyundai authorised repairer in

2. Evaporative Emission Control

3. Exhaust Emission Con Trol

accordance with the maintenance

System

System

schedule in this manual.

The Evaporative Emission Control Sys-

The exhaust emission control system

tem is designed to prevent fuel vapours

is a highly effective system which

from escaping into the atmosphere

controls exhaust emission whilst main-

through the fuel tank ventilation sys-

taining good vehicle performance.

tem.

Whilst the engine is not running, fuel

vapours generated inside the fuel tank

are absorbed and stored in a charcoal

canister.

fcuk-7.p65

2

12/27/2006, 10:17 AM

EMISSION CONTROL SYSTEMS

7

CATALYTIC CONVERTER

3

SH020A1-E

It is of the utmost importance that the

For these reasons, it is advisable that

Catalytic Convertor Operation

following information is read and un-

the exhaust gas emission be tested at

Precautions

derstood by the vehicle operator in

each routine service with a gas ana-

; For a petrol engine

order to prevent operational problems

lyzer having a Hydrocarbon measuring

arising from damage to the catalyst.

facility to ensure continued reliability

Damage to the catalyst will result if

of the catalyst.

contamination occurs through the use

Push or tow starting of the vehicle is to

of leaded fuel. Whilst the vehicle is

be avoided since unburnt fuel may

fitted with a reduced diameter filler

enter the catalyst and result in dam-

neck to prevent charging of the fuel

age. (Note, it is impossible to push or

tank with a leaded fuel pump nozzle, it

tow start a Hyundai model equipped

is possible that the use of funnels or

with fuel injection since the fuel pump

fuel cans will permit leaded fuel to be

safety interlock will prevent the pump

introduced into the fuel tank.

from operating under these conditions).

The catalyst is intolerant of unburnt

Operation of the catalyst involves ex-

Catalytic Converter

HFC505

fuel and therefore if an engine misfire

tremely high temperatures being at-

condition exists, damage to the cata-

tained within the catalytic convertor,

Hyundai Matrix models are fitted with

lyst will occur. It is imperative that if

and although the convertor is fitted

catalytic convertors which require spe-

a misfire condition develops, the ve-

with heat shields, it is important that

cial operating considerations. The cata-

hicle is immediately presented to a

the vehicle is not parked over combus-

lytic convertor serves to oxidize cer-

Hyundai authorised repairer for rectifi-

tible or volatile material which may

tain noxious elements of the exhaust

cation. Similarly, the practice of cer-

result in fire.

gases leaving the engine to reduce the

tain ignition system diagnosis proce-

If the above precautions are not ad-

level of pollutants emitted from the

dures which involve inducing a misfire

hered to and the catalyst becomes

vehicle and, provided that care is ex-

(cylinder power balance tests for ex-

inoperative, the resultant increase in

ercised to prevent damage, the cata-

ample) may result in catalyst damage.

core temperature will result in a "melt

lyst will operate efficiently for the life

down" where the catalyst core will melt

of the vehicle.

and subsequently may block the ex-

haust system.

fcuk-7.p65

3

12/27/2006, 10:17 AM

7 EMISSION CONTROL SYSTEMS

EGR SYSTEM

4

Due to the fragile nature of the catalyst

H020C01S-GAT

element, it is important that damage

; For a diesel engine

does not occur when the vehicle is

This system helps control oxides of

raised by means of a garage jack.

nitrogen by recirculating a part of the

Care must also be exercised to avoid

exhaust gas into the engine.

driving over road hazards or debris

which may cause damage to the cata-

lyst element.

H020D01S-GAT

; For a diesel engine

All Hyundai vehicles are equipped with

oxidation type catalytic converter to

reduce the carbon monoxide, hydro-

carbons and particulate contained in

the exhaust gas.

fcuk-7.p65

4

12/27/2006, 10:17 AM

CONSUMER INFORMATION

Vehicle Identification Number (VIN)

8-2

Engine Number

8-2

Tyre Pressures

8-3

Snow Tyres

8-3

Tyre Chains

8-3

Tyre Rotation

8-4

Tyre Balancing

8-4

Tyre Replacement

8-5

Wheel Replacement

8-5

Spare Tyre and Tools

8-6

8

8

fcuk-8.p65

1

12/27/2006, 10:17 AM

8 CONSUMER INFORMATION

VEHICLE IDENTIFICATION

2

NUMBER (VIN)

I010A01FC-EAT

The vehicle identification number (VIN)

Petrol engine (1.8 DOHC)

is unique to each individual vehicle

and is the number (sometimes referred

to as chassis number) used upon the

vehicle registration document to iden-

tify the vehicle.

It can be found on the identification

plate attached to apron panel located

on the driver's side of the engine com-

partment.

SSA8010B

HFC600

Diesel engine

SI010B1-E

Engine Number

Petrol engine (1.6 DOHC)

I010B02B

HFC6001

The engine number is stamped on the

I010B02E

engine block as shown in the drawing.

fcuk-8.p65

2

12/27/2006, 10:17 AM