Hummer H1 (2002+). Manual - part 168

_____________________________________________________________________

Body 10-43

®

05745159

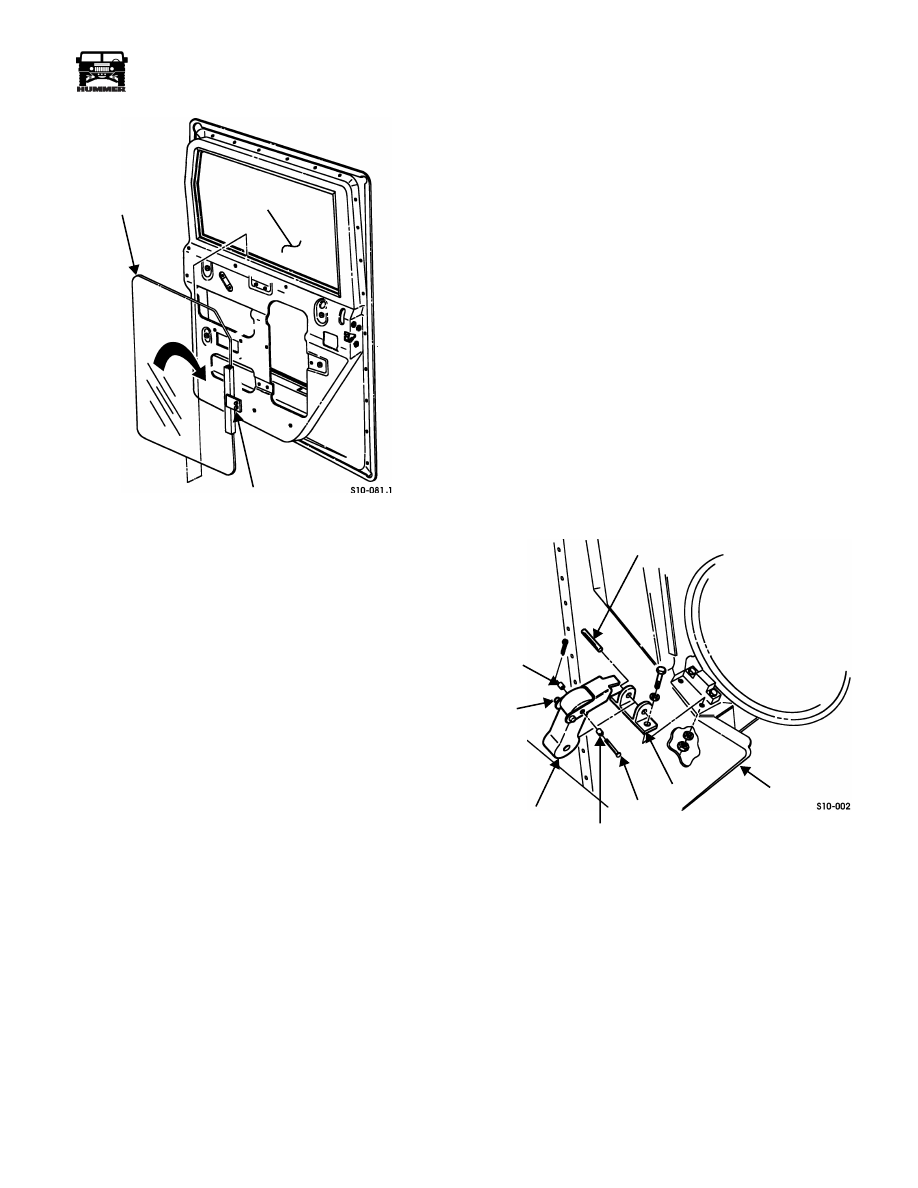

Figure 10-73: Glass/Lift Channel Bracket

Location

Door Glass “Wind Noise” Diagnosis and

Repair/Side Window Alignment

Wind noise or whistle generating from the side windows at

highway speeds is the result of inadequate sealing of the glass

at the upper seal. The glass must be properly aligned in the

window opening, adjust door glass as follows:.

1.

Loosen, but do not remove, lift channel bracket mounting

bolts.

2.

Place block of wood (or equivalent symmetrical object)

across upper seal of window opening.

3.

Roll window up so that glass contacts block of wood and

squares itself on window opening.

4.

Tighten lift channel bracket mounting bolts.

5.

Verify proper window operation.

HOOD, HOOD LATCH, AND PROP ROD

Hood Latch and Bracket Replacement

Removal

NOTE:

If only the rubber latch is to be replaced, the spring pin

does not have to be completely out of base.

1.

Remove spring pin and rubber latch from base (Figure 10-74).

2.

Remove two locknuts, washers, bolts, washers, and base

from body.

3.

Remove five locknuts, washers, bolts, latch bracket, latch

plate, and hood latch stop bracket from hood. Discard

locknuts (Figure 10-74).

Disassembly

Remove cotter pin, spring pin, two rollers, and hood latch from

rubber latch (Figure 10-74).

Assembly

Secure hood latch to rubber latch with two rollers, pin, and cot-

ter pin (Figure 10-74).

Figure 10-74: Hood Latch Replacement

Installation

1.

Secure latch plate and hood latch stop bracket to hood with

three bolts, washers, and locknuts. Tighten locknuts to 10

lb-ft (14 N•m) (Figure 10-74).

2.

Secure latch bracket to latch plate with two bolts, washers,

and locknuts. Tighten locknuts to 10 lb-ft (14 N•m).

3.

Apply sealing compound before securing base to body

with two washers, bolts, washers, and locknuts. Tighten

bolts to 6 lb-ft (8 N•m) (Figure 10-74).

4.

Secure rubber latch to base with spring pin.

GLASS

WINDOW

LIFT CHANNEL BRACKET

SPRING PIN

BODY

BASE

PIN

ROLLER

RUBBER

HOOD

ROLLER

LATCH

LATCH

Section 10 Body