Great Wall Florid. Manual - part 27

GWFLORID Maintenance Manual

106

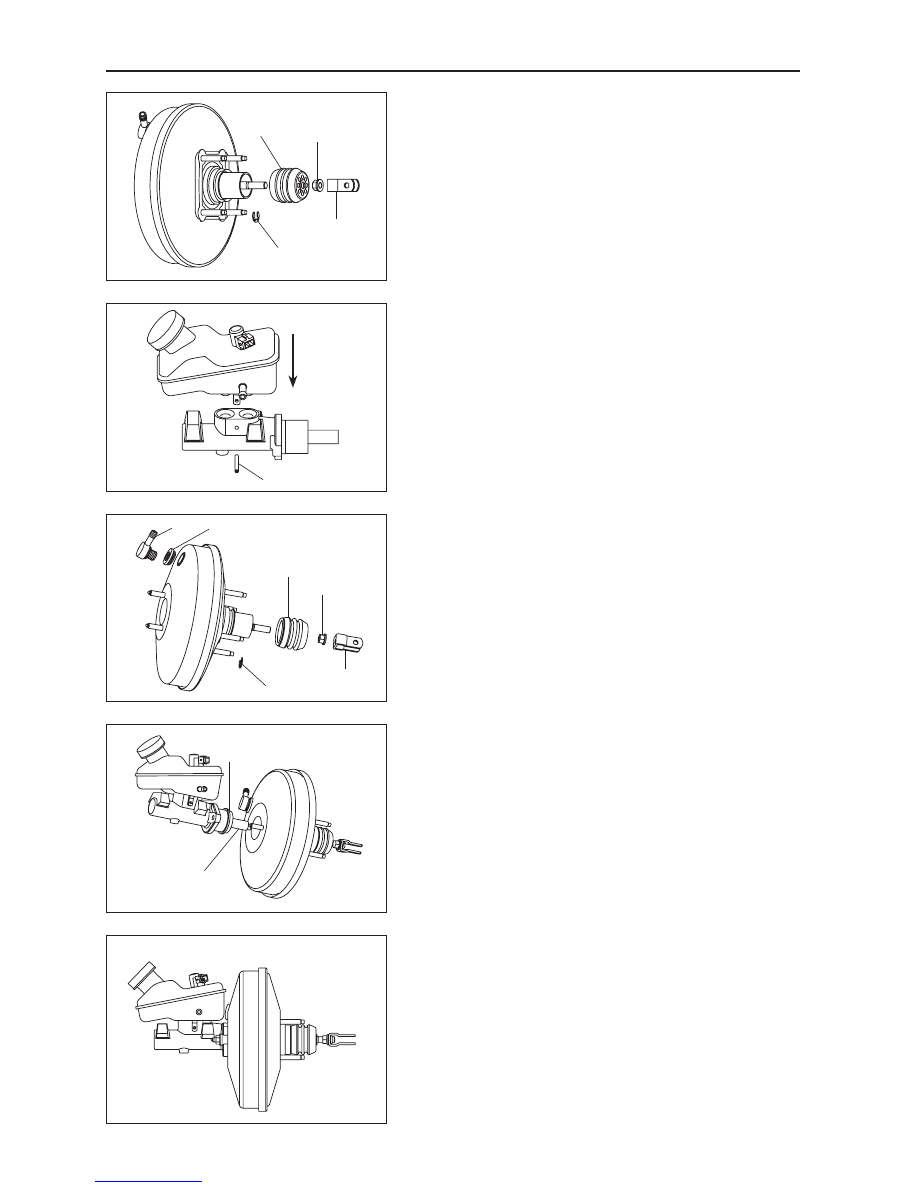

4. Remove the dust cover.

If necessary to replace the dust cover, replace it using the

following steps.

(a) Twist off the rod clevis.

(b) Screw off the nut.

(c) Pull out the split ring.

(d) Pull out the dust cover.

Removal of the vacuum booster with brake cylinder

assembly is now complete.

Vacuum booster with brake cylinder assem-

bly installation

1. Install the brake cylinder assembly.

Tighten the cover of the brake reservoir, place the outlet

port of the brake reservoir against the master cylinder inlet,

push the brake reservoir assembly into the master cylinder

assembly, and then insert the cylindrical pin to complete the

installation.

Caution: Check and ensure the cleanliness of the

reservoir outlet port and master cylinder inlet. Do not

lose the sealing ring inside the master cylinder inlet.

2. Installation of the vacuum booster assembly.

Install each part of booster using the following steps.

(a) Install the check valve seat.

(b) Install the check valve.

(c) Install the dust cover.

(d) Install the split ring.

(e) Install the lock nut.

(f) Install the rod clevis.

3. Installaion of the vacuum booster assembly and brake

cylinder assembly.

(a) Install the rectangular sealing ring, and then place the

brake pump assembly into the front case’s housing. Pay

attention when pushing the booster's push rod head into

the first piston hole.

(b) Put the two holes of the cylinder body’s flange surface

into the front case bolts of the vacuum booster, and

then tighten the nuts with a torque wrench.

Tightening torque: 20-26 N·m

4. The installation of the vacuum booster with brake

cylinder assembly is the reversed procedure of its

removal. Hence no more elaboration will be provided

here.

Tightening torque of the four lock bolts on the brake

pedal: 23±3 N·m

Tightening torque of master cylinder outlet port rigid

pipe: 15 N·m

Rod clevis

Nut

Split ring

Dust cover

Elastic cylindrical pin

Check valve Check valve seat

Lock nut

Rod clevis

Split ring

Dust cover

Rectangular sealing ring

First piston