Ford F150 Pickup. Instruction - part 646

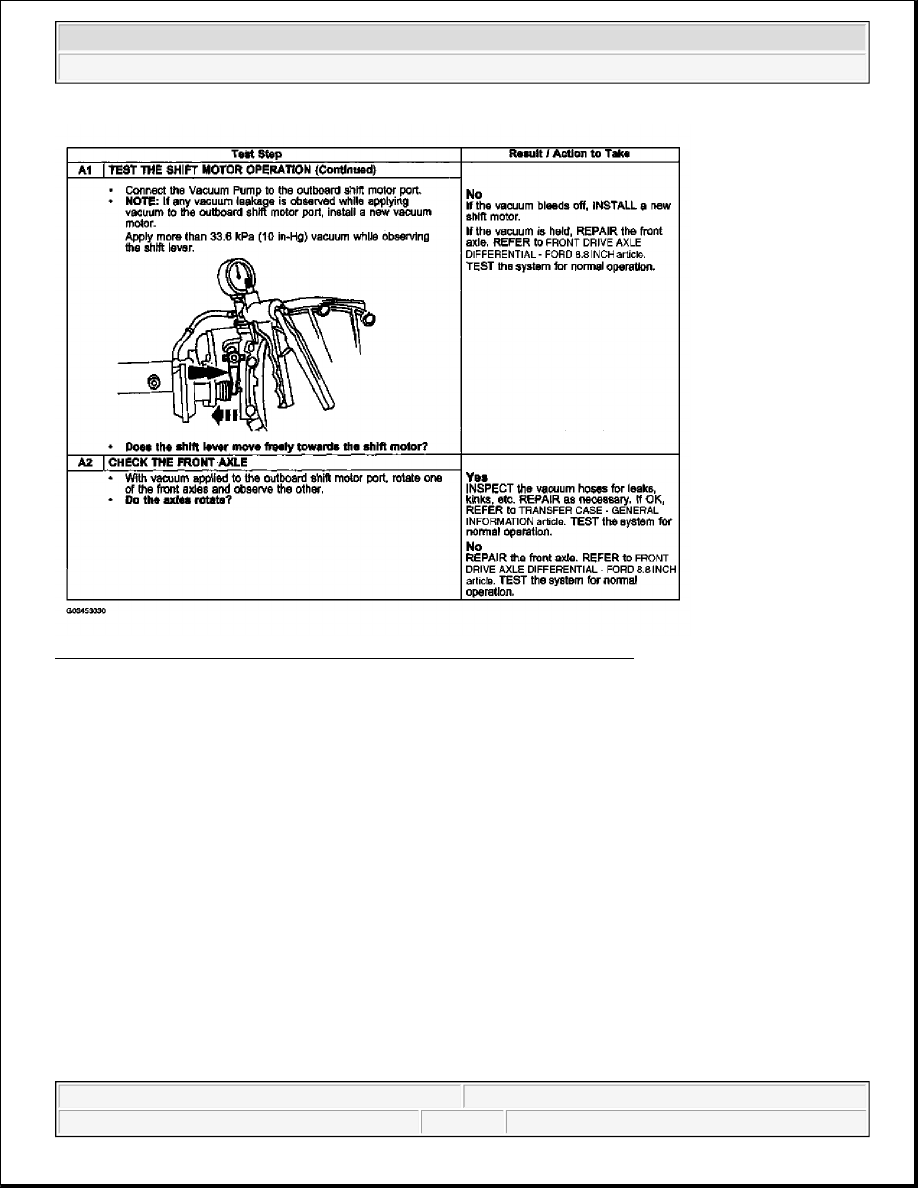

Fig. 23: Pinpoint Test A: Front Axle Will Not Engage Step (A1 Cont. & A2)

Courtesy of FORD MOTOR CO.

PINPOINT TEST B: FRONT AXLE WILL NOT DISENGAGE

2003 Ford Pickup F150

2003 GENERAL INFORMATION Driveline System - General Information - F150 Pickup