Content .. 1631 1632 1633 1634 ..

Ford F150 Pickup. Instruction - part 1633

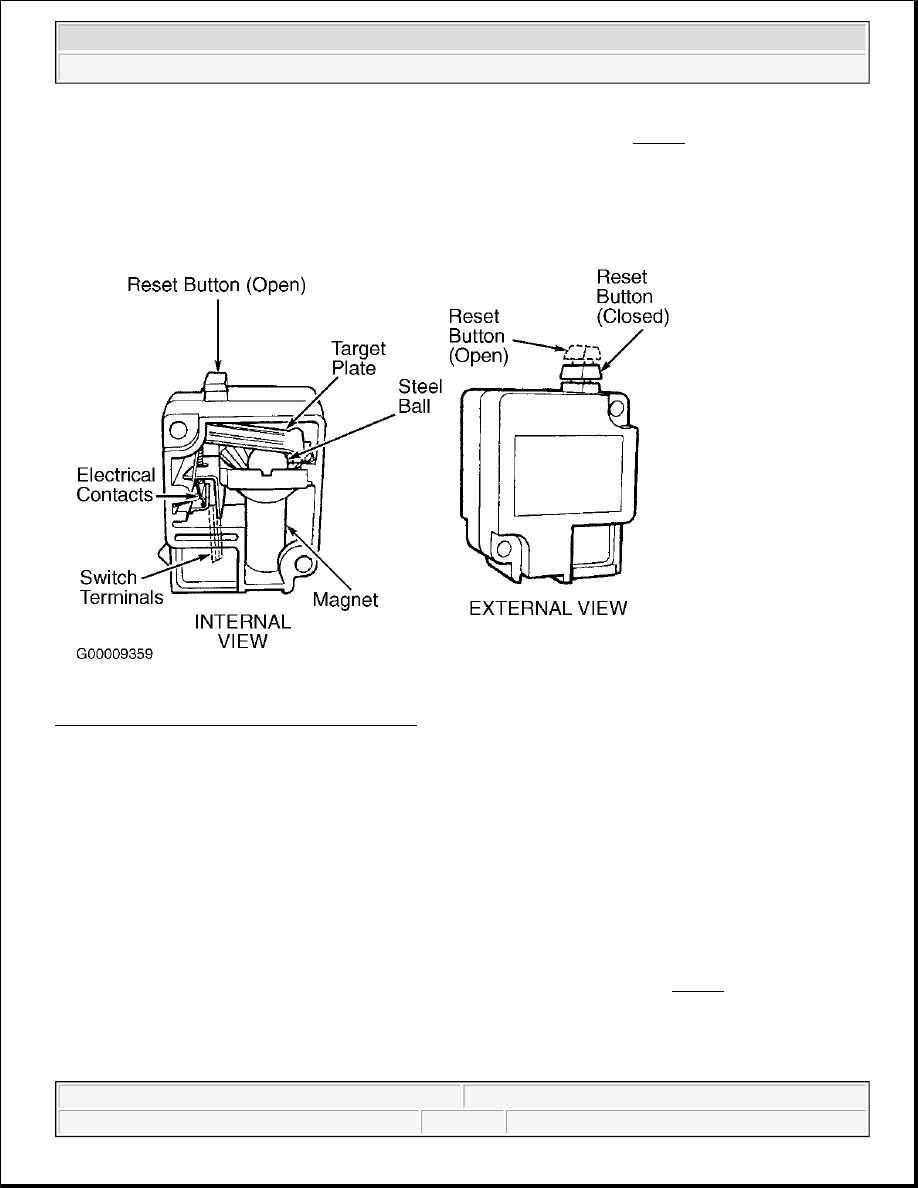

tripped open when the internal steel ball breaks loose of the switch magnet. See Fig. 40 . Once loose, the steel

ball rolls up a conical ramp and makes contact with the target plate which creates an open in the electrical

circuit to electric fuel pump. If the electrical circuit is opened, it is not possible to restart the vehicle until the

switch is reset. A reset button is located on top of IFS switch assembly.

Fig. 40: Identifying Inertia Fuel Shutoff Switch

Courtesy of FORD MOTOR CO.

FUEL CONTROL

Fuel Injectors

The fuel injector is a solenoid-operated valve that meters fuel flow to the engine. See Fig. 41 . The fuel injector

is opened and closed a constant number of times per crankshaft revolution. The amount of fuel is controlled by

the length of time the fuel injector is held open.

The fuel injector is normally closed and is operated by 12 volt VPWR from the electronic engine control power

CAUTION: DO NOT apply battery voltage directly to fuel injector electrical connector

terminals, internal damage to fuel injector may occur.

NOTE:

Fuel injectors are deposit resistant and must not be cleaned.

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Theory & Operation - CNG, Flex-Fuel & Gasoline