Content .. 1468 1469 1470 1471 ..

Ford F150 Pickup. Instruction - part 1470

Fig. 184: Identifying MAF Sensor Wiring Harness Connector & Circuits (All Others)

Courtesy of FORD MOTOR CO.

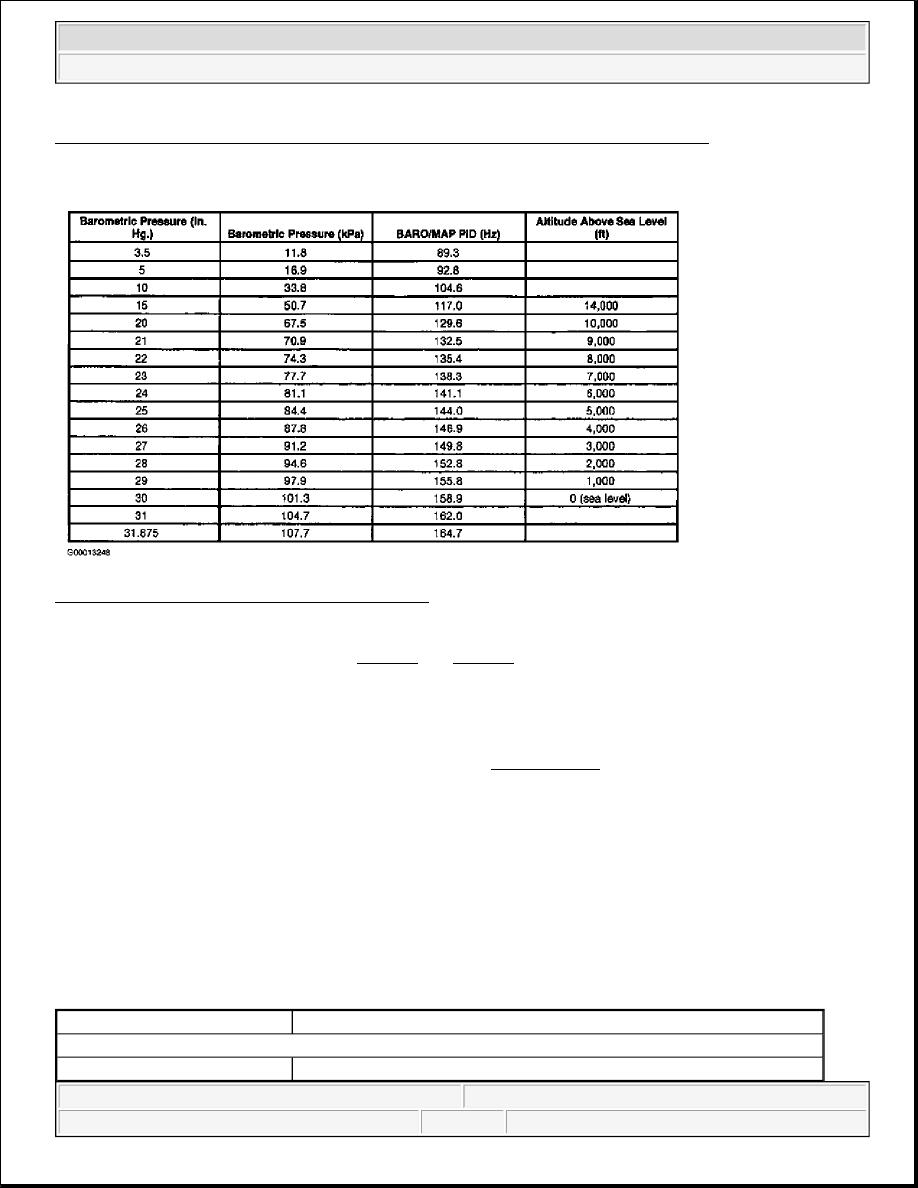

Fig. 185: Barometric Pressure Conversion Chart

Courtesy of FORD MOTOR CO.

For Focus 2.3L, LS and Thunderbird, see Fig. 173 and Fig. 174 .

TEST DD: FUEL RAIL PRESSURE SENSOR

Diagnostic Aids

Perform this test when directed by QUICK TEST. This test is intended to diagnose the following:

z

FRP Sensor

z

Wiring Harness Circuits (FRP & SIG RTN)

z

Powertrain Control Module (PCM)

FRP SENSOR VOLTAGE-TO-FUEL PRESSURE CONVERSION

NOTE:

After each service or repair procedure has been completed, reconnect all

components. Clear DTCs and repeat QUICK TEST procedures to ensure all EEC-

V systems are working properly and DTCs are no longer present.

Volts

psi (kPa)

Natural Gas Vehicles

4.5

150 (1034)

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Self-Diagnostics - CNG, Flex-Fuel & Gasoline