Content .. 1267 1268 1269 1270 ..

Ford F150 Pickup. Instruction - part 1269

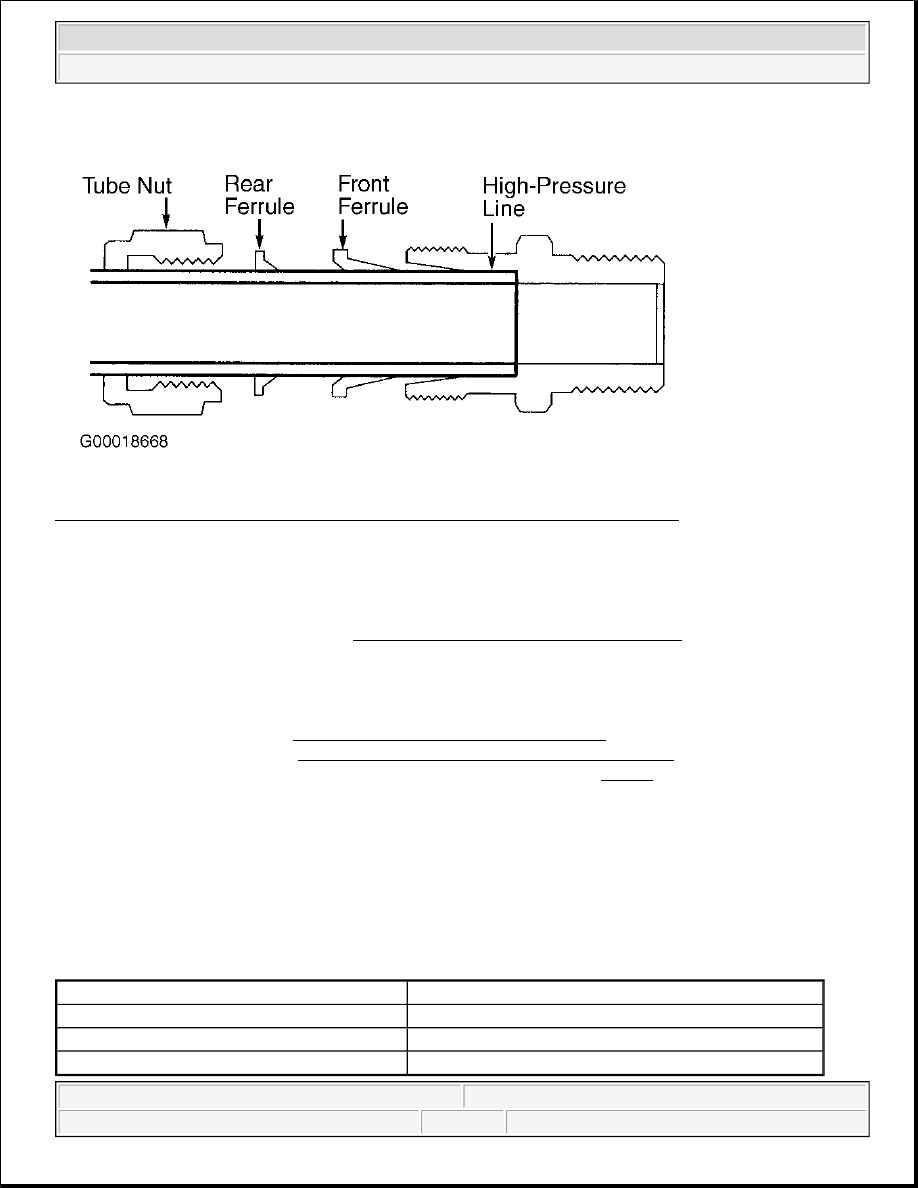

Fig. 24: Removing, Swagging & Installing High Pressure (Gyrolok-Type) Fittings

Courtesy of FORD MOTOR CO.

Connecting (Gyrolok-Type) Fitting

Tighten the fitting in 2 stages. Tighten the tube nut until snug. Tighten an additional 1/2 turn. Pressurize fuel

system and inspect fittings for leaks. See LEAK TEST - ALL BI-FUEL VEHICLES under FUEL SYSTEMS

in SYSTEM & COMPONENT TESTING - BI-FUEL - GASOLINE/CNG article.

Spring Lock Coupling

1. Release fuel pressure. See FUEL SYSTEM PRESSURE RELEASE . Place indicated spring lock

coupler over coupling. See SPRING LOCK COUPLER IDENTIFICATION table. To release female

fitting from garter spring, push coupler along tube into coupling. See Fig. 25 .

2. Pull spring lock coupling apart. Remove coupler from disconnected spring lock coupling. Check for

damaged garter spring and "O" rings. Wipe end of lines with clean cloth.

3. To install, place NEW "O" rings onto tube. Lubricate ends of lines with clean engine oil. Locate White

indicator ring (if equipped), which may have slipped down length of tube. Insert White indicator ring into

cage of male fitting.

4. Push fitting together with a slight twisting motion. White indicator ring will pop free of cage to indicate

that male fitting is properly seated over flared end of female fitting.

SPRING LOCK COUPLER IDENTIFICATION

Application

Tool Number

3/8" Line

D87L-9280-A

1/2" Line

D87L-9280-B

5/8" Line

T83P-19623-C

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Removal & Installation - F150 Pickup - Bi-Fuel - Gasoline/CNG