Content .. 1262 1263 1264 1265 ..

Ford F150 Pickup. Instruction - part 1264

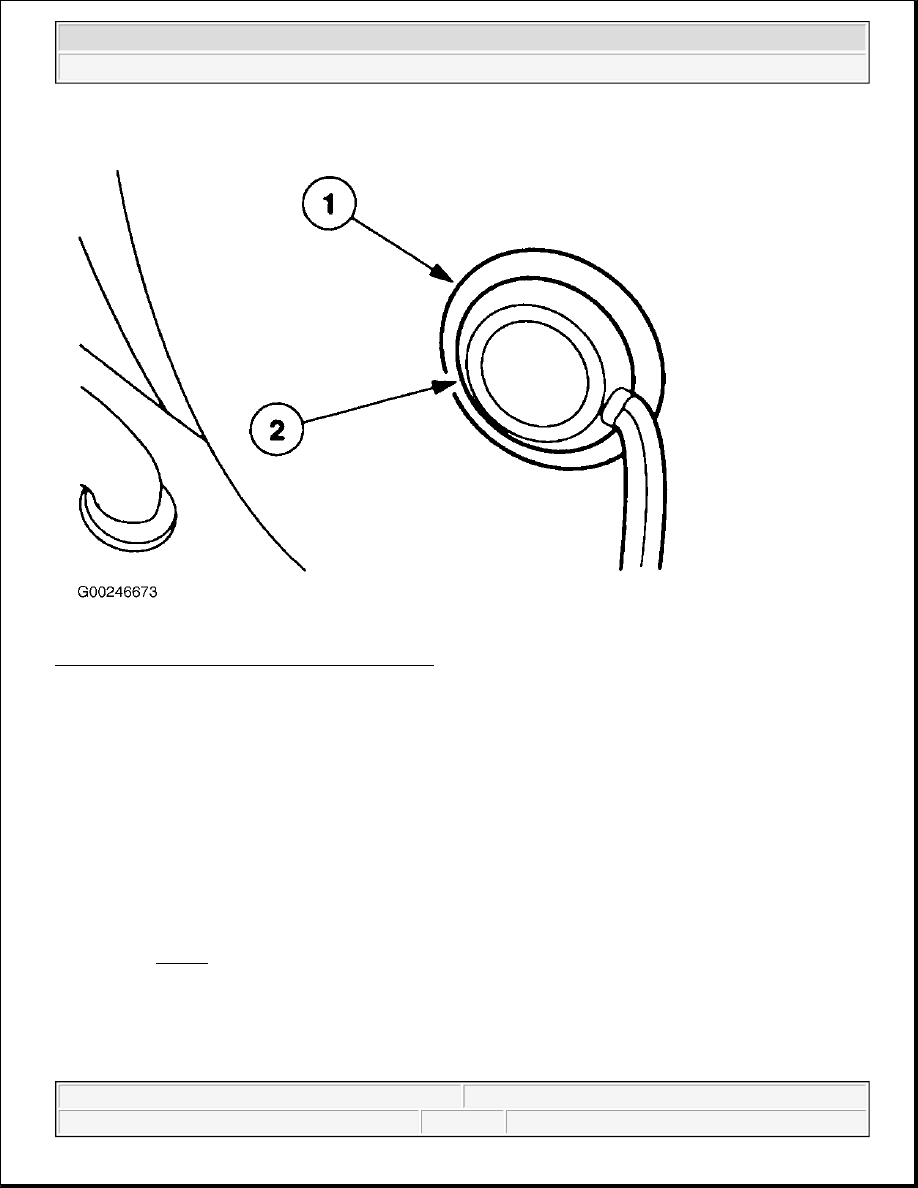

Fig. 9: Removing Fuel Tank Temperature Sensor

Courtesy of FORD MOTOR CO.

RELAYS & SOLENOIDS

BI-FUEL RELAY MODULE

FUEL RAIL SOLENOID

Removal & Installation

The fuel rail solenoid is mounted in fuel rail. The manufacturer does not provide a procedure to replace the

solenoid. See Fig. 10 .

NOTE:

Removal and installation information is not available from manufacturer.

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Removal & Installation - F150 Pickup - Bi-Fuel - Gasoline/CNG