Content .. 1135 1136 1137 1138 ..

Ford F150 Pickup. Instruction - part 1137

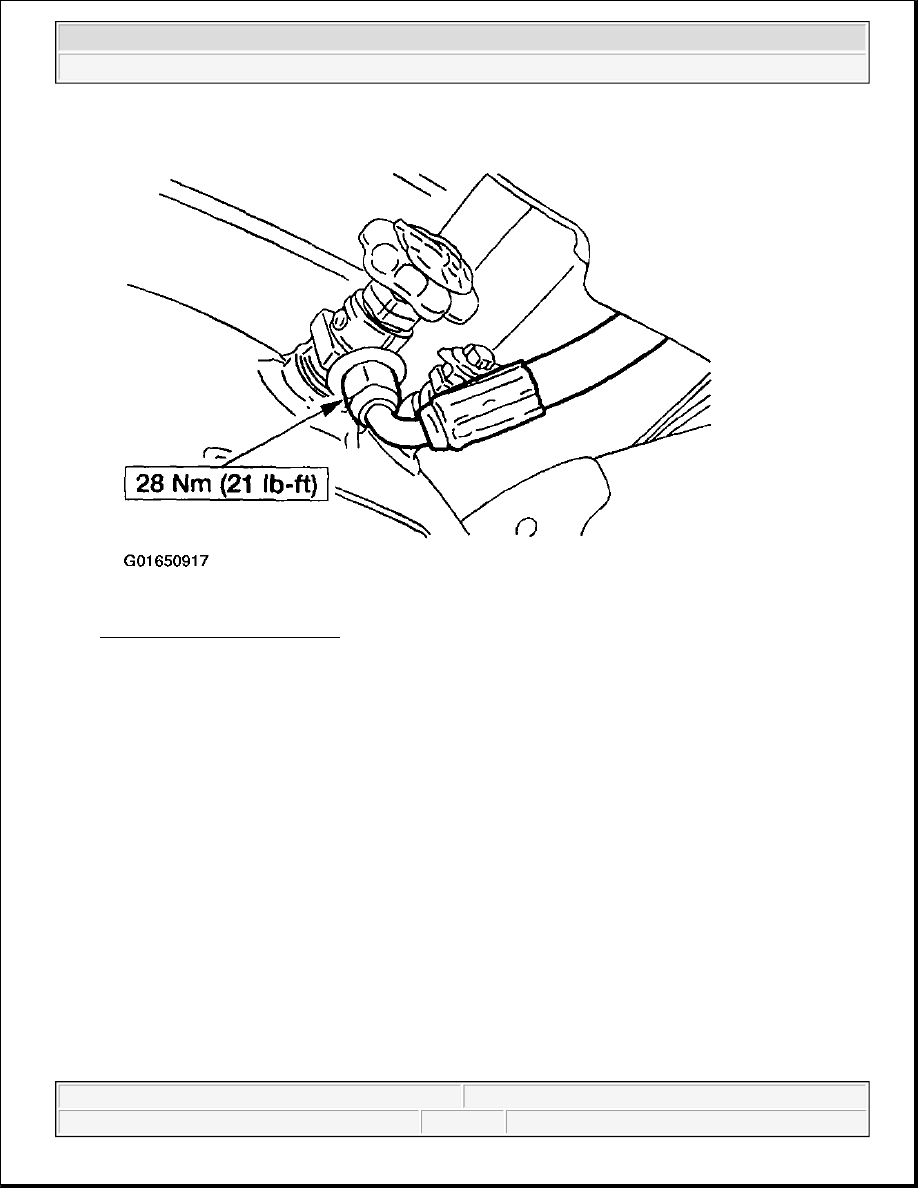

Fig. 9: Disconnecting Fuel Line

Courtesy of FORD MOTOR CO.

2. Slowly disconnect the fuel line.

3. Connect a propane hose to the fuel tank valve and to an approved holding tank supply valve.

4. Slowly open the valve on the fuel tank and the holding tank.

5. Open the fixed liquid level valve on the holding tank.

6. Fully close the supply valves on the fuel and the holding tank if no liquid appears. If liquid is present

continue to evacuate the fuel tank.

7. Disconnect the propane hose from both tanks.

FUEL TANK EVACUATION - NATURAL GAS

Special Tool(s)

NOTE:

If the supply valve is opened too fast, the excess flow valve will close.

2003 Ford Pickup F150

2003 GENERAL INFORMATION Fuel System-General Information-Bi-Fuel - F150 Pickup