Dodge Nitro. Manual - part 121

threads do not contact the scale, the bolt must be replaced. See Fig. 211.

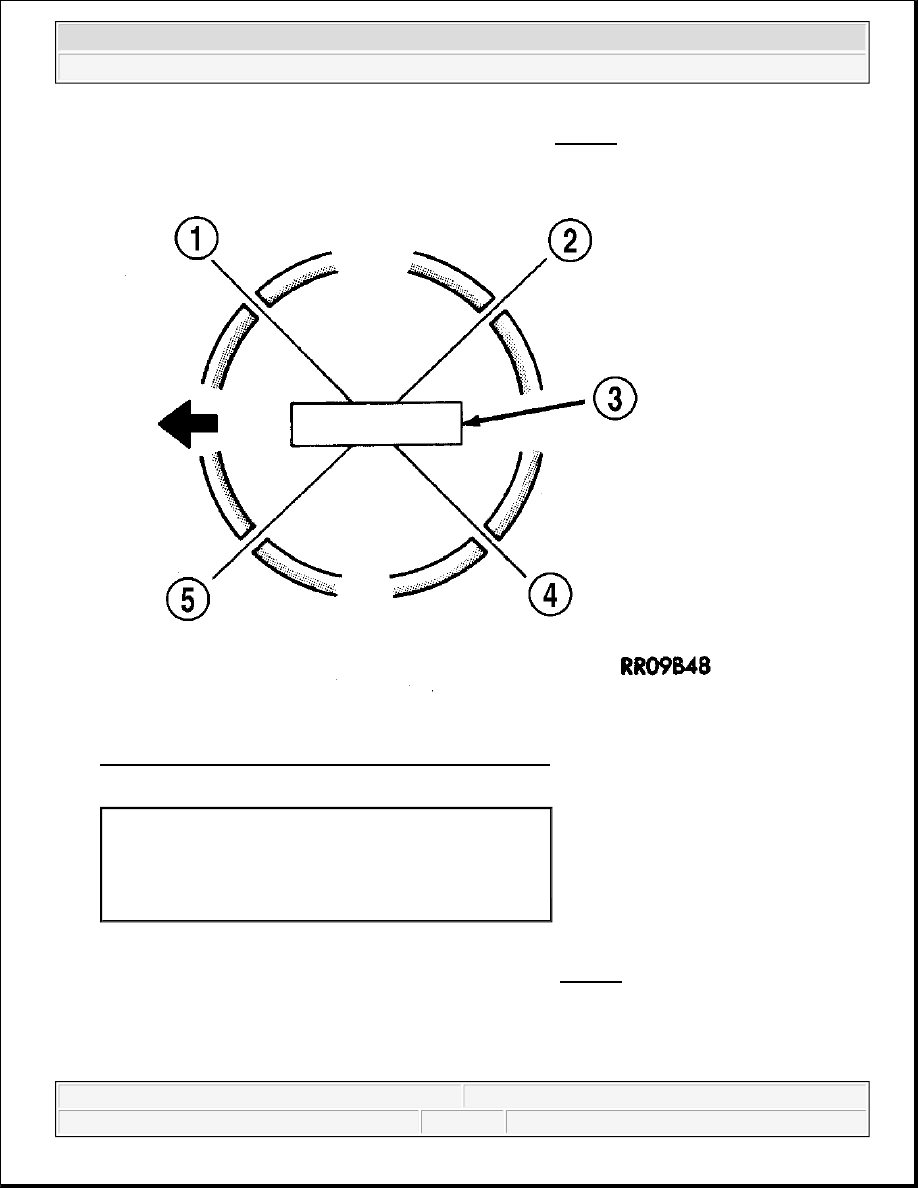

Fig. 212: Ensuring Compression Ring Gaps Are Staggered

Courtesy of CHRYSLER LLC

3. Before installing pistons and connecting rod assemblies into the bore, ensure that compression ring gaps

are staggered so that neither is in line with oil ring rail gap. See Fig. 212.

1 - SIDE RAIL UPPER

2 - NO. 1 RING GAP

3 - PISTON PIN

4 - SIDE RAIL LOWER

5 - NO. 2 RING GAP AND SPACER EXPANDER GAP

2007 Dodge Nitro R/T

2007 ENGINE 4.0L - Service Information - Nitro