Daewoo Musso. Manual - part 95

OM600 ENGINE MECHANICAL 1B3-87

bearing shell

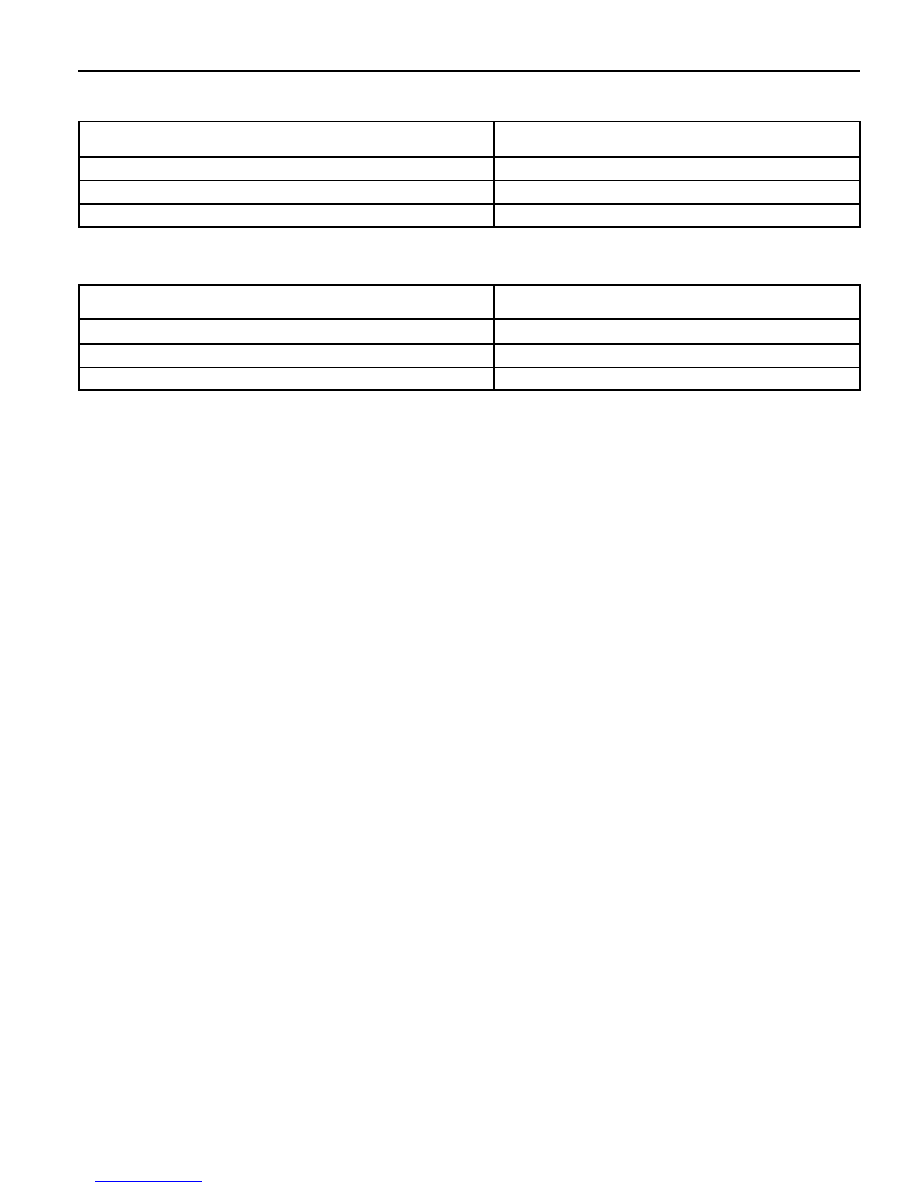

Matching Crankshaft Bearing Shells to Basic Bearing Bore in Crankshaft

Matching Crankshaft Bearing Shells to Basic Bearing Journal of Crankshaft

Marking of basic bearing bore in lower

Color code of relevant crankshaft

parting surface

1 punch mark or blue

2 punch marks or yellow

3 punch marks or red

bearing shell

Blue or white-blue

Yellow or white-yellow

Red or white-red

Marking of bearing journals on crank webs

Color code of relevant crankshaft

Blue or white-blue

Yellow or white-blue

Red or white-blue

Blue or white-blue

Yellow or white-yellow

Red or white-red