Daewoo Tacuma: Body Repair Manual - part 7

3–4 WELDING AND TOOLS

NOTE:

It is difficult to perform spot welding in the following cir-

cumstances.

•

When it is not possible to remove any rust or paint

attached to the welding surfaces.

•

When the tip of the spot welder cannot be inserted

into the welding section.

•

When the welding surfaces can be seen from the

outside and welding will impair the exterior appear-

ance.

In all these cases, it is recommended that the gas weld-

ing method be employed. However, if it is not possible

to perform spot welding because of space restrictions,

plug welding based on the arc welding method may be

performed instead. Here the welding sections must be

close together.

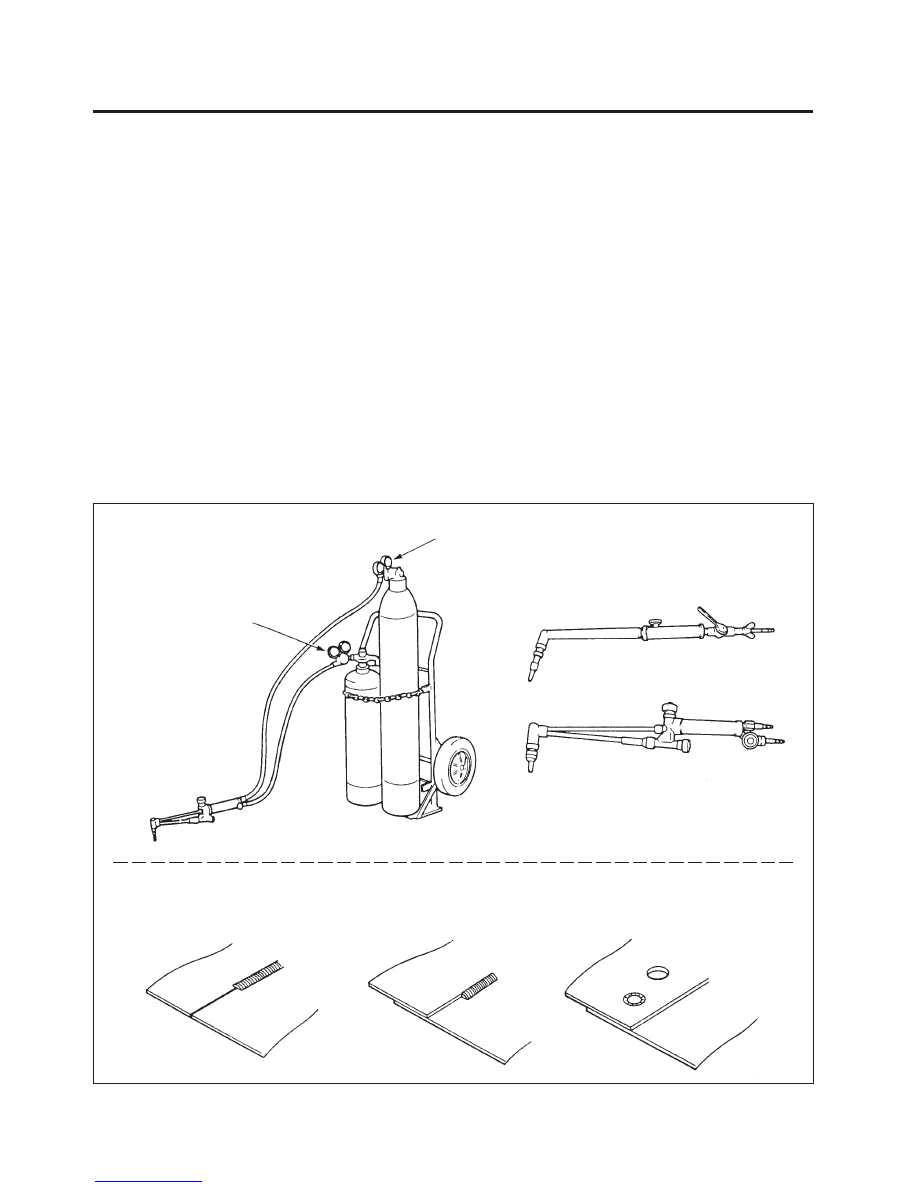

2. GAS WELDING

Gas welding is indispensable for body repair because

of the broad range of its applications from joining the

body panels, cutting the materials that construct the

body and applying heat to reform panels, and also be-

cause it is easy to get hold of the tools.

However, this method requires experience.

Fig. 5

WELDERS:

WELDING METHODS:

BUTT WELDING

WELDER

CUTTER

OXYGEN/ACETYLENE TANKS

GAS ADJUSTER

GAS ADJUSTER

DRILLING AND PLUG WELDING

FILLET WELDING OR SOLDERING