Daewoo Korando. Manual - part 34

1B1-72 M162 ENGINE MECHANICAL

Installation Procedure

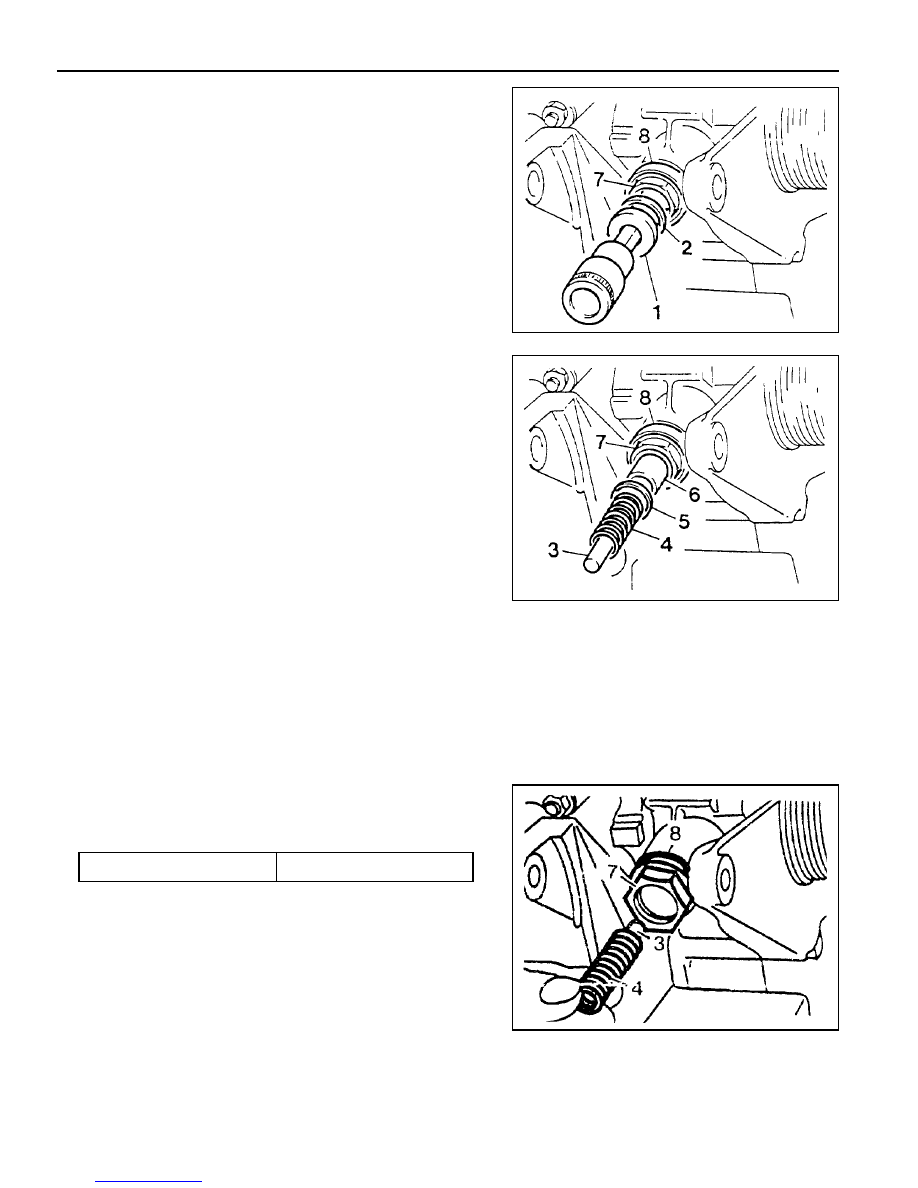

1. Connect the thrust pin (6) and the snap ring (5) to the chain

tensioner housing (7).

Notice

When connecting the thrust pin, push in the thrust pin far

enough so that it doesn’t protrude at the chain tensioner

housing.

4. Carefully unscrew the screw plug (1), and remove the seal

(2).

Notice

l

For the removal of screw plug, be careful that it can be

jumped out due to the force of compression spring.

l

Remove the screw plug only when the seal and

compression spring are damaged.

5. Carefully remove the filler pin (3), compression spring (4),

snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal (8).

3. Insert the compression spring (4) with the filler pin (3) into

chain tensioner housing.

2. Install the chain tensioner housing (7), thrust pin (6), snap

ring (5), and the seal (8).

Installation Notice

Tightening Torque

35 - 40 Nm