DAF CF65, CF75, CF85 Series . Manual - part 964

©

200423

4-1

Removal and installation

STEERING BOX

ΧΦ65/75/85 series

7

3

4. REMOVAL AND INSTALLATION

4.1 REMOVAL AND INSTALLATION, ENTIRE STEERING BOX

If the vehicle has been involved in a

collision in which the steering box or

other components of the steering

gear have (possibly) been damaged,

the steering box should always be

sent to DAF for inspection or be

replaced. This instruction even

applies if no external damage is

visible. In the collision, the steering

box may have sustained internal

damage, causing it to be unreliable.

Removing the entire steering box

1.

Clean the steering box and the surrounding

area.

2.

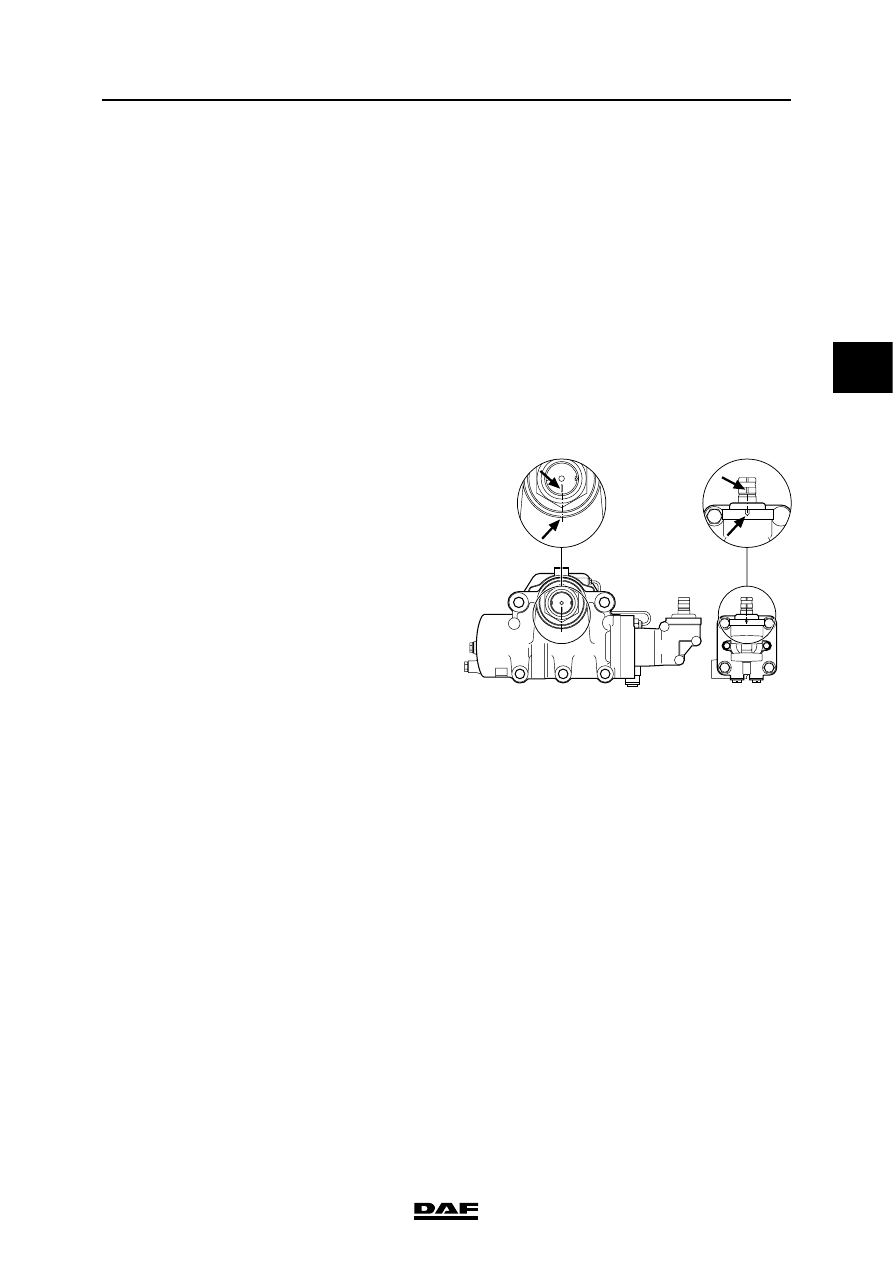

Place the steering gear in the central

position. This can be checked using the

markings on the steering box.

3.

With an EMAS-controlled trailing axle,

remove the connector from the angle sensor.

4.

Remove the steering oil pipes from the

steering box. Collect the steering oil flowing

out and plug the openings of the pipes and at

the steering box, to prevent dirt entering.

Note:

If the pipe connections might accidentally be

switched, they should be marked.

5.

Remove the steering rod from the pitman

arm.

Note:

When a steering rod has been removed, the

input shaft must not be rotated more than

1.5 turns (counting from the central position)

because otherwise the setting of the wheel

deflection limiting valves will be changed.

6.

If present, detach the wiring harness and/or

other pipes from the steering bracket.

7.

Remove the steering shaft from the steering

box input shaft.

Note: The steering box weighs

approx. 35 kg. The steering box

should be supported securely and

responsibly, or safely suspended in

a hoist.

}

S7 00 024

}