DAF CF65, CF75, CF85 Series . Manual - part 957

©

200423

4-7

Draining and filling

STEERING GEAR, GENERAL

ΧΦ65/75/85 series

7

2

15. Run the engine at idling speed for another

2 minutes. Do not touch the steering wheel

during these 2 minutes.

16. Check the steering oil level when the engine

is not running.

17. Clean the dipstick and its immediate

surroundings so that no dirt can get into the

reservoir.

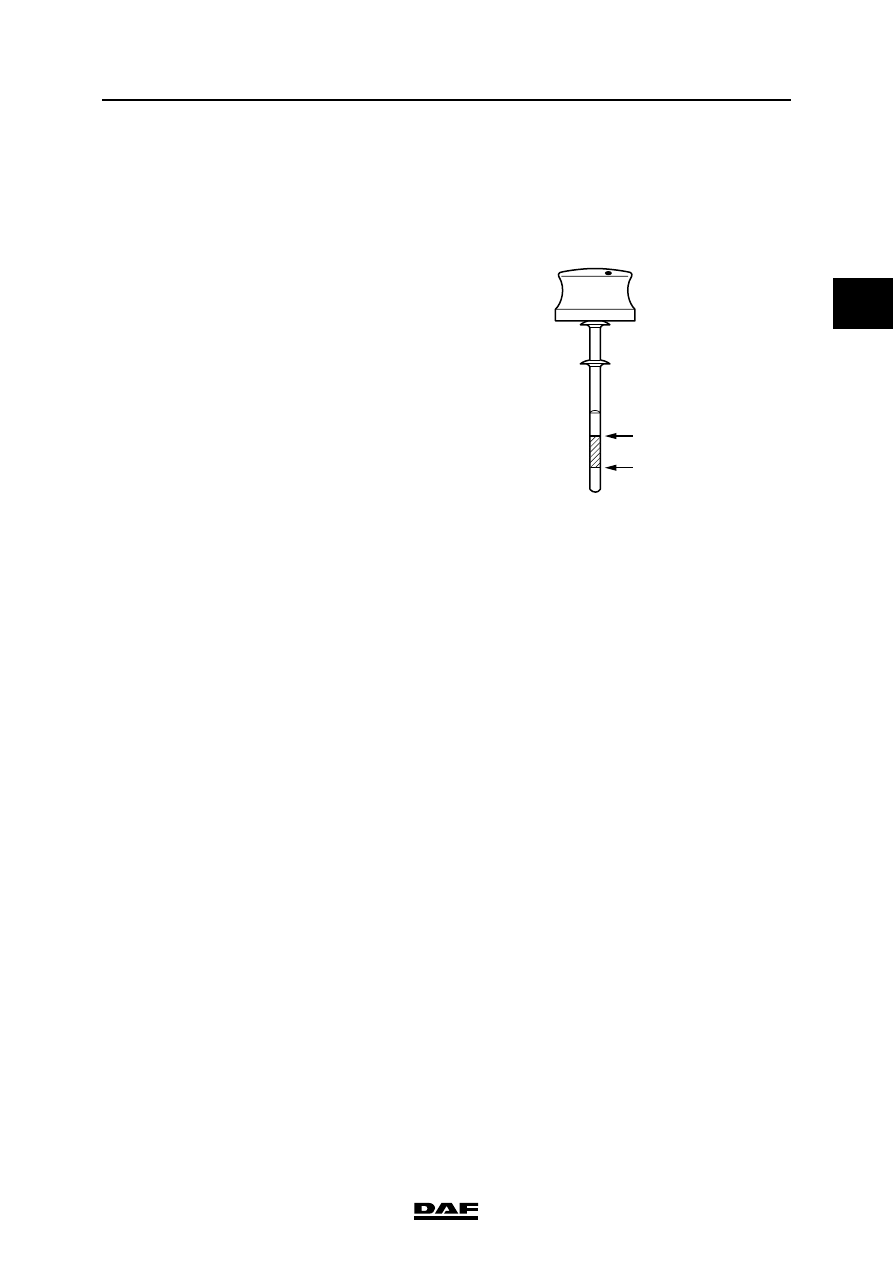

18. Check the fluid level in the reservoir using

the dipstick.

19. The fluid level should be between the marks

when the steering oil is "cold".

Note:

When the steering oil is at operating temperature,

the level may be above the top mark on the

dipstick.

20. Put the filler cap on the reservoir again and

lower the axle(s).

21. Inspect the line connections for leaks.

22. Attach the propeller shaft.

23. Make a test drive. Now check the steering oil

level and check the line connections for

leaks.

S7 00 676