DAF CF65, CF75, CF85 Series . Manual - part 956

©

200423

4-3

Draining and filling

STEERING GEAR, GENERAL

ΧΦ65/75/85 series

7

2

7.

Jack up the steerable axle(s) until the wheels

are clear of the floor.

Note:

If the wheel deflection limiting valves are

incorrectly set, e.g. because the maximum

wheel deflection is increased, these valves

should be set correct first.

8.

Start the engine and, with the engine

running, slowly turn the steering wheel

(approx. a

∂ turn of the steering wheel per

second) to the left and to the right, until the

maximum wheel deflection is reached.

Continue this until the oil level no longer

decreases.

Watch the steering oil level, especially if the

vehicle is equipped with a slave cylinder.

9.

Run the engine at idling speed for another 2

minutes. Do not touch the steering wheel

during these 2 minutes.

10. Check the steering oil level when the engine

is not running.

11. Clean the dipstick and its immediate

surroundings so that no dirt can get into the

reservoir.

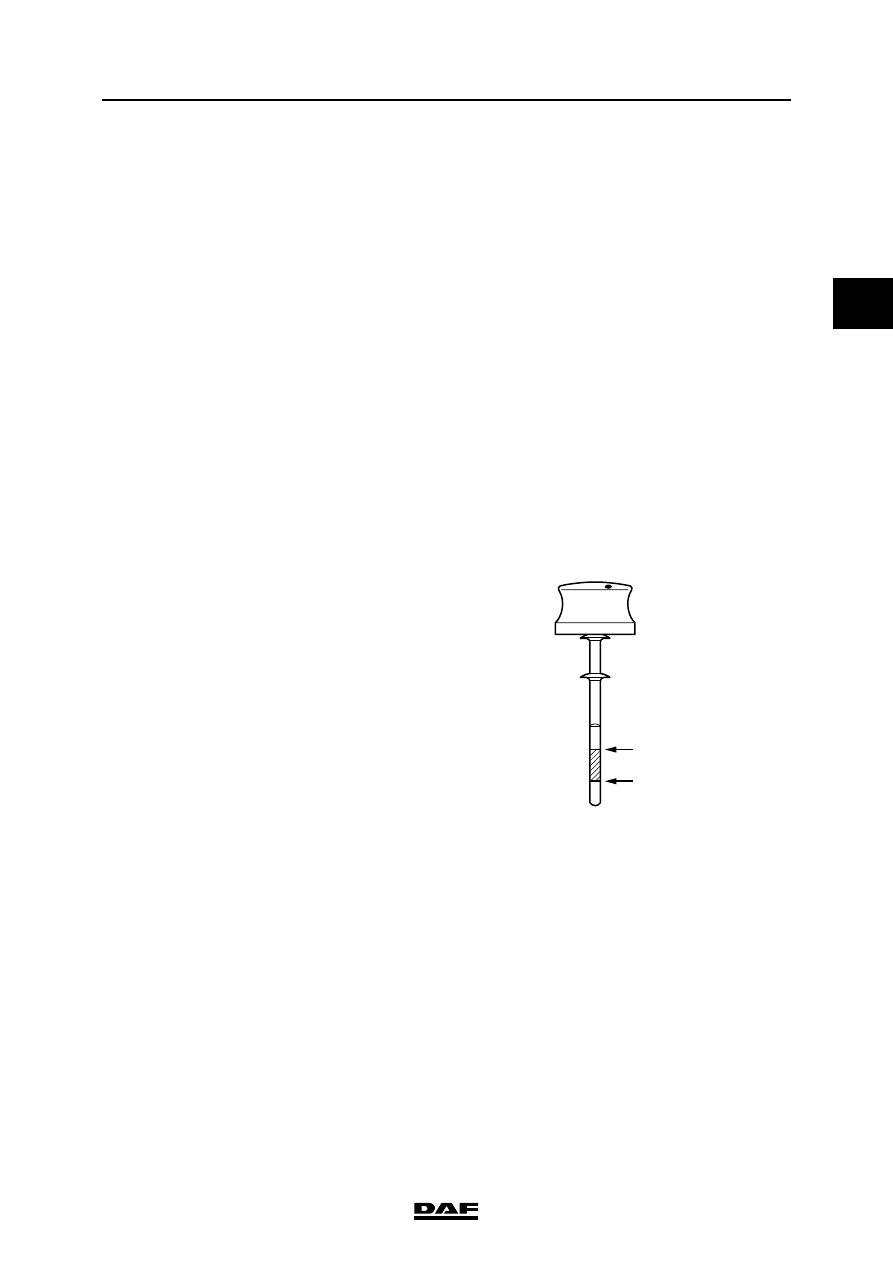

12. Check the fluid level in the reservoir using

the dipstick.

13. The fluid level should be between the marks

when the steering oil is "cold".

Note:

When the steering oil is at operating temperature,

the level may be above the top mark on the

dipstick.

Note:

If the vehicle is equipped with a slave cylinder, it

may be necessary in some cases to bleed the

slave cylinder separately.

To do so, slightly loosen the union nuts of both

connections while the engine is running, and no

steering action is taking place. Any air can now

escape.

14. Put the filler cap on the reservoir again and

lower the axle(s).

15. Inspect the line connections for leaks.

16. Make a test drive. Now check the steering oil

level and check the line connections for

leaks.

S7 00 676