DAF CF65, CF75, CF85 Series . Manual - part 477

©

200324

3-1

Inspection and adjustment

XE ENGINE INLET/EXHAUST SYSTEM

CF65/75/85 series

4

9

3. INSPECTION AND ADJUSTMENT

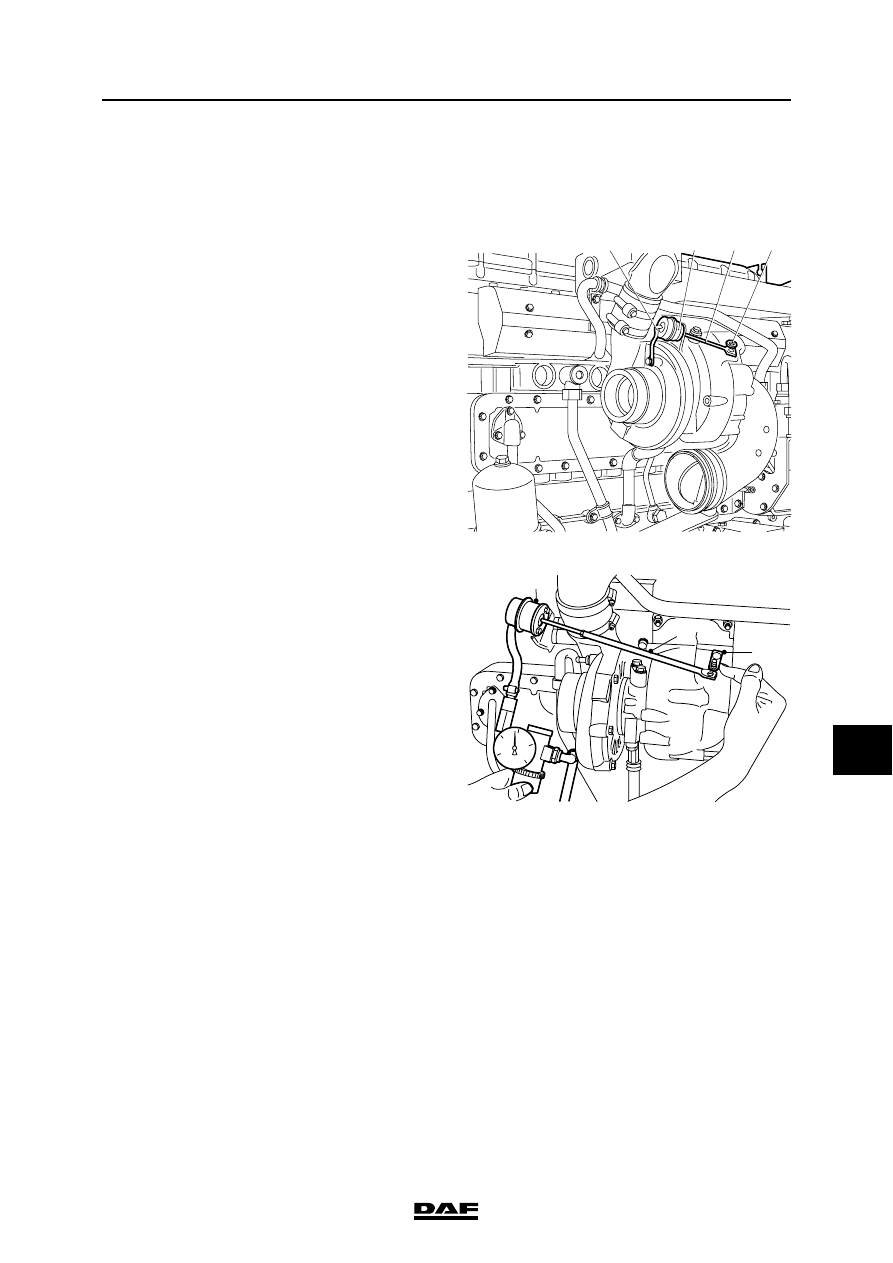

3.1 INSPECTING AND ADJUSTING TURBOCHARGER WASTEGATE

1.

Remove the heat shield from the

turbocharger.

2.

Remove the air supply connector (1) from

the diaphragm housing (2).

3.

Remove the retaining clip (3) and remove the

control rod (4) from the wastegate lever.

4.

Using a reducer valve, apply the specified

adjusting pressure to the connection with the

diaphragm housing (see "Technical data").

5.

Push the wastegate lever (5) fully to the left

to close the wastegate valve.

6.

Adjust the length of the control rod (4),

making sure it fits exactly onto the lever at

the set pressure.

7.

Inspect the adjustment of the wastegate

using the specified pressure. See "Technical

data".

8.

Fit the retaining clip (3).

I400532

3

1

4

2

i 400214

4

3

2

1

0

5

4

2