DAF CF65, CF75, CF85 Series . Manual - part 455

©

200324

2-3

General

PE ENGINE INLET/EXHAUST SYSTEM

CF65/75/85 series

4

6

2.2 SYSTEM DESCRIPTION, TURBOCHARGER

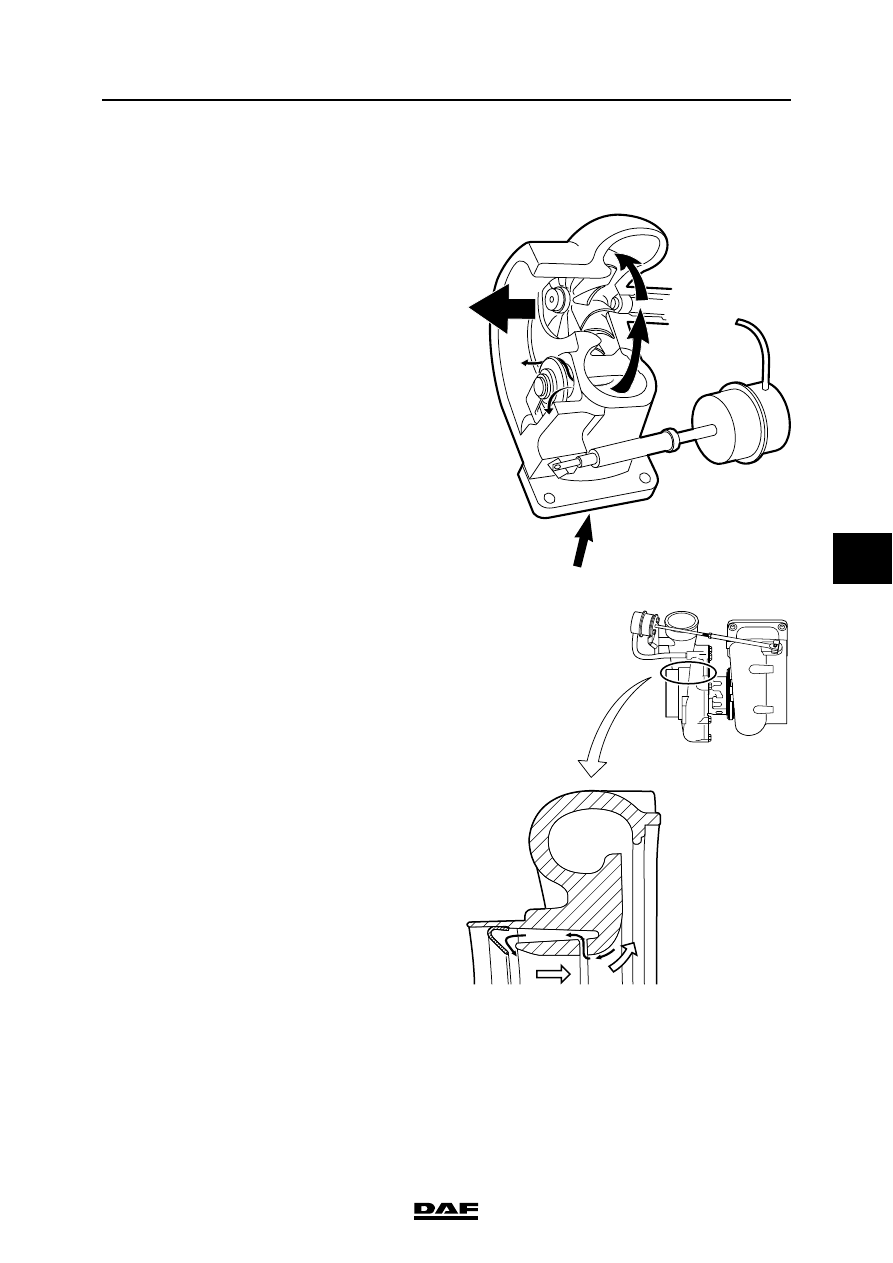

Wastegate

To make the engine more responsive at lower

engine speeds, a turbocharger is used that

produces a better charge ratio at these speeds.

Without provision having been made for this, the

boost pressure yielded by this turbocharger

would be too high at maximum engine speeds.

Use of a wastegate prevents this.

The turbocharger's compressor housing has an

air coupling connected to a diaphragm. The boost

pressure yielded by the turbocharger operates

the diaphragm and the control rod connected to it.

The control rod operates a valve in the turbine

housing.

The valve in the turbine housing is opened when

the maximum pre-set pressure has been

reached.

When the valve is opened, some of the exhaust

gases will be discharged directly to the exhaust

pipe rather than being used to propel the

turbocharger's turbine wheel.

Compression housing by-pass

At higher boost pressures, the turbocharger

compressor tends to allow this pressure to return

to the intake underpressure area. To prevent this,

the turbocharger's compression housing has

been adapted.

This adaptation consists of bypass ducts and a

stop plate.

Boost pressure attempting to return to the intake

area will do so at the outer circumference of the

compression housing.

The compression housing has been fitted with an

air slot to force this pressure to flow back through

special air ducts on the outside until it is arrested

by the stop plate.

i400309

i 400212