DAF CF65, CF75, CF85 Series . Manual - part 434

©

200416

3-5

Inspection and adjustment

CE ENGINE INLET/EXHAUST SYSTEM

ΧΦ65/75/85 series

4

3

3.5 INSPECTION AND PRESSURE-TESTING, AIR INLET SYSTEM

When pressure-testing the air inlet

system, the plugs may spring off if

they are not properly secured. It is

therefore important to check the

attachment of the plugs before

pressure-testing and keep people

away from the area.

1.

Check the condition and mounting of the air

inlet channels/pipes of the air inlet system.

Note:

In case of doubt as to the proper sealing of

the air inlet system, which is indicated by the

following:

- loss of power

- high fuel consumption

- unusual noises

- lit engine fault symbol on the instrument

panel, ???carry out a pressure test to check

the air inlet system for leakage.

2.

Remove the right-hand and rear engine

encapsulations.

3.

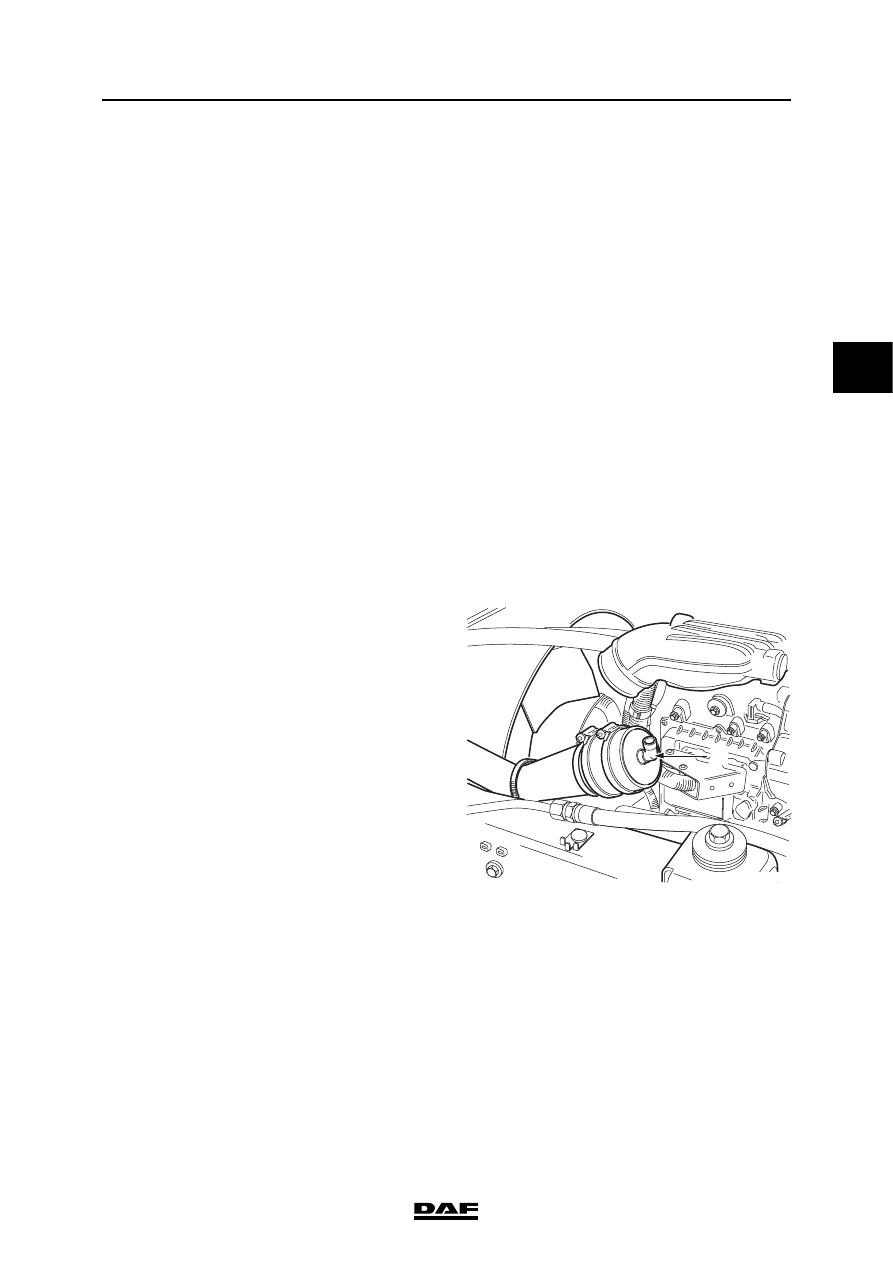

Loosen the inlet hose between the air cooler

and the inlet manifold at the inlet manifold

side.

4.

Fit the special tool (DAF no. 1453171) in the

hose.

}

A

i400856