DAF CF65, CF75, CF85 Series . Manual - part 426

©

200416

5-13

Removal and installation

CE ENGINE FUEL SYSTEM

ΧΦ65/75/85 series

4

2

9.

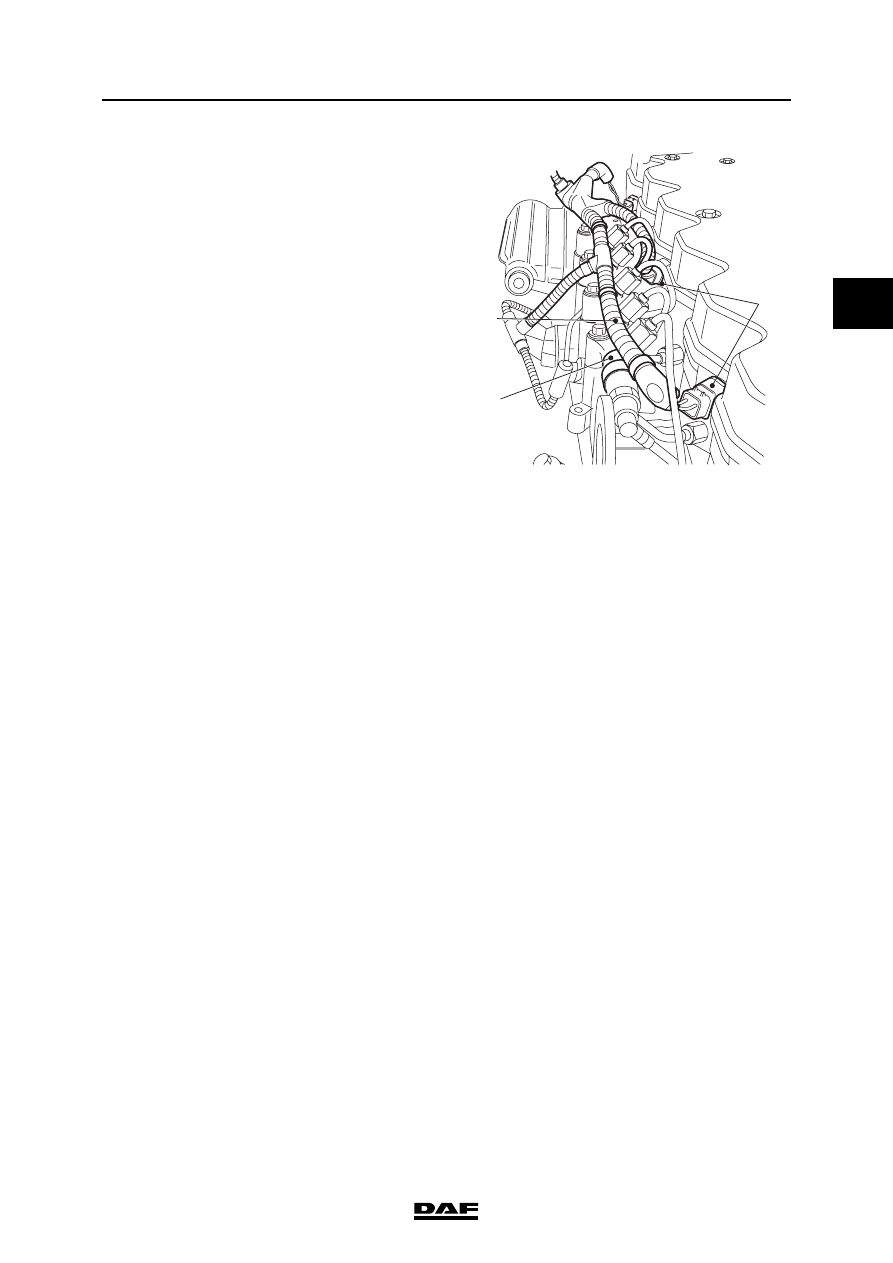

Install the cable harness (3) to the fuel rail (2)

and secure it using cable ties.

10. Fit the connectors of the injectors (1) in the

valve sleeve.

11. If it has been removed, fit the plug of the inlet

air temperature/boost pressure sensor to the

sensor.

12. Fit the connector of the fuel rail pressure

sensor.

13. Start the engine and check the fuel system

for leaks.

i400809

3

1

2