DAF CF65, CF75, CF85 Series . Manual - part 416

©

200416

2-5

General

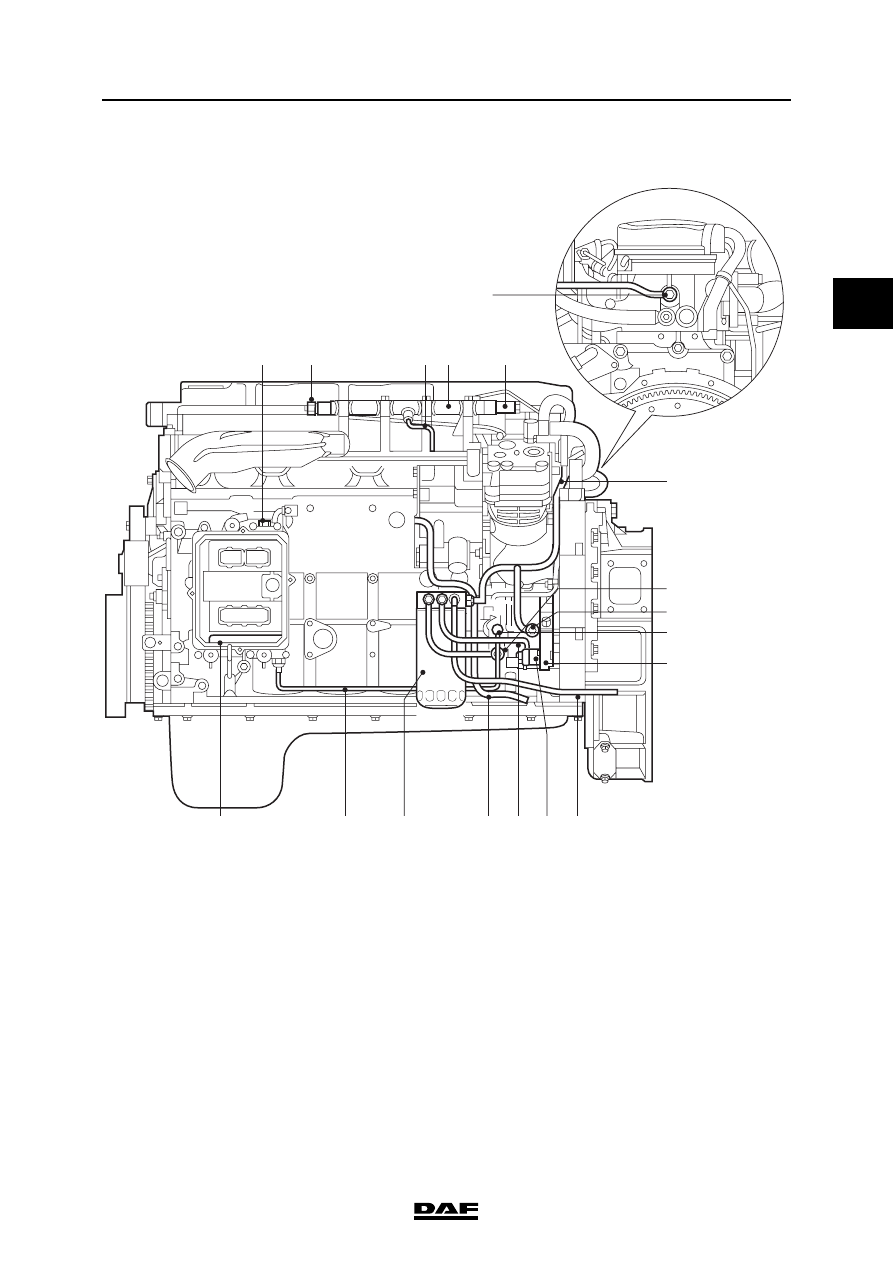

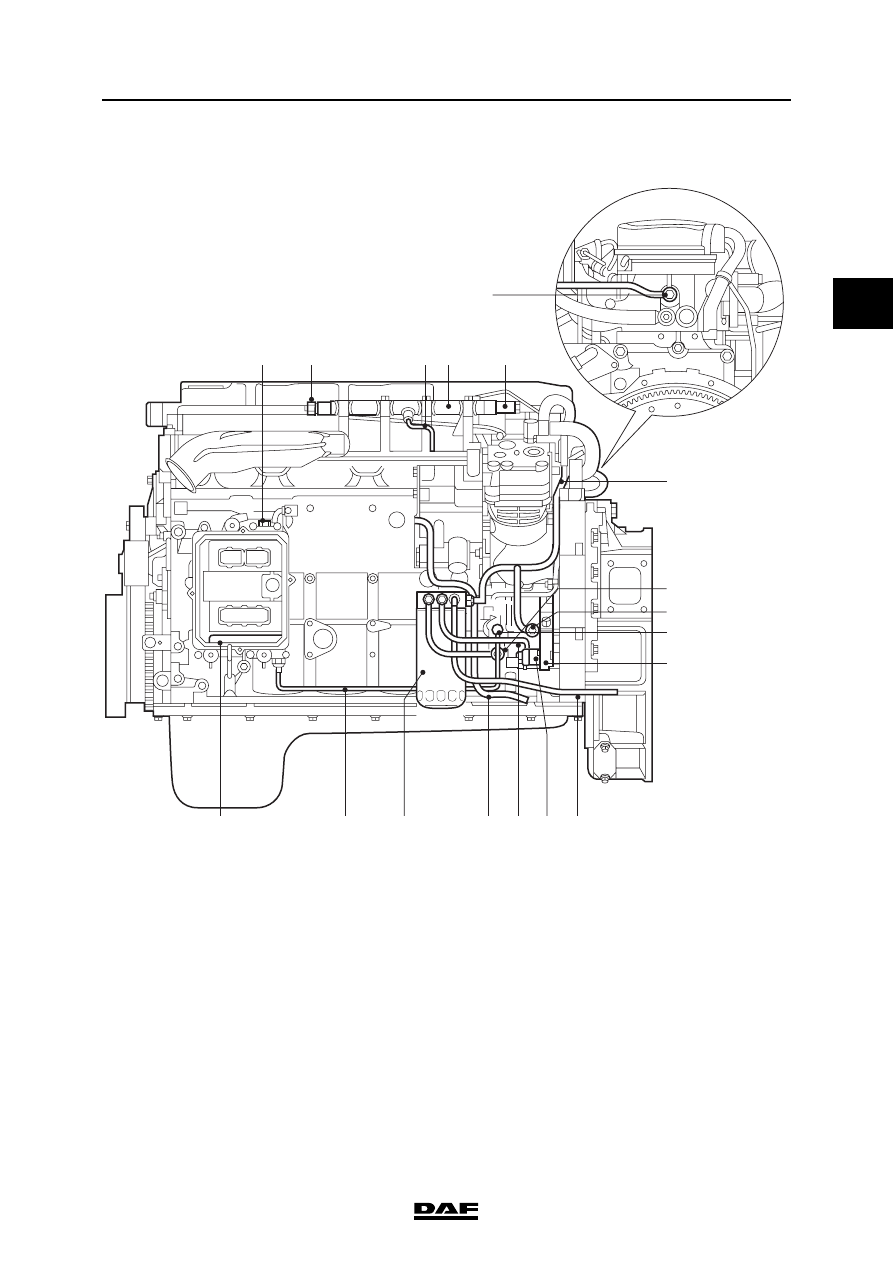

CE ENGINE FUEL SYSTEM

ΧΦ65/75/85 series

4

2

Location of components, production date

2003-49 (chassis number 0E628656)

1

2

3 4

5

6

7

11

13

17

18

16

10

9

8

i400872

14

15

12

|

|

|

© 200416 2-5 General CE ENGINE FUEL SYSTEM ΧΦ65/75/85 series 4 2 Location of components, production date 1 2 3 4 5 6 7 11 13 17 18 16 10 9 8 i400872 14 15 12 |