DAF CF65, CF75, CF85 Series . Manual - part 404

©

200416

4-1

PE engine fuel system

TECHNICAL DATA

ΧΦ65/75/85 series

4

0

4. PE ENGINE FUEL SYSTEM

4.1 GENERAL

Gallery pressure

Fuel level element

Overview of injectors

Fuel lift pump

Pump housing

At starting speed

approx. 0.5 - 1.0 bar

At idling speed

approx. 2.5 - 3.0 bar

At maximum no-load engine speed

approx. 6.5 - 7.0 bar

Angular displacement

86

Resistance rating

- Full

approx. 500

-

•

approx. 355

-

∂ approx.

234

-

approx. 137

- Not used

approx. 33

Underpressure valve opening pressure

10 - 20 mbar

Overpressure valve opening pressure

200 - 300 mbar

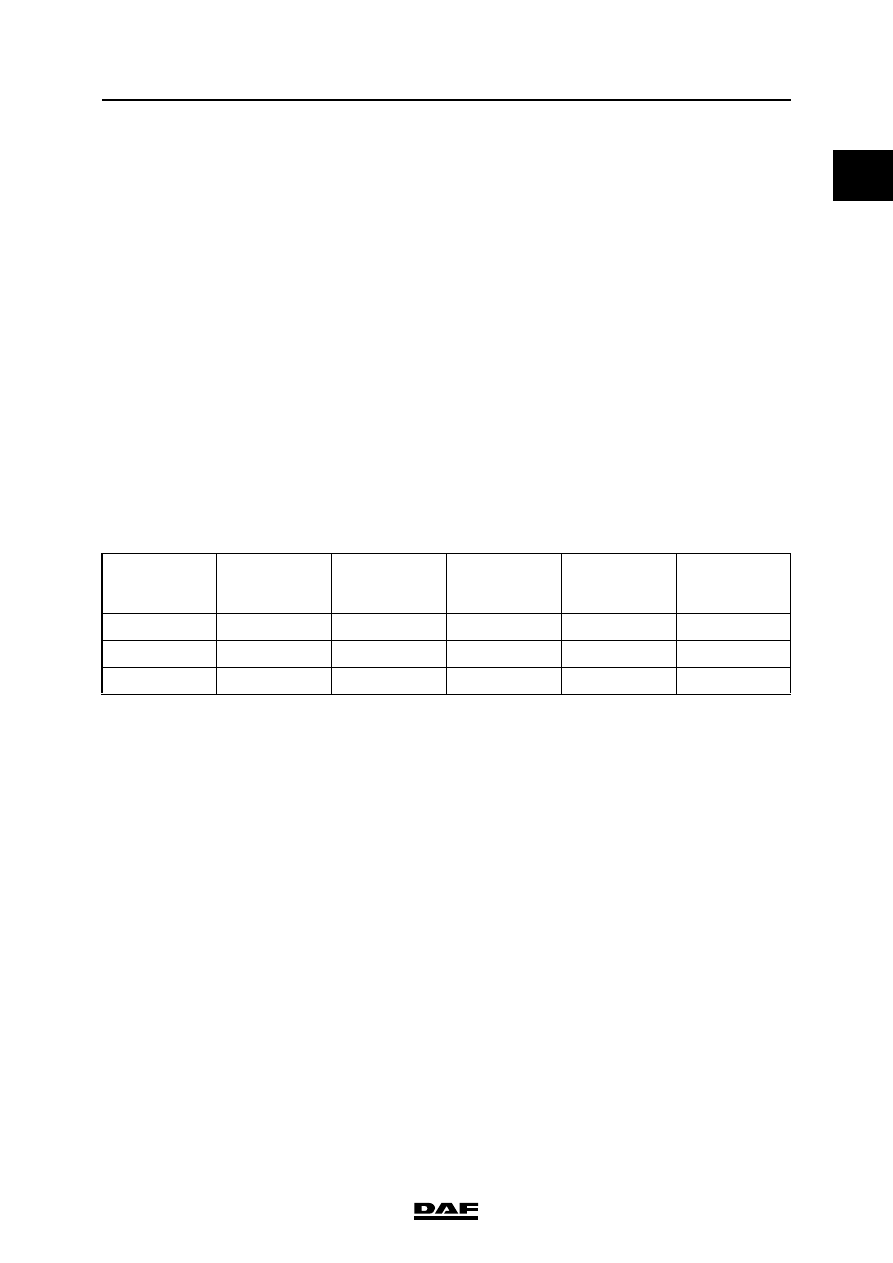

Engine type

Number of

holes in

injector

Nozzle no.

Hole diameter

Bar filter

Opening

pressure

PE 183 C1

8

1080

0,175

Yes

300 + 10 bar

PE 228 C

8

1080

0,175

Yes

300 + 10 bar

PE 265 C

8

1080

0,175

Yes

300 + 10 bar

Fuel lift pump pressure

7.0 - 8.0 bar

Pressure relief valve opening pressure

approx. 8.5 bar

Weight, including camshaft and pump units

approx. 70 kg

Pressure relief valve opening pressure

approx. 5.5 - 6 bar