DAF CF65, CF75, CF85 Series . Manual - part 252

©

200324

4-11

Removal and installation

XE ENGINE

CF65/75/85 series

2

8

Note:

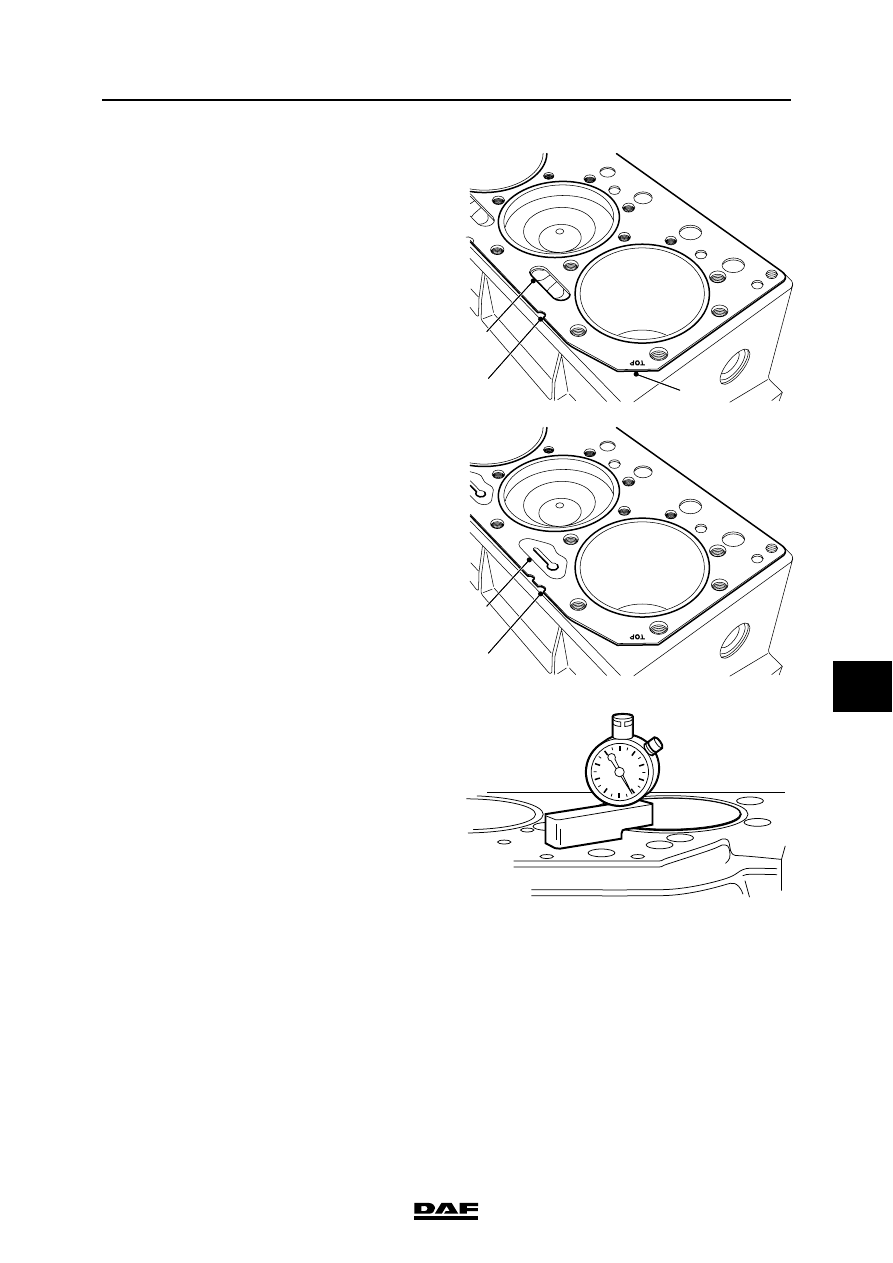

Note the markings (2, 5) on the cylinder head

gasket to be replaced and use the same gasket

when fitting. The cylinder head gaskets can also

be recognised from the coolant holes (3, 4).

22. Remove any remnants of gasket from the

cylinder heads and the cylinder block.

23. Check the sealing surfaces of the cylinder

block.

24. Check the threaded holes in the cylinder

block for damage and cracking.

25. Using the special tool (DAF no. 0694795),

check that the amount the cylinder liner

protrudes above the cylinder block is within

tolerance. See "Technical data".

26. Check the cylinder head. See "Inspection

and adjustment".

Installing the cylinder heads

1.

Clean the threaded holes in the cylinder

block using a screw tap.

Note:

Threaded holes not properly cleaned may

lead to too low a pre-tension of the cylinder

head bolts, causing leakage.

2.

Clean and degrease the sealing surfaces of

the cylinder heads and the cylinder block.

3.

Insert both guide pins (DAF no. 0694912)

into the threaded holes of the cylinder block.

M201278

3

2

1

4

5

M2 00 100