Content .. 1189 1190 1191 1192 ..

DAF CF65, CF75, CF85 Series . Manual - part 1191

©

200423

3-3

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΧΦ85 series

5

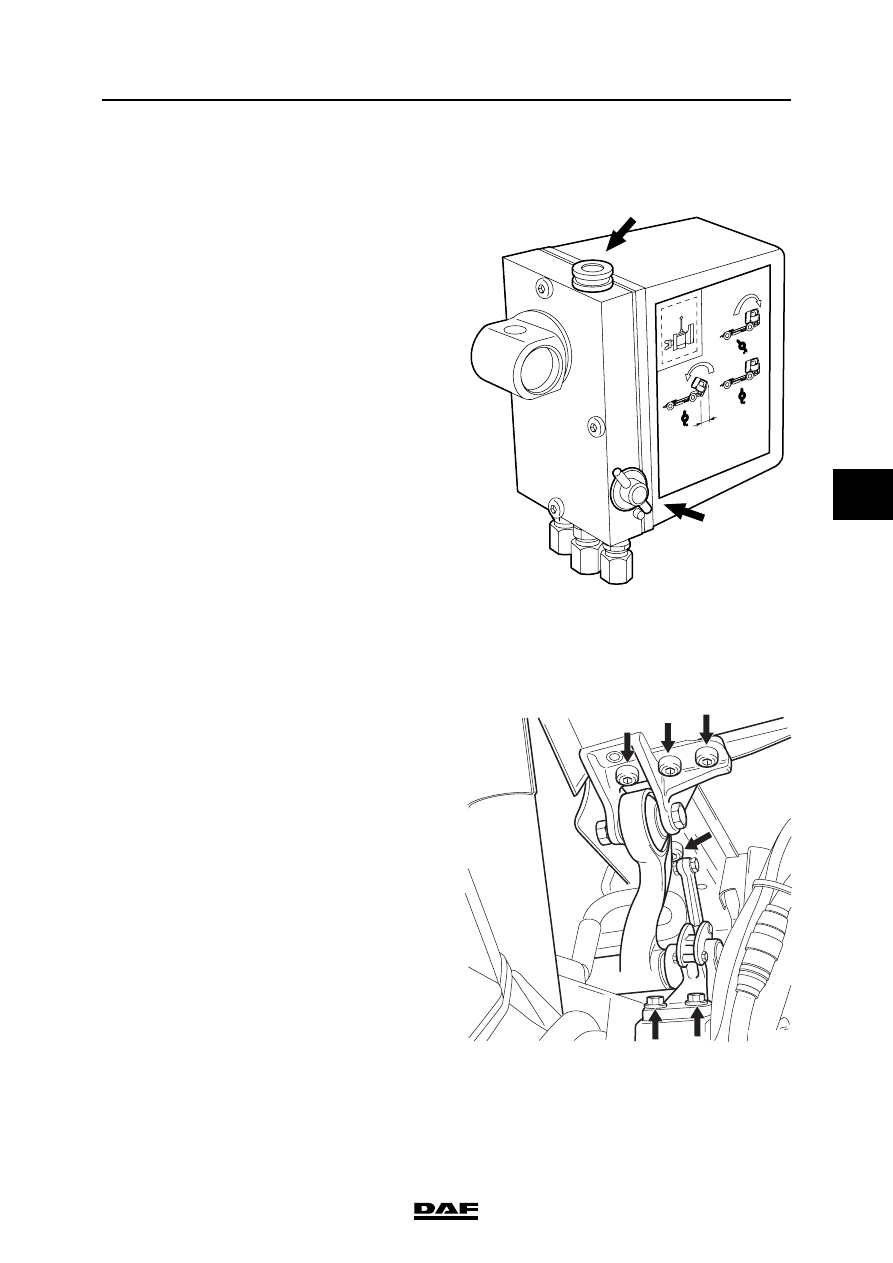

3.4 CHECKING THE FLUID LEVEL OF THE CAB TILTING PUMP

1.

The fluid level must be checked when the

cab is in the driving position.

2.

The cock (2) should be in the "tilting back"

position (anti-clockwise).

3.

Unscrew the filler plug (1) 3 to 4 turns. Wait

until the overpressure, if any, has left the

reservoir. Remove filler plug (1).

4.

Start pumping (maximum 5 pump strokes).

Ensure that the pump lever is in the lowest

position.

5.

Check the fluid level. This level should be no

more than 2 cm below the top of the filling

opening. Top up if necessary.

6.

Fit the filler plug (1) and hand tighten it.

3.5 CHECKING THE CAB FASTENING

1.

Check that all attachment bolts are in place.

2.

Visually inspect the attachment of the cab to

the tilting mechanism.

3.

Visually inspect the seals and condition of

the tilting mechanism.

Engine, cooling system and fuel system

M201062

N

!

1

2

K1 01 660