Content .. 1109 1110 1111 1112 ..

DAF CF65, CF75, CF85 Series . Manual - part 1111

©

200448

2-1

Inspection and adjustment

FAG

ΧΦ65/75/85 series

9

7

2. INSPECTION AND ADJUSTMENT

2.1 INSPECTION AND ADJUSTMENT, HEIGHT-CONTROL VALVE

1.

Measure the joint axle load of the leading

rear axle and the driven rear axle.

2.

Check the DAF number of the rear axle leaf

spring. The number is indicated on the front

of the leaf spring.

3.

Look up the axle load ratio of the vehicle

concerned. The axle load ratio is indicated

on the vehicle identification plate, fitted on

the left-hand side door post.

4.

Check the adjustment of the pressure-

limiting valve and adjust it if necessary.

5.

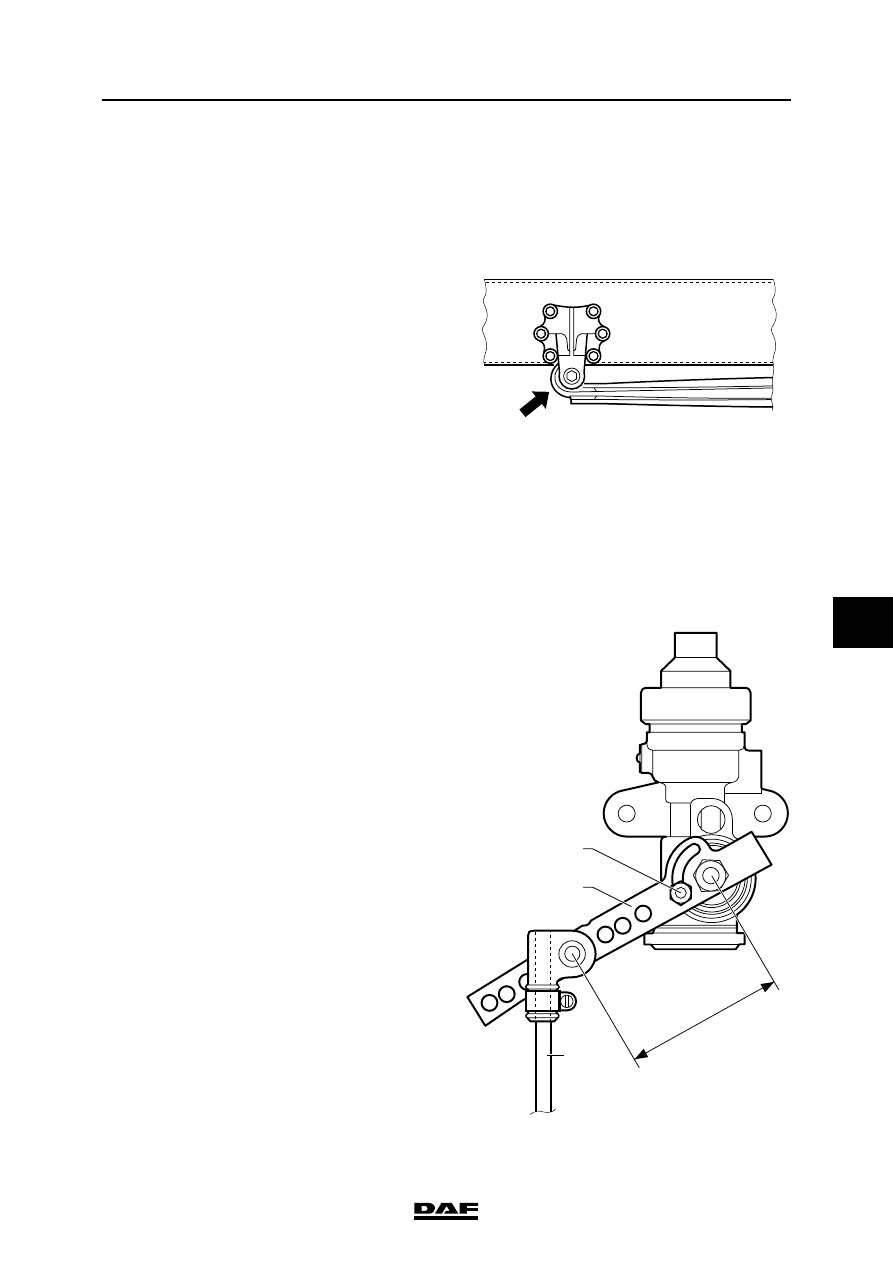

Check whether the bolt (A) is located in the

lower position of the slotted hole. Check

whether the bolt (A) is well tightened

6.

Measure the length l of the lever (B) and

check the lever length on the basis of the

value indicated in the table concerned, see

"Technical data". Adjust the lever length, if

necessary, to the length stated in the table.

7.

Fit a T-piece fitted with a test connection in

the pipe from the pressure-relief valve to the

air bellows.

8.

Connect a calibrated pressure gauge to the

test connection.

9.

Measure the bellows pressure. Look up in

the correct table, see "Technical data', the

relevant bellows pressure at the total axle

pressure measured and compare it with the

bellows pressure measured.

10. If the bellows pressure has to be adjusted,

the connection rod (C) between the lever and

the rear axle body must be extended or

shortened. Extending increases the pressure

and shortening decreases the pressure.

C9 00 436

A

B

C

l

W9 09 002