Content .. 1065 1066 1067 1068 ..

DAF CF65, CF75, CF85 Series . Manual - part 1067

©

200424

4-1

Removal and installation

HYDRAULIC LIFTING GEAR

ΧΦ65/75/85 series

8

9

4. REMOVAL AND INSTALLATION

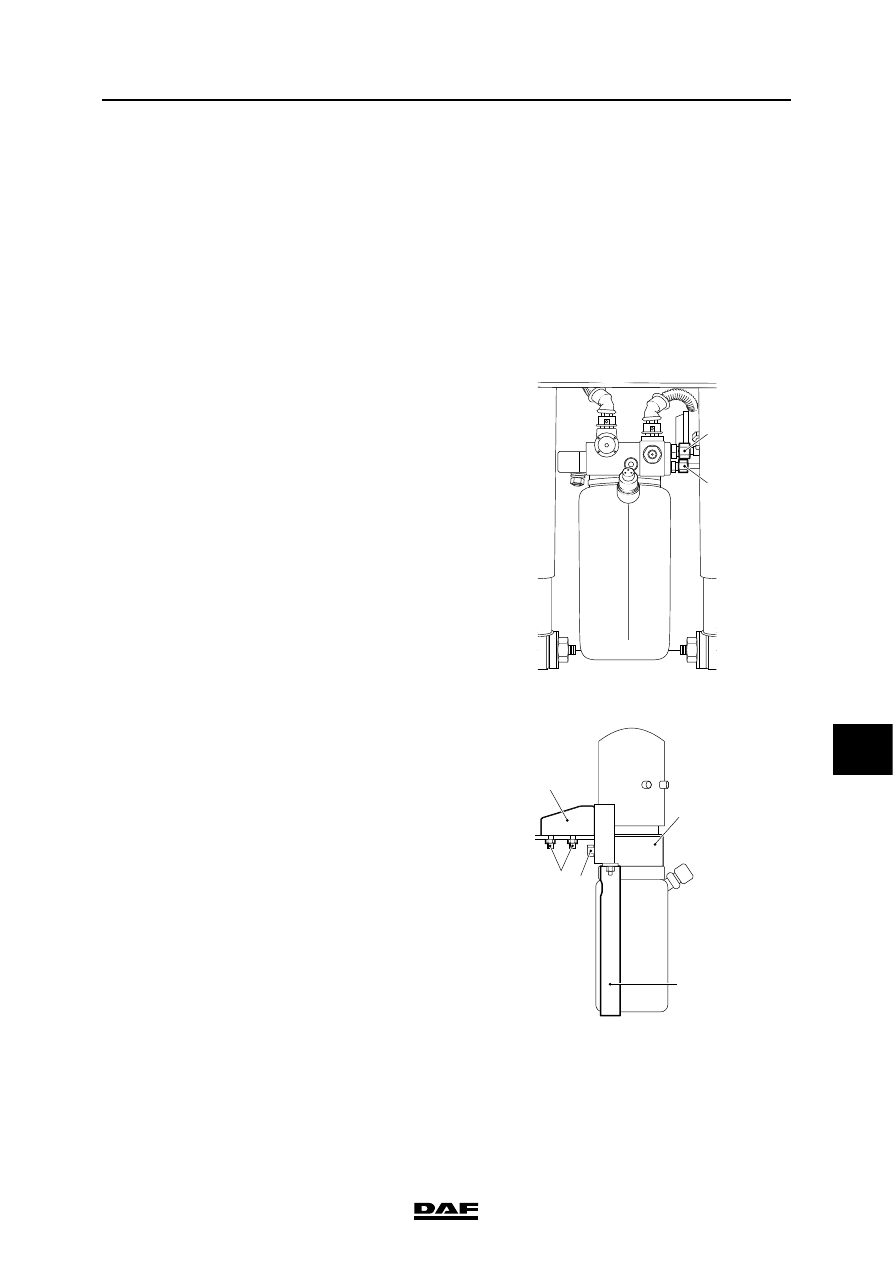

4.1 REMOVAL AND INSTALLATION, PUMP UNIT

Before removing components, the

component concerned and the pipe

connections should be cleaned.

Working conditions should be very

clean as even the smallest impurity

can cause faults.

Removing the pump unit

1.

The wheels of the trailing axle must rest on

the ground.

2.

Remove the fuse from the lifting gear.

3.

Mark the engine-wiring connection points

and disconnect these.

4.

Mark the solenoid valve connectors and

disconnect these.

5.

Remove the hydraulic lines from the pump

unit.

Note: the pipe attached to pipe connection A

may retain a residual pressure.

Wait for approx. 5 minutes after the trailing

axle has been lowered before disconnecting

the hydraulic lines from the pump unit.

Collect the oil coming from the pipe.

Plug the openings.

6.

Remove the bolts (5). Remove the

support (1) and the attached pump unit (2).

7.

Remove the bracket (3).

8.

Remove the two attachment bolts (4) and lift

the pump unit from the support (1).

9.

If a new pump unit is to be installed, the

position of line connections (A) and (B)

should be marked.

}

B

A

A8 00 281

1

2

3

4

5

A8 00 287