Content .. 1041 1042 1043 1044 ..

DAF CF65, CF75, CF85 Series . Manual - part 1043

©

200424

2-5

Inspection and adjustment

TANDEM REAR AXLE 1132T

ΧΦ65/75/85 series

8

6

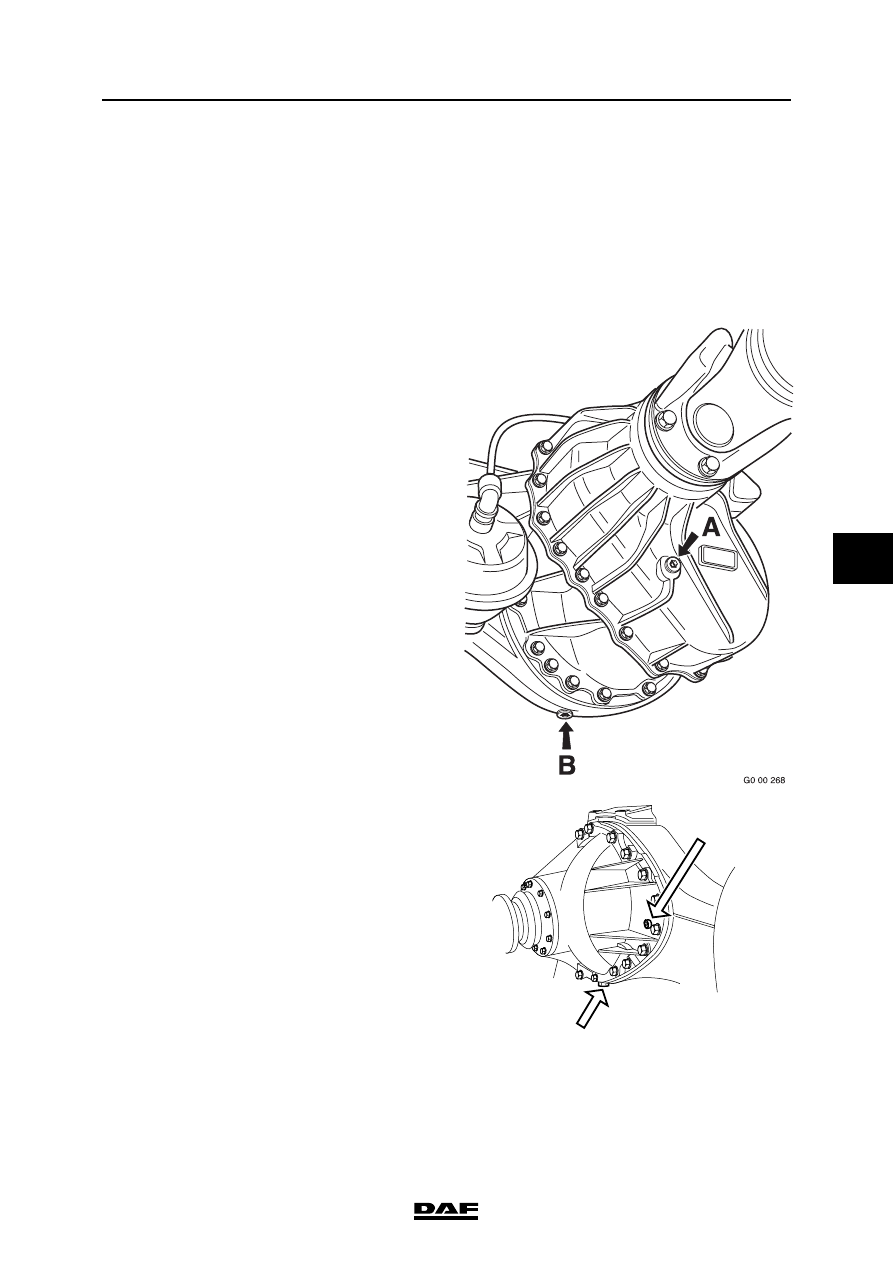

2.3 DRAINING AND FILLING, DIFFERENTIAL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

Checking the oil level, first axle

1.

Position the vehicle on a level surface.

2.

Remove the level check/filler plug (A). The

oil level should have reached the level

check/filler opening.

3.

Fit the level check/filler plug (A) using the

special Torx wrench (DAF no. 1329493) and

tighten to the specified torque; see

"Technical data".

Checking the oil level, second axle

1.

Position the vehicle on a level surface.

2.

Remove the level check/filler plug (A). The

oil level should have reached the level

check/filler opening.

3.

Fit the level check/filler plug (A) using the

special Torx wrench (DAF no. 1329493) and

tighten to the specified torque; see

"Technical data".

}

M8013

A

B