DAF XF105. Manual - part 102

1

©

200528

3-27

Control functions

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

3.13 ENGINE PROTECTION FUNCTIONS

The general task of this function is to limit the

requested quantity of fuel, related to the engine

speed, atmospheric pressure, coolant

temperature and other engine/vehicle conditions.

The controls ensure that the engine and drive

train are not mechanically and/or thermally

overloaded. The engine torque is limited or

reduced for this purpose. The protection

functions can be sub-divided into two groups:

-

Thermal engine protection

-

Mechanical engine protection

Thermal engine protection

1.

Cooling problem detection

2.

Over-heating protection

3.

Exhaust gas temperature limitation

Mechanical engine protection:

1.

Turbocharger protection

2.

Height correction

3.

PTO/engine speed control torque limiting

4.

Fuel temperature correction

5.

Engine oil pressure protection

6.

Engine speed protection when engine is cold

7.

Excess engine speed detection

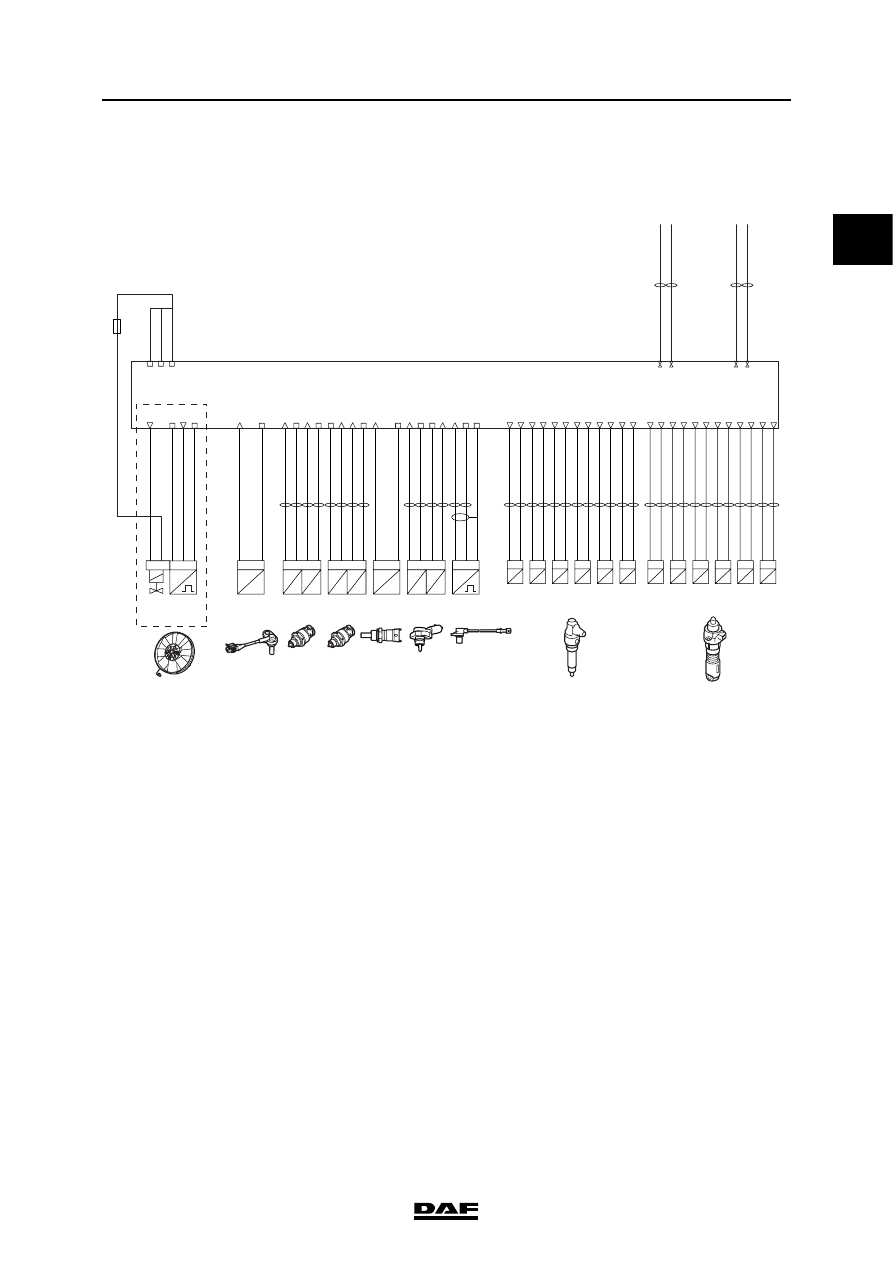

i401009

D965

1 2

high-side

low-side

Cyl.6

B136

1 2

high-side

low-side

Cyl.5

B135

1 2

high-side

low-side

Cyl.4

B134

1 2

high-side

low-side

Cyl.3

B133

1 2

high-side

low-side

Cyl.2

B132

A3

A7

A12

A23

A24

A15

A8

A19

A16

A4

A11

A20

1 2

high-side

low-side

Cyl.1

Pump units

B131

1 2

high-side

low-side

Cyl.6

B426

1 2

high-side

low-side

Cyl.5

B425

1 2

high-side

low-side

Cyl.4

B424

1 2

high-side

low-side

Cyl.3

B423

1 2

high-side

low-side

Cyl.2

B422

1 2

high-side

low-side

Cyl.1

Injectors

B421

4

pres.

F744

P

U

T

R

2 1

signal

3

signal

signal

ground

ground

oil

temp.

oil

temp.

F649

T

R

P

U

2 1

signal

ground

3 4

supply 5V

supply 5V

supply 5V

signal

shield

inlet

pres.

boost

4

pres.

F713

P

U

T

R

1 2

signal

3

signal

ground

fuel

temp.

fuel

N

5 1

supply 5V

signal

2

speed

fan

ground

T

R

1

signal

2

F566

F743

temp.

coolant

coolant

temp.

second

T

R

1

2

B335

oct.

fan

4

3

ground

signal

C16

C31

C36

C35

supply

supply

supply

C60

C61

C62

Vehicle

CAN2

low

Vehicle

CAN2

high

F

N

2 1

signal

return

3

F552

speed

crankshaft

A2

A8

A9

A22

A21

A14

A5

A18

A13

A1

A10

A17

C26

A34

A46

C25

A45

A41

C34

A42

C30

C29

C33

A38

A37

A27

A28

A30

A49

A50

A60

CAN2 low

CAN2 high

B53

B45

Vehicle

CAN1

low

Vehicle

CAN1

high

CAN1 low

CAN1 high

B35

B27