DAF XF105. Manual - part 100

1

©

200528

3-19

Control functions

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

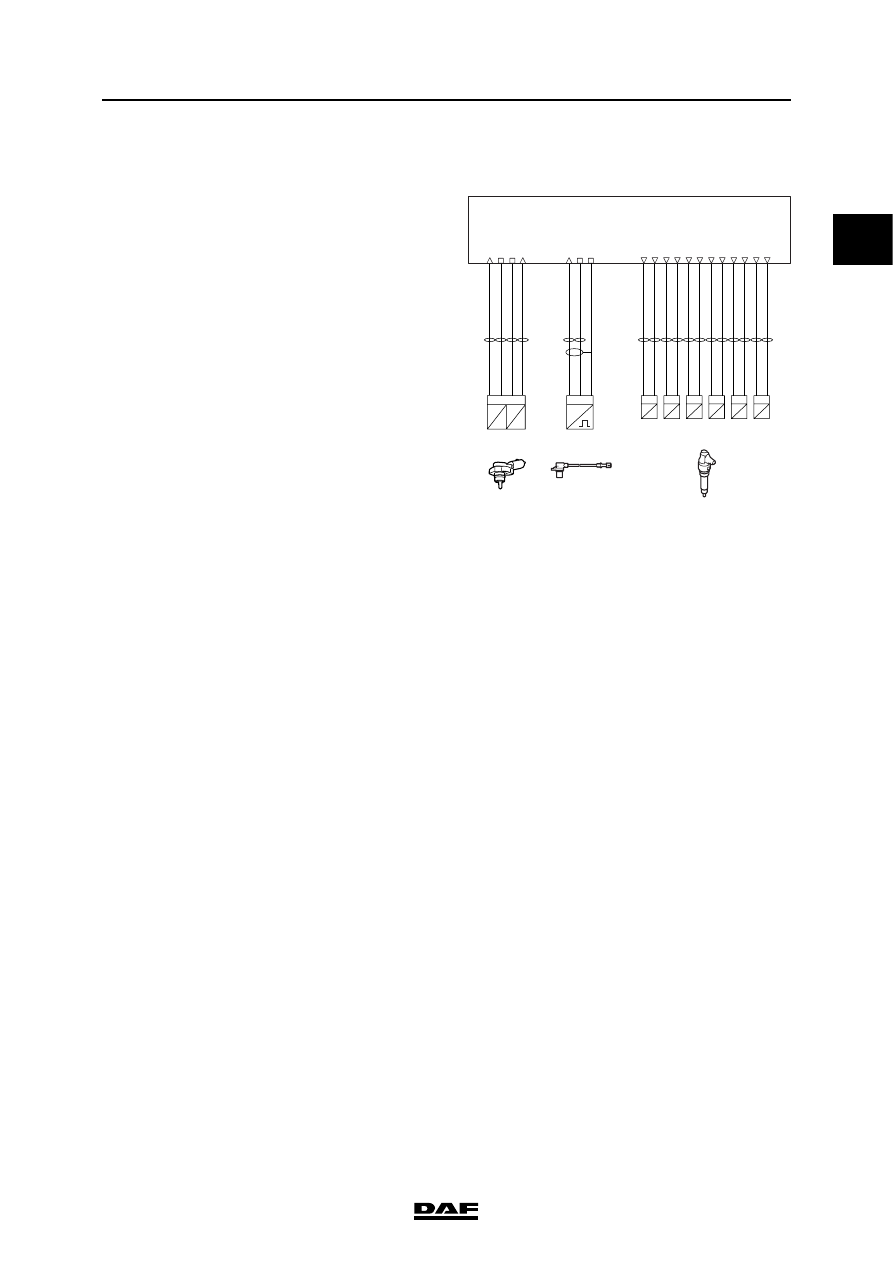

3.10 SMOKE LIMITATION

This function ensures that emissions of black

smoke are kept to a minimum level. The fuel-air

ratio is responsible for the development of

smoke. The DMCI electronic unit calculates

smoke limiting on the basis of the inlet air

pressure (F649, pin A34) that is compensated by

the inlet air temperature (F649, pin A30). To

calculate the mass of the intake air, the electronic

unit requires the inlet air temperature, the inlet air

pressure and the intake air volume. The latter can

be calculated on the basis of the cubic capacity

and the speed of the engine. When the intake air

mass has been calculated, the electronic unit can

determine the maximum amount of fuel that can

be injected to prevent excessive development of

smoke.

If the inlet air boost pressure signal is absent or is

not correct, the electronic unit carries out

calculations using an air mass table based on the

engine speed (F552).

Relevant components

-

Charge boost pressure and temperature

sensor (F649)

-

Crankshaft sensor (F552)

-

Injectors (B421 to B426)

i401000

D965

1 2

high-side

low-side

Cyl.6

B426

1 2

high-side

low-side

Cyl.5

B425

1 2

high-side

low-side

Cyl.4

B424

1 2

high-side

low-side

Cyl.3

B423

1 2

high-side

low-side

Cyl.2

B422

1 2

high-side

low-side

Cyl.1

Injectors

B421

temp.

F649

T

R

P

U

2 1

signal

ground

3 4

supply 5V

signal

inlet

pres.

boost

N

2 1

signal

return

shield

3

F552

speed

crankshaft

A2

A8

A9

A22

A21

A14

A5

A18

A13

A1

A10

A17

A34

A27

A28

A30

A49

A50

A60