Chery Tiggo 5 (T21). Manual - part 209

18–

25

18

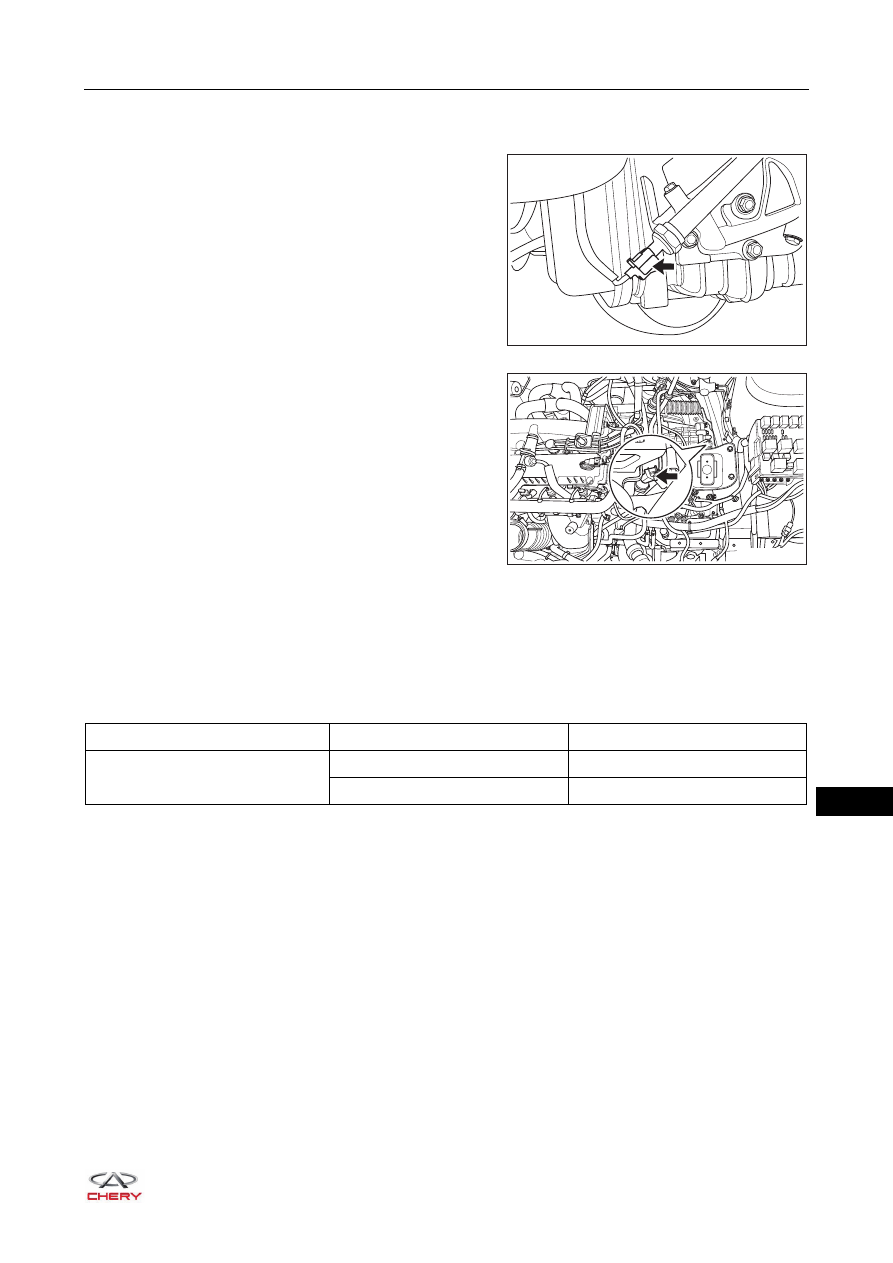

Primary/Secondary Shaft Pressure Sensor Inspection

1. Turn off all the electrical devices and ignition switch.

2. Disconnect the primary/secondary shaft pressure sensor

connector.

3. Check for resistance between the terminals of primary/secondary shaft pressure sensor as shown in the

table below at normal temperature.

HINT:

The inner parts of the sensor are triode and capacitor, and will be affected greatly by the environment and the

usage condition. Therefore, the actual measured value is within the specified value plus/minus 15% in the

table below.

RT21180280

RT21180290

Item

Multimeter Connection

Specified Condition (KΩ)

Primary/Secondary Shaft Pressure

Sensor

1 - 3

45.77

2 - 1

10.06