Chery Tiggo 5 (T21). Manual - part 208

18–

21

18

DIAGNOSIS & TESTING

Transmission Fluid Level and Quality Inspection

1. After the vehicle runs for 5 min, the temperature will reach the normal working conditions (ATF temperature

60 - 80°C, and the engine coolant temperature 80 - 100°C).

2. Park the vehicle on a flat ground and pull the parking brake lever.

3. Start up the engine to make it run at idle speed, and then fully depress the brake pedal and move the shift

lever for five times at each gear. Finally, place the lever at "P" or "N" position.

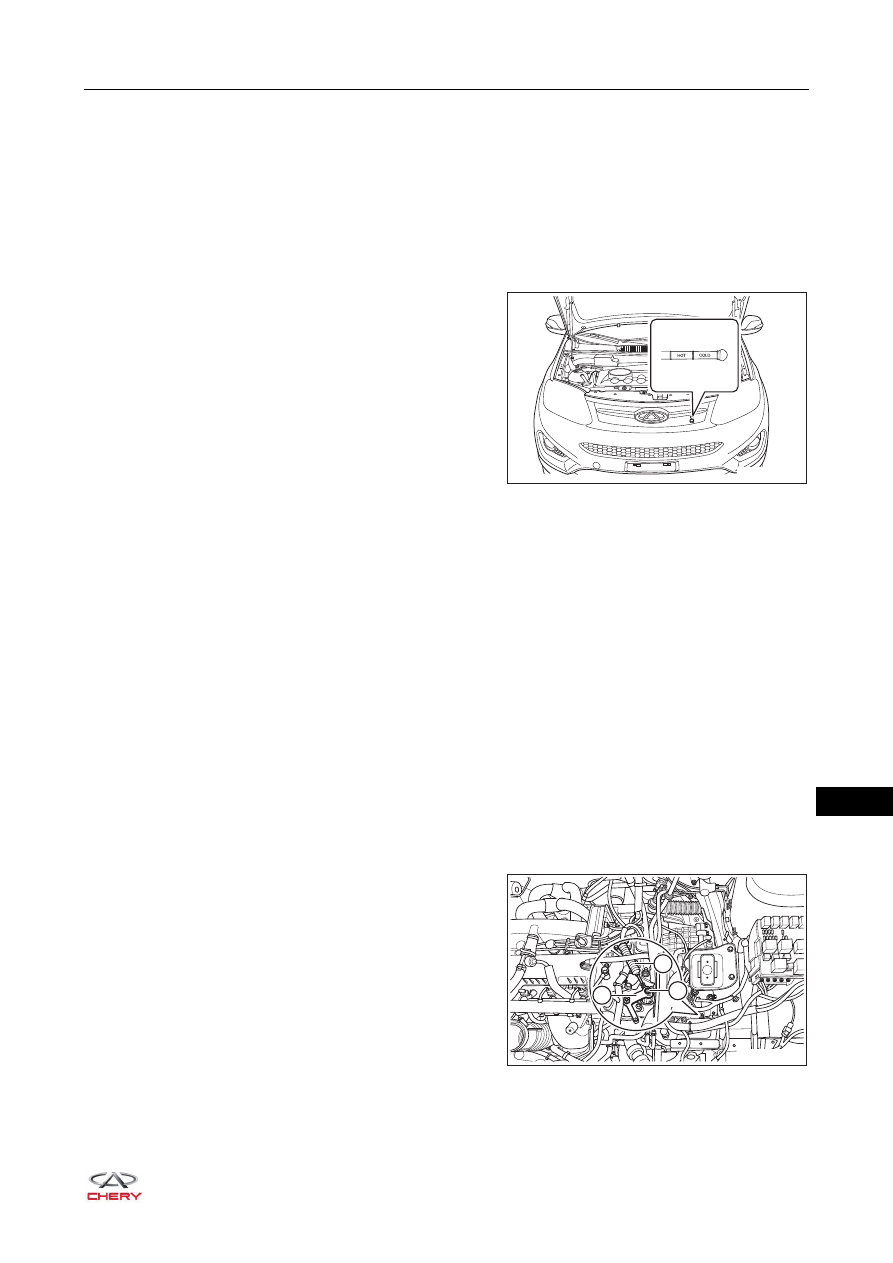

4. Pull out the automatic transmission fluid dipstick and

clean it with non-wool paper; then insert the dipstick into

the filling pipe as much as possible and then take out to

observe whether it reaches the "HOT" position.

5. Check the transmission fluid:

If the fluid becomes brown, replace the automatic transmission fluid and check the vehicle for working

conditions.

If the fluid becomes milk white or cloudy, or there is water in the fluid, replace the automatic transmission

fluid and check for the leaking location.

If the fluid becomes black with a lot of powders and there is abnormal wear in the CVT, replace the

automatic transmission fluid and check the vehicle for normal working.

Gear Shift Cable Inspection and Adjustment

Shift the gear lever from "N" gear to other gears to check whether the lever can be shifted to other gears

smoothly and precisely, and also check whether the gear indicators can indicate the gear correctly.

If the gear indicators indicate incorrectly, adjust them as shown below:

1. Park the vehicle at a safe place and pull the parking brake lever.

2. Change the shift lever to the "N" position.

3. Turn off all the electrical devices and ignition switch.

4. Disconnect the negative battery cable.

5. Remove the battery, battery tray and tray bracket (

).

6. Remove the connecting nut (3) of the gear shift cable (1)

and shift arm (2). Disconnect the gear shift cable from the

shift arm.

RT21180200

RT21180210

1

3

2