Chery Tiggo 5 (T21). Manual - part 204

18–

5

18

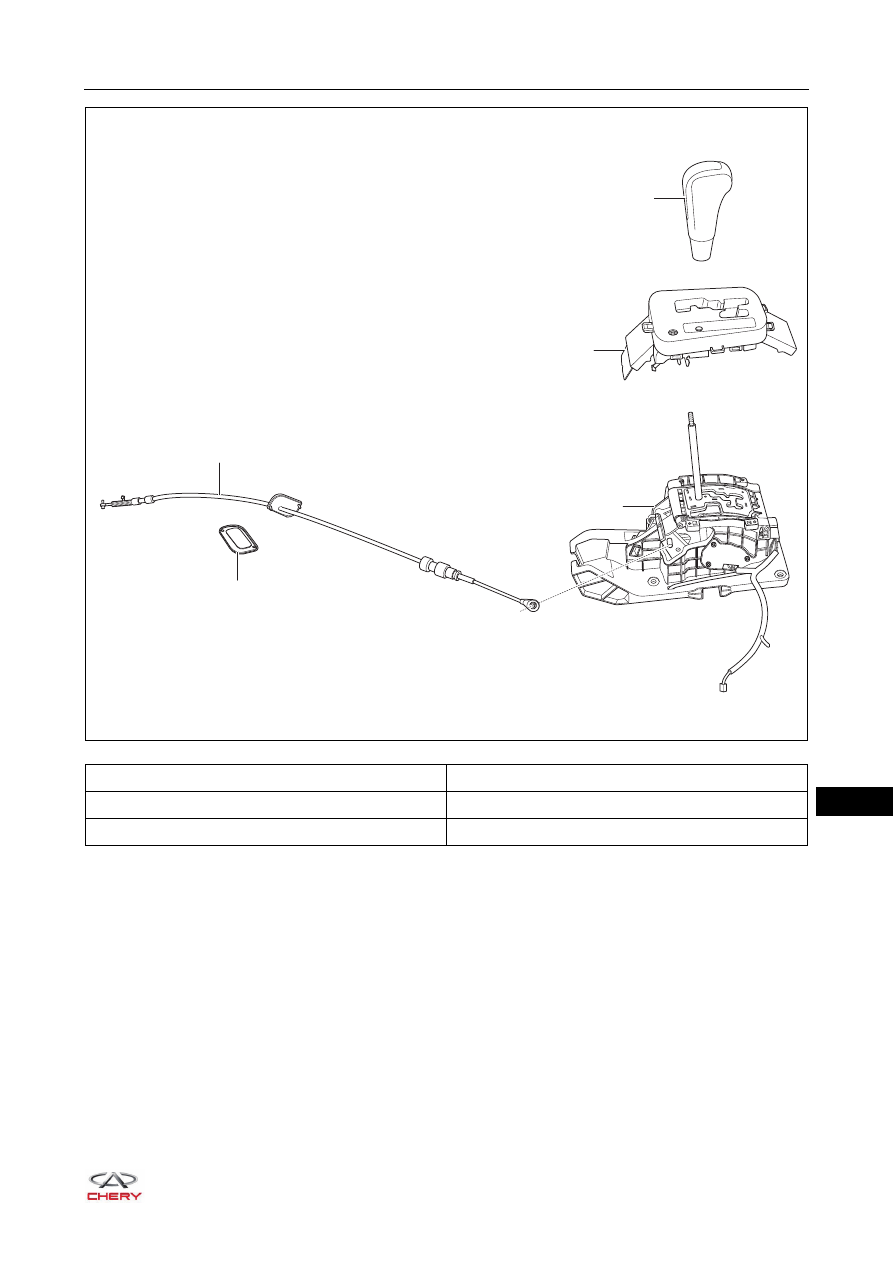

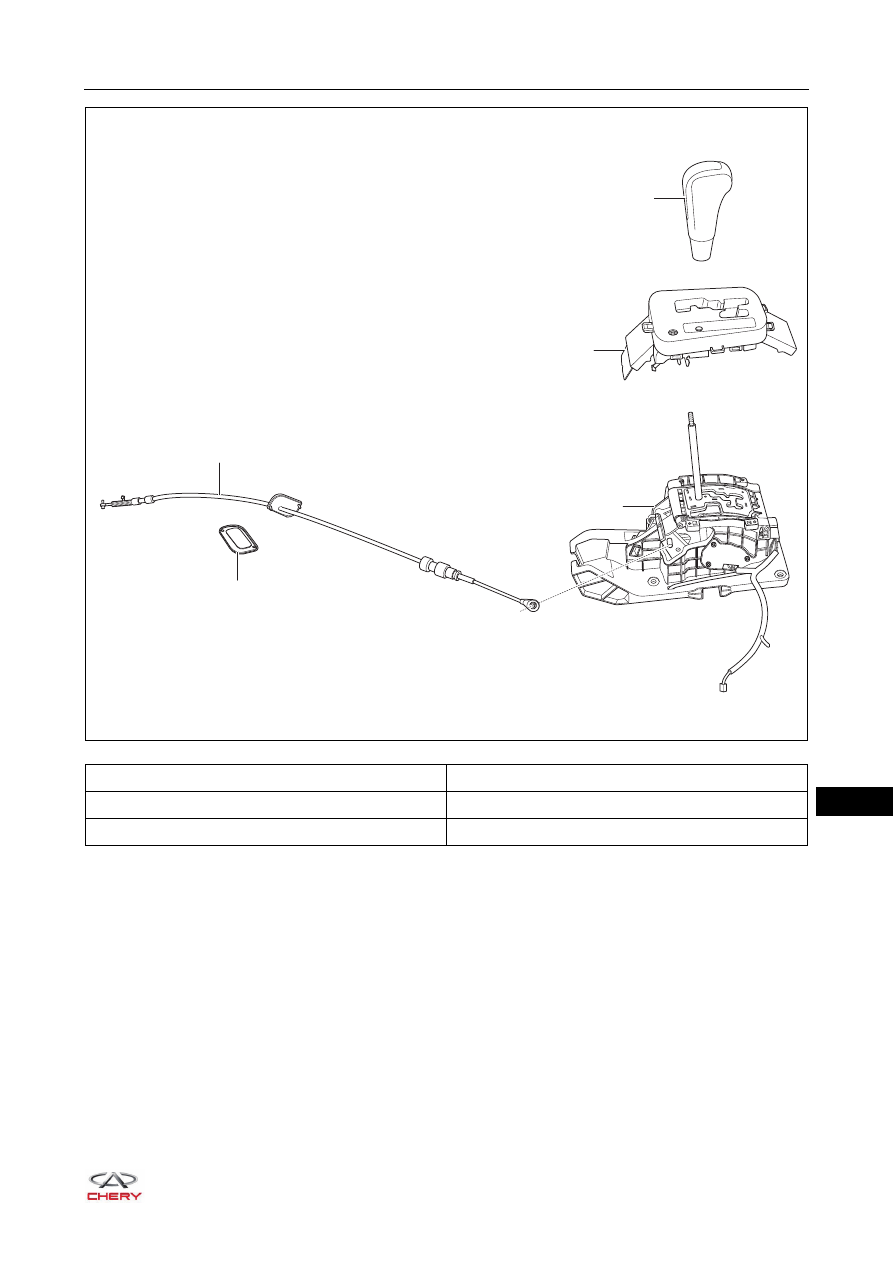

1 - Gear Shift Cable

2 - Gear Shift Lever Knob

3 - Gear Indicator Panel

4 - Gear Shift Control Mechanism

5 - Gear Shift Cable Dust Boot

2

3

4

5

1

RT21180020

|

|

|

18– 5 18 1 - Gear Shift Cable 2 - Gear Shift Lever Knob 3 - Gear Indicator Panel 4 - Gear Shift Control Mechanism 5 - Gear Shift Cable Dust Boot 2 3 4 5 1 RT21180020 |