Chery Tiggo 5 (T21). Manual - part 125

07–

86

07

40.Remove the crankshaft main bearing shell.

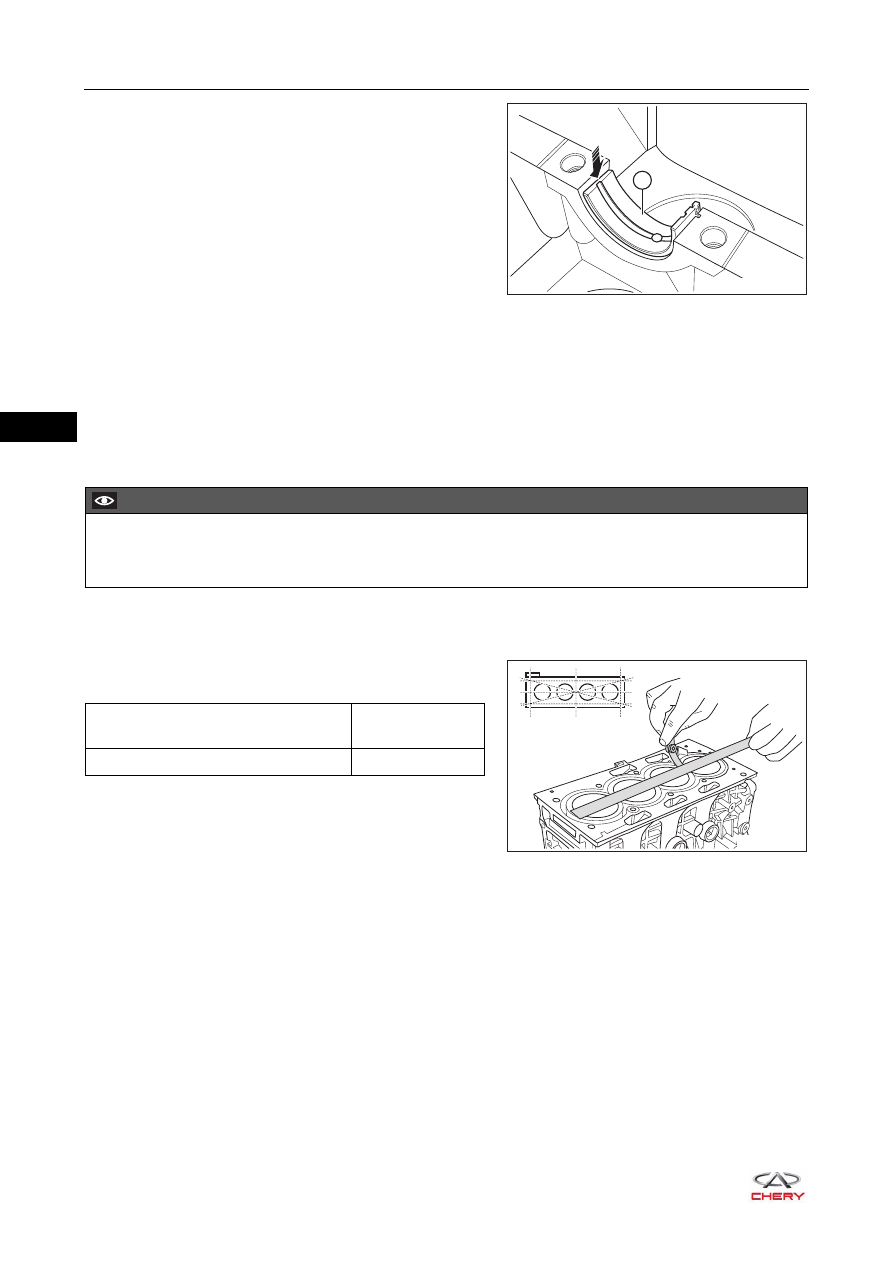

a. Slightly push the crankshaft main bearing upper shell

(1) in the direction of arrow and remove it carefully.

HINT:

Remove other crankshaft main bearing upper

shells from the cylinder block in the same way.

Remove the crankshaft main bearing lower shells

from the crankshaft frame in the same way.

Pay attention to the notch position. Push out the

bearing shell carefully as shown in the illustration.

It is difficult to push out the bearing shell and the

parts may be damaged if pushing in the opposite

direction.

Inspection

1. Check cylinder block.

Clean engine block thoroughly and check all hole passages for leakage.

Check engine block and cylinder bore for cracks.

Check bottom surface of engine block for cracks.

2. Check flatness of engine block upper surface.

a. Clean the engine block upper surface.

b. Using a precision ruler and feeler gauge, measure the

flatness of engine block upper surface.

It is not allowed to grind the block upper surface. If the

flatness of engine block upper surface exceeds the

limit, replace the engine block.

3. Check cylinder.

a. Cylinder cylindricity and roundness calculation method (for general measurement):

Thrust direction - perpendicular to the axis of crankshaft; Axial direction: Parallel with the axis of

crankshaft

Cylindricity calculation method

Cylindricity is half of the diameter difference measured in the same direction.

Cylindricity in thrust direction = (maximum diameter measured at A, B and C in thrust direction -

minimum diameter measured at A, B and C in thrust direction)/2

Cylindricity in axial direction = (maximum bore diameter measured at A, B and C in axial direction -

minimum bore diameter measured at A, B and C in axial direction)/2

Compare the maximum value measured at the 2 directions with the standard cylinder cylindricity.

Roundness calculation method

1

RT21071020

CAUTION

DO NOT wash the cylinder at high temperature. Otherwise the cylinder liner will stick out beyond the

engine block.

RT21071030

Measurement Item

Specification

(mm)

Engine Block Upper Surface Flatness

0.04