Chery SQR 7160 sedan. Manual - part 118

●Measuring Method

a ohmmeter method

Measure resistance with an ohmmeter, and determine if water temperature sensor operates

upon measured engine coolant temperature and below diagram. Remove coolant

temperature sensor, immerse into water and heat water. The sensor has different resistance

at corresponding temperature.

Water Temperature Sensor Resistance Specification

Temperature(℃)

Resistance(Ω)

Temp.(℃)

Resistance(Ω) Temp.(℃)

Resistance(

-40 100865

25

2795

90

241.8

-35 72437

30

2240

95

207.1

-30 52594

35

1806

100

178.0

-25 38583

40

1465

105

153.6

-20 28582

45

1195

110

133.1

-15 21317

50

980

115

115.7

-10 16120

55

809

120

100.9

-5 12261

60

671

125

88.3

0 9399

65

559

130

77.5

5 7263

70

469

135

68.3

10 5658

75

395

140

60.3

15 4441

80

334

145

53.4

20 3511

85

283

150

47.5

b voltmeter method

Install the sensor on the motor, and crank engine. Connect sensor signal lead to

voltmeter, there are different voltage drop at different temperature.

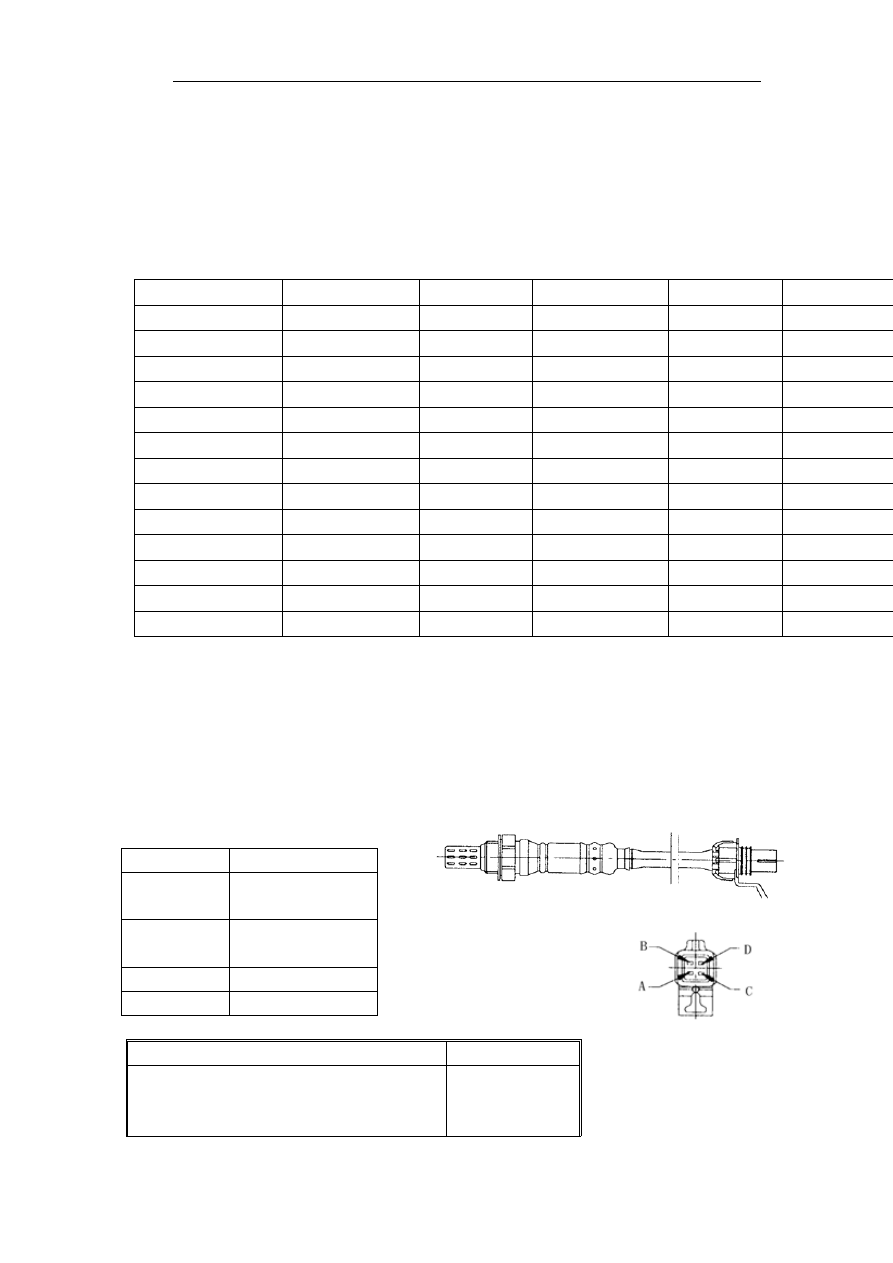

Oxygen sensor

Oxygen sensor is installed on exhaust pipe and accurately regulate excess air co-efficiency .

Oxygen sensor has 4 leads: C. voltage lead (pin A16) B. signal lead (pin B1)

A. signal ground (pin B23) D heater ground (pin B16)

PIN Function

C Sensor

voltage lead

B Sensor

signal

output

A Signal

ground

D Heater

ground

Oxygen sensor heater resistance impedance specification table

when temperature is 23℃, impedance is

13.2+/-10%

Resistance Heat Co-efficiency of

impedance

(23-800℃) (ppm/℃)

1150