Chery SQR 7160 sedan. Manual - part 114

CHERY AUTOMOBILE CO., LTD Automatic Transmission Fault Diagnosis Manual

166

depth is determined

the

uter racer and the

case plane is 10.2mm. The distance

from the odometer drive gear case

to the bolt hole surface is 8.65mm.

The washer is 1.65mm thick;

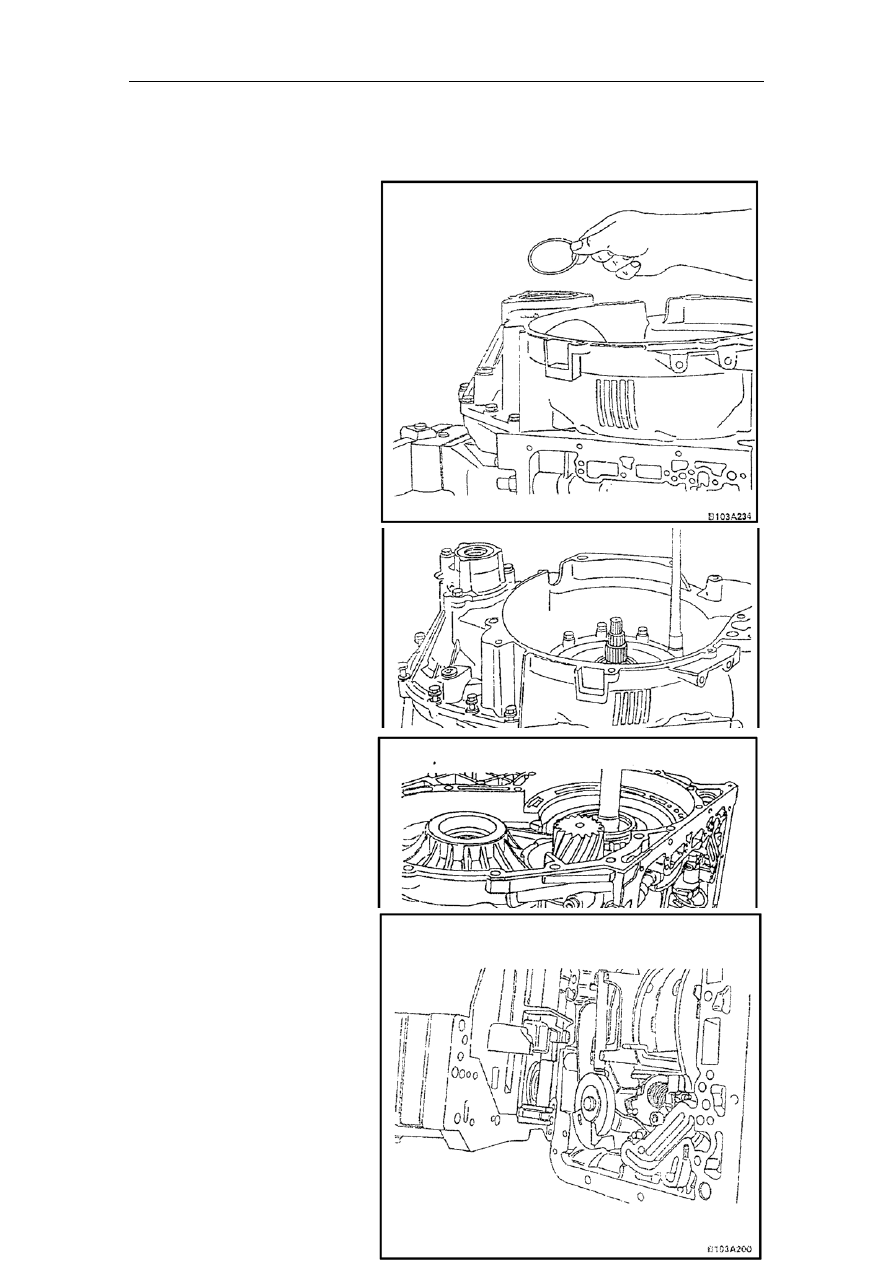

63. Install the converter case and

washer and fix them with bolts:

The bolts’ tightening torque:

23Nm

64. Use the transmission fluid to

lubricate clutch B drum.

Tighten the adjusting bolt on

the brake band with a

tightening torque of 10Nm.

Note: Rotate clutch B drum while

tightening the brake band to ensure

that it is installed to the correct

position;

65. Turn the adjusting bolt

counterclockwise by 3mm.

Note: The gap between the

adjusting bolt and brake band is

.9mm~1.2mm;

62. In accordance with the measurements, install one or two washers between the differential and

the odometer drive gear case. Adopt the combination of different depths in order to get the

most approximate value. The

washer’s

by the following formula:

S=A-B+0.1mm

For example: The distance between

bearing’s o

The washer’s thickness is S:

S=10.2-8.65+0.1=1.65mm;

0