Chery SQR 7160 sedan. Manual - part 47

CAC Gasoline Engine Maintenance And Servicing Manual

106

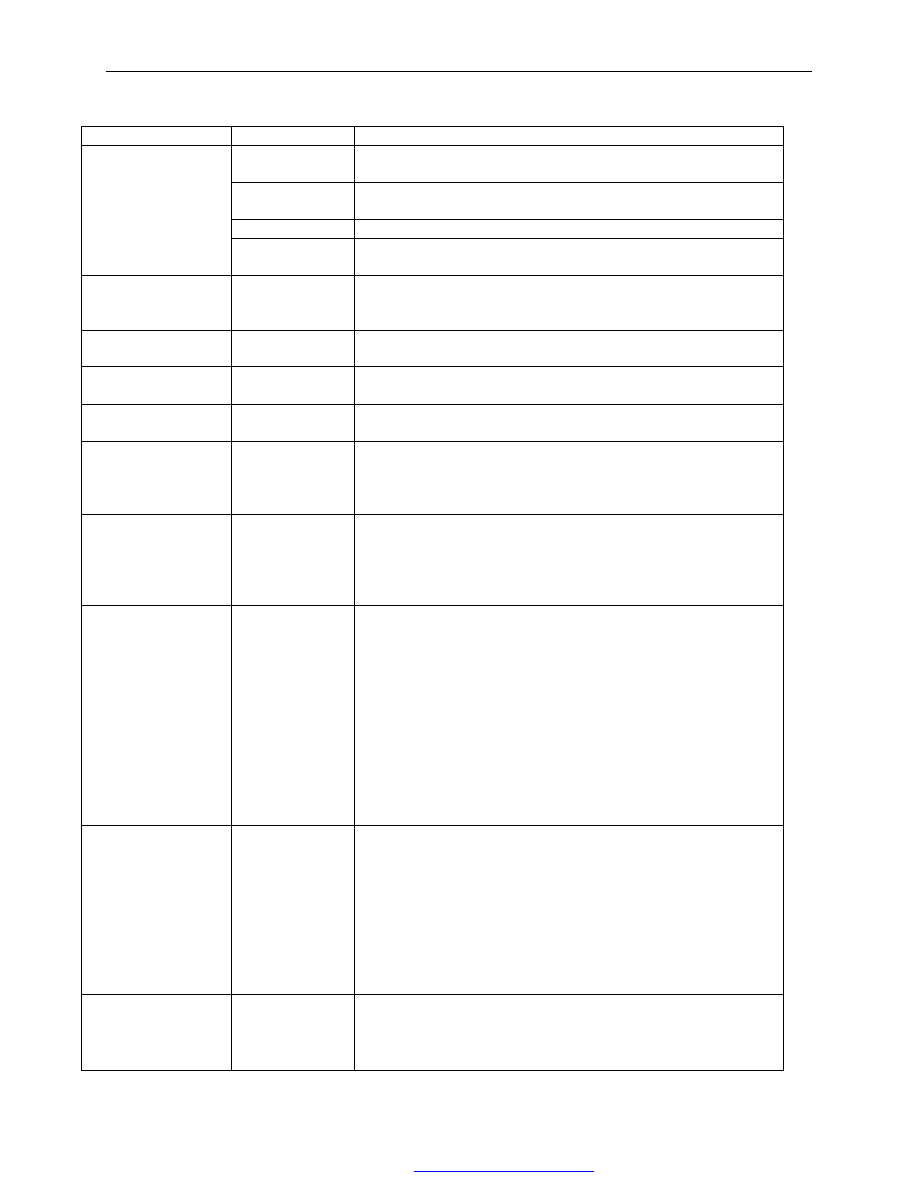

5.malfaction, cause and correction

Malfuction

cause

Correction

Fuel pump. fuel

injector IVM523

check for operation by CHECK—UP1

Tachometer

senser.

Check wring, sensor resistance and installation of the sensor.

Dual relays

Check for function, connector connection and blown fuse.

Vehicle cannot start

35——pin

connection

Check for the wiring connection to ECU.

Difficult to start;

idling speed too

high or too low

Engine

idling

speed

control

solenoid.

check for solenoid operation and 4—pin connection by

CHECK—UP1.

warning light on

During idling,

λsensor

Check for the wiring, proper sensor tightening torque and the

sensor heater’s operation

warning light on for

a long time

Diagnosis

warning light

Check for the signal wiring grounding.

warning light

doesn’t turn on

Diagnosis

warning light

The bulb is broken or circuit is open

Rough idling at high

temperature.

Throttle

valve

sensor or water

temperature

sensor

the throttle valve opening angle and water temperature signal

displayed by CHECK—UP1 should match the engine operation.

Rough idling at low

temperature.

coolant

temperature

sensor or intake

air temperature

sensor

The temperature indicated should be in the vicinity of the

ambient temperature.

Idle intermittent

wave

1—throttle

valve body

30MM4

1.check the throttle valve cable for proper adjustment, smooth

movement.

2.if the throttle valve cable is correctly adjusted and may move

smoothly, remove it. Check the throttle valve for resistance by

turning it with a hand (for friction);

3.display the throttle valve position by CHECK—UP1. If both 1

and 2 are correct and engine speed is still high , while

CHECK—UP1 displays “angle is greater than the allowable

angle”, then the malfunction is positively determined. It is

necessary to replace the throttle valve potentiometer. If the angle

is within the specified range, sensor wiring and connector should

be checked.

Idling speed

fluctuates

continuously at high

temperature.

1.throttle valve

body

1.2 seal

1.3

vacuum

connection

1. check the above item 1,2,3 for intermittent idling speed

functions;

1.2 check the seal between cylinder head and throttle valve body;

1.3check the vacuum lines to the two vacuum passages,

which are of absolute pressure. check the fuel vapor

recirculation

passages, which are connected to the throttle

valve body and intake manifold.

Check the vacuum tube sealing in intake manifold for brake

servo .

Vehicle performance

deteriorates

1—fuel supply

system

1. Check for fuel supply. If fuel pressure is 1±0.1bar, it is ok;

2. If malfunction still remains after upper throttle body

(30mm12) is replaced, with a pressure regulator in the upper

throttle body, check fuel filter and fuel pipes.