Chery SQR 7160 sedan. Manual - part 19

Usage, repair and maintenance specification of CAC gasoline engine

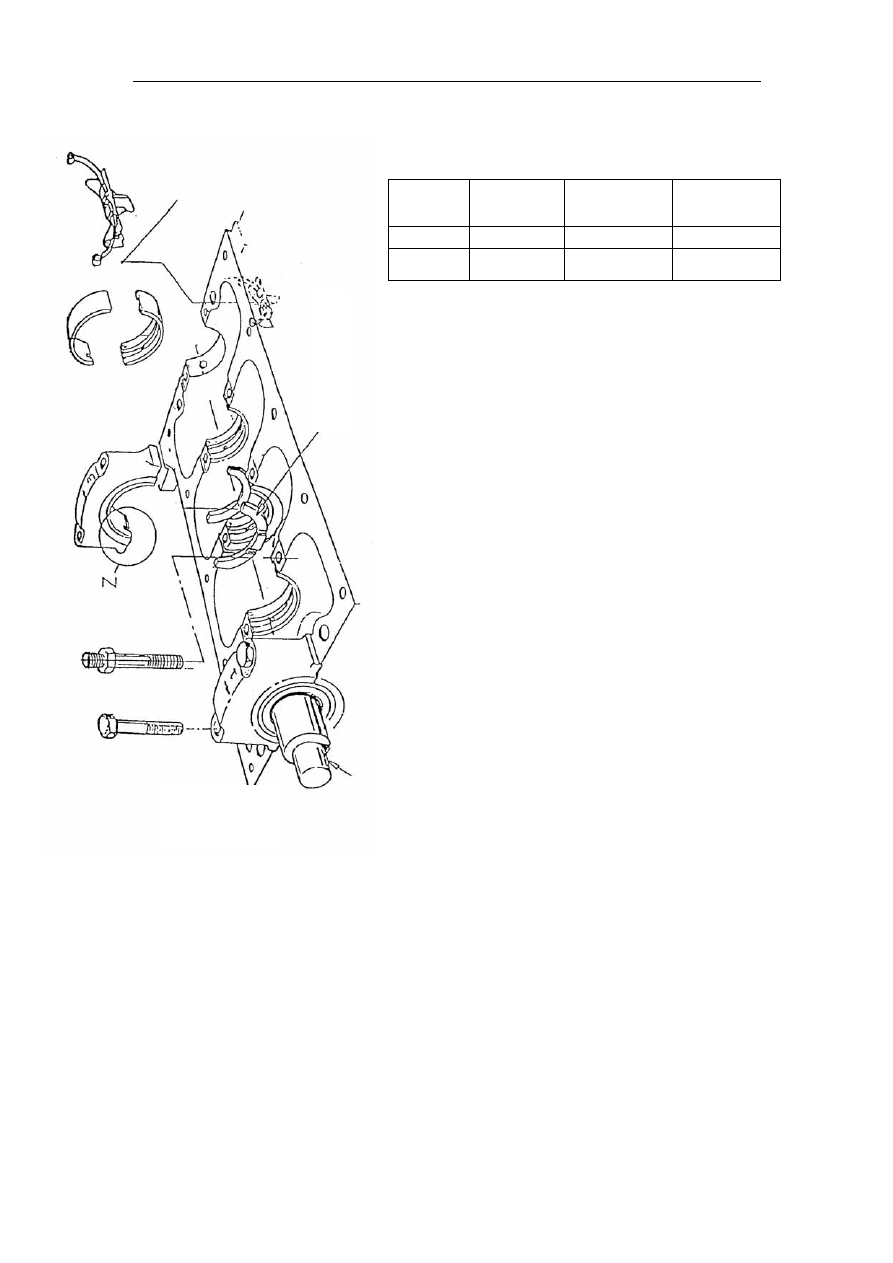

—the size of crankshaft thrust, thrust washer and cylinder

block thrust: unit:mm

Fig. 68

T

w

o thrus

t pieces

level

The size of

cylinder body

thrust

The size of

crankshaft thrust

The thickness of

thrust washer

standard

24±0.03 28.825—28.875 2.326±0.025

oversize

0.38

24±0.03 29.205—29.255 2.516±0.025

Installation:

——Before installation, use the second screw tap taps the

threaded hole in cylinder body, especially the threaded

hole of cylinder head bolt and main bearing bolt.

The threads of cylinder head bolt is M10×1.5—6H,

the threaded hole of main bearing bolt is M12×1.75—

6H。

——The installation of crankshaft woodruff key

Drive the semicircular key into key groove lightly.

The magnitude of interference for key and key groove is

0.00—0.051mm。After the semicircular key is installed,

check the protrusion height. It should be 1.392 —

1.739mm.

——Crankshaft thrust washers are two pieces. They are

only installed on the front and back thrust surface of

cylinder block.

Before installation, apply the engine oil on the

surface with oil groove of thrust washer. position the

surface with oil groove towards the cylinder body and the

surface with oil groove towards crankshaft.

——During installing crankshaft, engine oil should be

applied main journal, connecting rod journal, thrust

surface and bearing half.

——The character like 1,2,3,4,5 are casted on the top of

main bearing cap and also an arrow. During assembling,

install them from the front according to the sequence. At

the same time, have the arrow pointing to the front end

surface of cylinder block. The width of main bearing cap

1,2,4,5 is same, but the width of main bearing cap 3 is

larger than others.

The main bearing cap is retained by rabbet. It is

press fit between rabbet and cylinder body. The press fit

clearance is 0.025 — 0.145mm. After installation, the

surface of the first and the fifth main bearing caps should

be even or lower than the front and back end surface of

cylinder body.

40