Chery S11 / Chery QQ. Manual - part 268

Chery QQ Maintenance Manual Transmission System

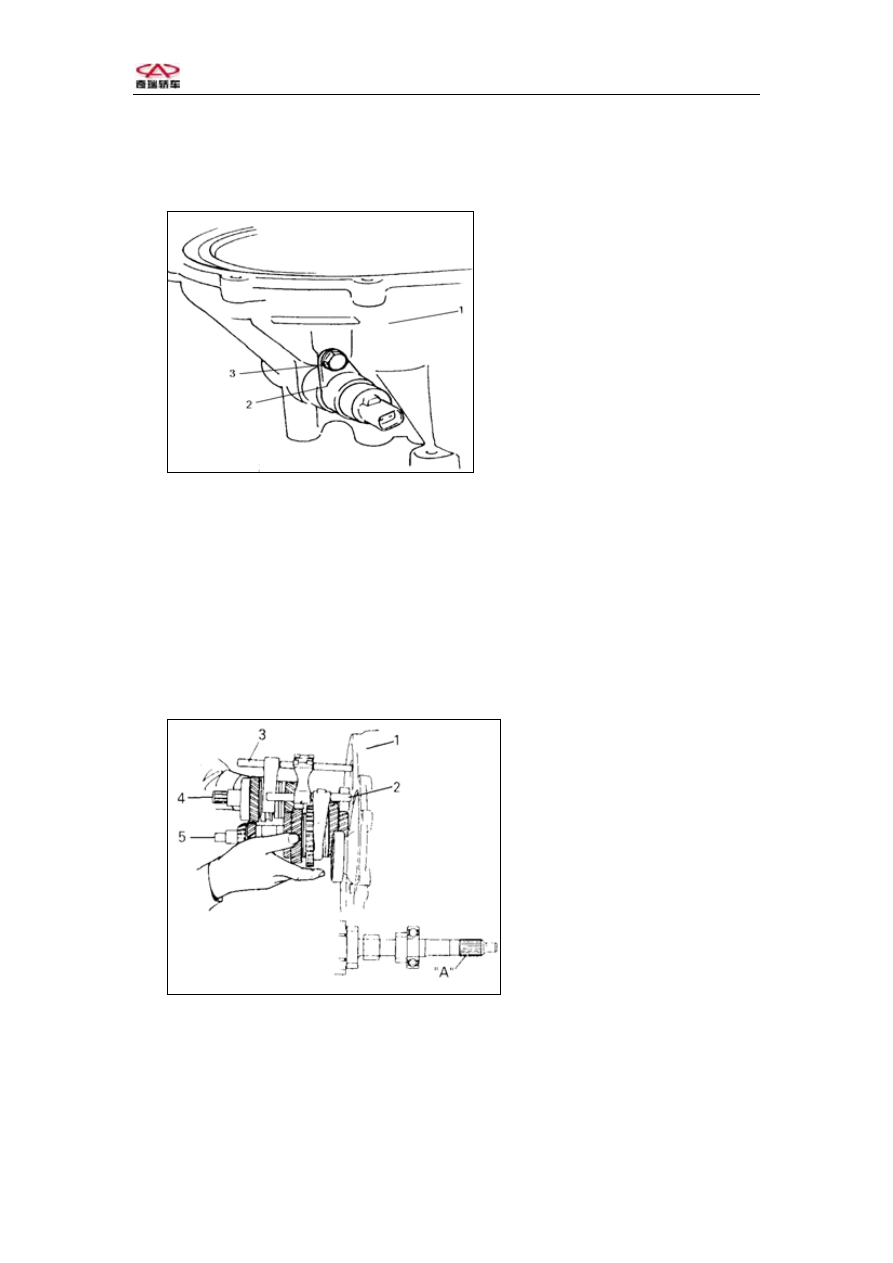

2、Spread lubricant on the “O” ring and gear, install the speedometer driven gear

assembly,and then screw down the torque.

Torque:8~12 N·m

1-Clutch case

2-Speedometer driven gear

assembly

3-Bolt

Fig.3-65

Notice: When installing speedometer driven gear, turn the differential ring driven

gear lightly to joggle the gear. Do not knock the cracks on the speedometer case,

otherwise the case may be broken.

3、Hold the input shaft assembly、output shaft assembly、1st、2nd shift fork

assembly and 3rd、4th Shift fork assembly and fix them on the clutch case.

Notice: Use hammer to rivet the input shaft right bearing into clutch case。

Be sure output shaft and differential ring driven gear are joggled。

Notice:In order to protect oil seal,twine the insulating tape to input shaft

splined hub。

1-Clutch case

2-1st 、 2nd Shift fork

shaft assembly

3-3rd 、 4th Shift fork

shaft assembly

4-Input shaft assembly

5-Output shaft assembly

Fig.3-66

4、Install the reverse shift fork, screw down the bolt。

Torque :18~28 N·m

Notice:When installing the reverse shift fork, keep the distance 5mm from the end of

shift fork and the shaft hole.

-84-